Quenching and tempering building furnace

A quenching, tempering, and tempering furnace technology, applied in the field of heat treatment, can solve the problems of thermal energy waste, heat dissipation, and discharge outside the furnace, and achieve the effect of ensuring temperature uniformity, reducing heat dissipation, and saving floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

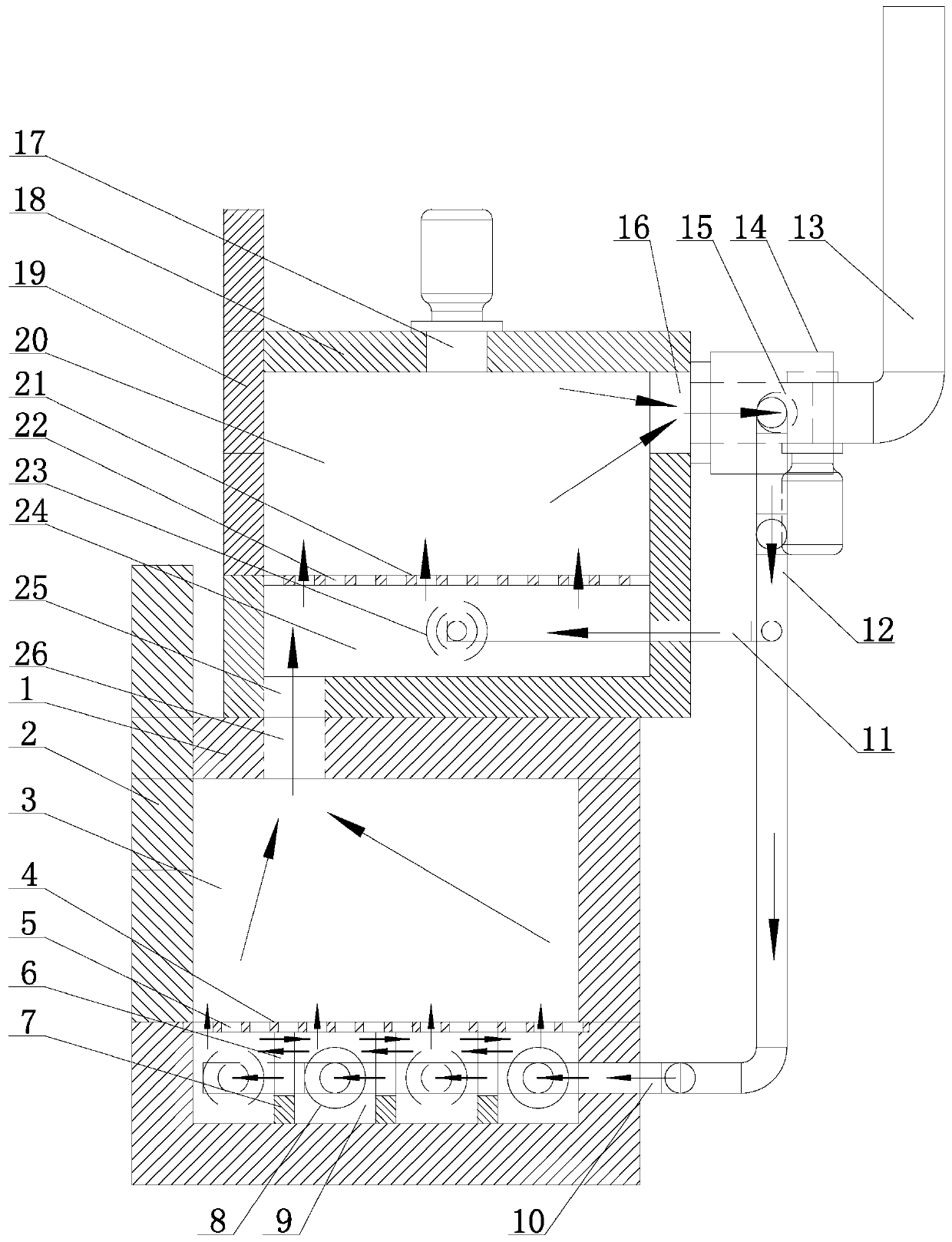

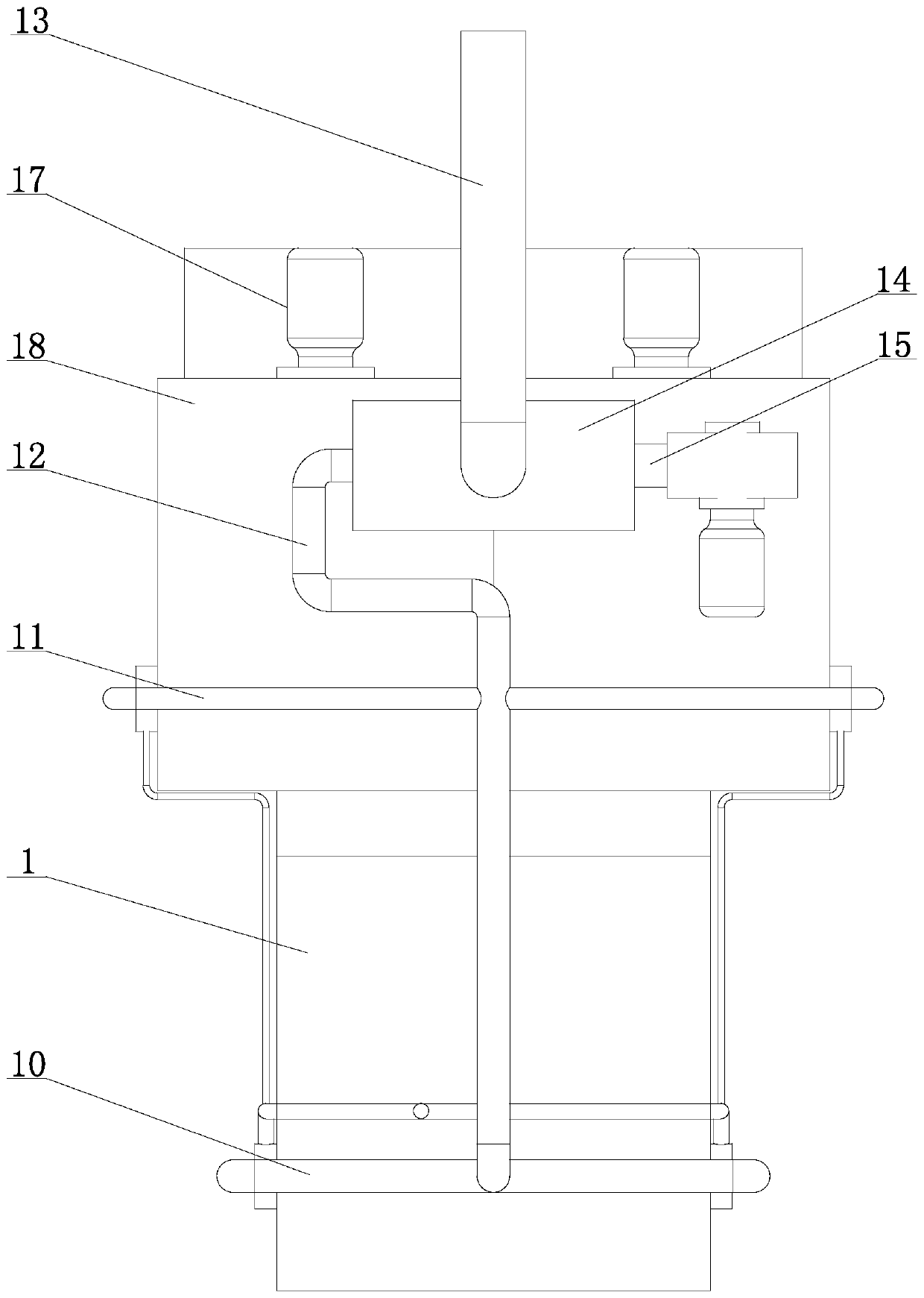

[0034] Such as figure 1 , 2 As shown, in the quenching and tempering building furnace in the present embodiment, the tempering furnace 18 is arranged on the top of the quenching furnace 1, the outlet of the chimney 26 of the quenching furnace 1 is arranged on the top of the quenching furnace 3, and the furnace bottom of the tempering furnace 18 is provided with the quenching furnace. The chimney 26 outlet of the chimney 1 corresponds to the air inlet 25, and the chimney 26 outlet is directly connected to the air inlet 25 at the furnace bottom of the tempering furnace 18.

[0035] By placing the tempering furnace 18 on the top of the quenching furnace 1, the floor space is saved; connecting the quenching furnace 1 and the tempering furnace 18 can make the high-temperature flue gas discharged from the exit of the chimney 26 of the quenching furnace 1 go upward to the intake air at the bottom of the tempering furnace 18 port 25, all the waste heat of the exhaust gas in the quenc...

