Method for producing high calorific value coal based fuel by using low calorific value coal

A technology of coal-based fuel and low calorific value, which is applied in the direction of fuel, solid fuel, petroleum industry, etc., can solve the problems of low calorific value coal unusable, insufficient resource utilization, large environmental pollution, etc., to achieve reduced emissions, good combustion performance, Effect of reducing soot blackness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

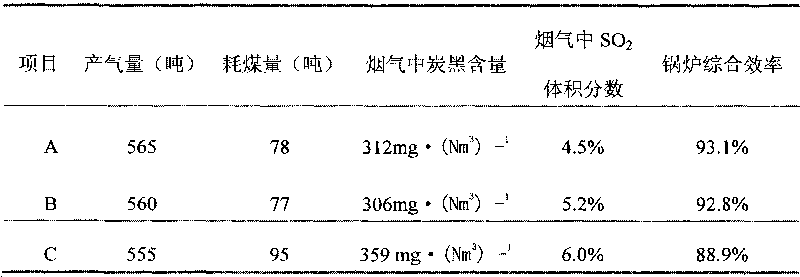

Examples

Embodiment 1

[0013] Under normal temperature and pressure, weigh 3 parts of potassium permanganate, 5 parts of potassium chlorate, 3 parts of quicklime, 1 part of potassium hydroxide, and 3 parts of calcium chloride by weight, grind them into 80-150 mesh particles, and add 5 parts of residual oil and 85 parts of low calorific value coal, and mix them evenly in the mixer.

Embodiment 2

[0015] Under normal temperature and pressure, weigh 5 parts of potassium permanganate, 3 parts of potassium chlorate, 6 parts of quicklime, 3 parts of potassium hydroxide, and 1 part of calcium chloride by weight, grind them into 80-150 mesh particles, and add 10 parts of residual oil and 65 parts of low calorific value coal, and mix evenly in the mixer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com