Embodiment 2

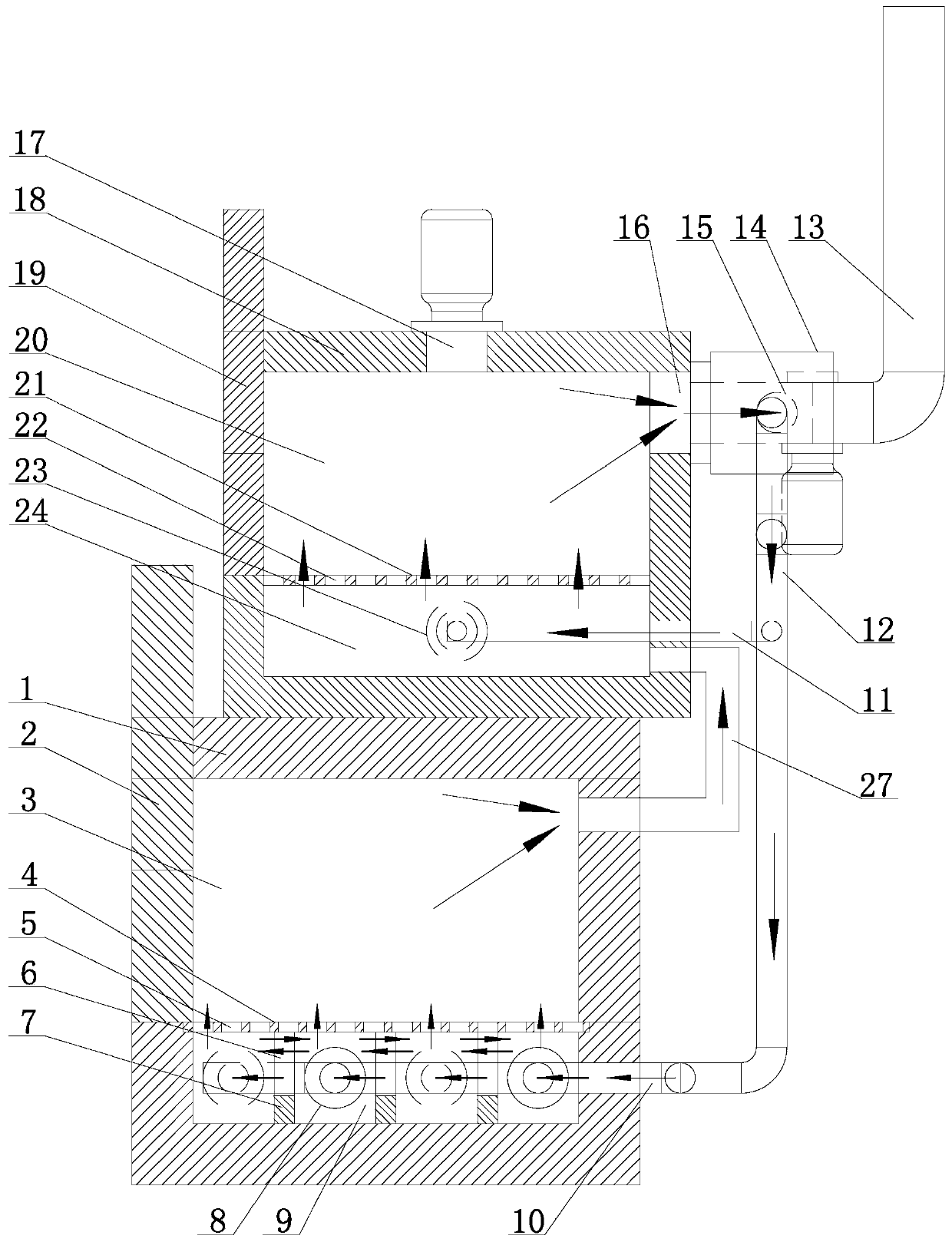

[0044] Such as image 3 As shown, in the quenching and tempering building furnace in the present embodiment, the tempering furnace 18 is arranged on the top of the quenching furnace 1, and the outlet of the chimney 26 of the quenching furnace 1 is arranged on the furnace wall on the right side of the quenching furnace 3, and the same side of the tempering furnace 18 The furnace wall (i.e. the right furnace wall) is provided with an air inlet 25 corresponding to the outlet of the chimney 26 of the quenching furnace 1, and the outlet of the chimney 26 is communicated with the air inlet 25 of the tempering furnace 18 through a pipeline 27, that is, the outlet of the quenching furnace The high-temperature flue gas discharged from the chimney 26 is discharged into the tempering furnace 18 through the pipe 27. Other structures are the same as in Embodiment 1. In this embodiment, all the waste heat of the exhaust gas from the quenching furnace will also be discharged into the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com