Aluminum alloy toughening method based on pulse current

A pulsed current, aluminum alloy technology, applied in the field of material processing and preparation, can solve problems such as difficult to apply to industrial production, difficult operation, unfavorable plasticity, etc., and achieve outstanding contributions, improved comprehensive mechanical properties, and excellent tensile strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

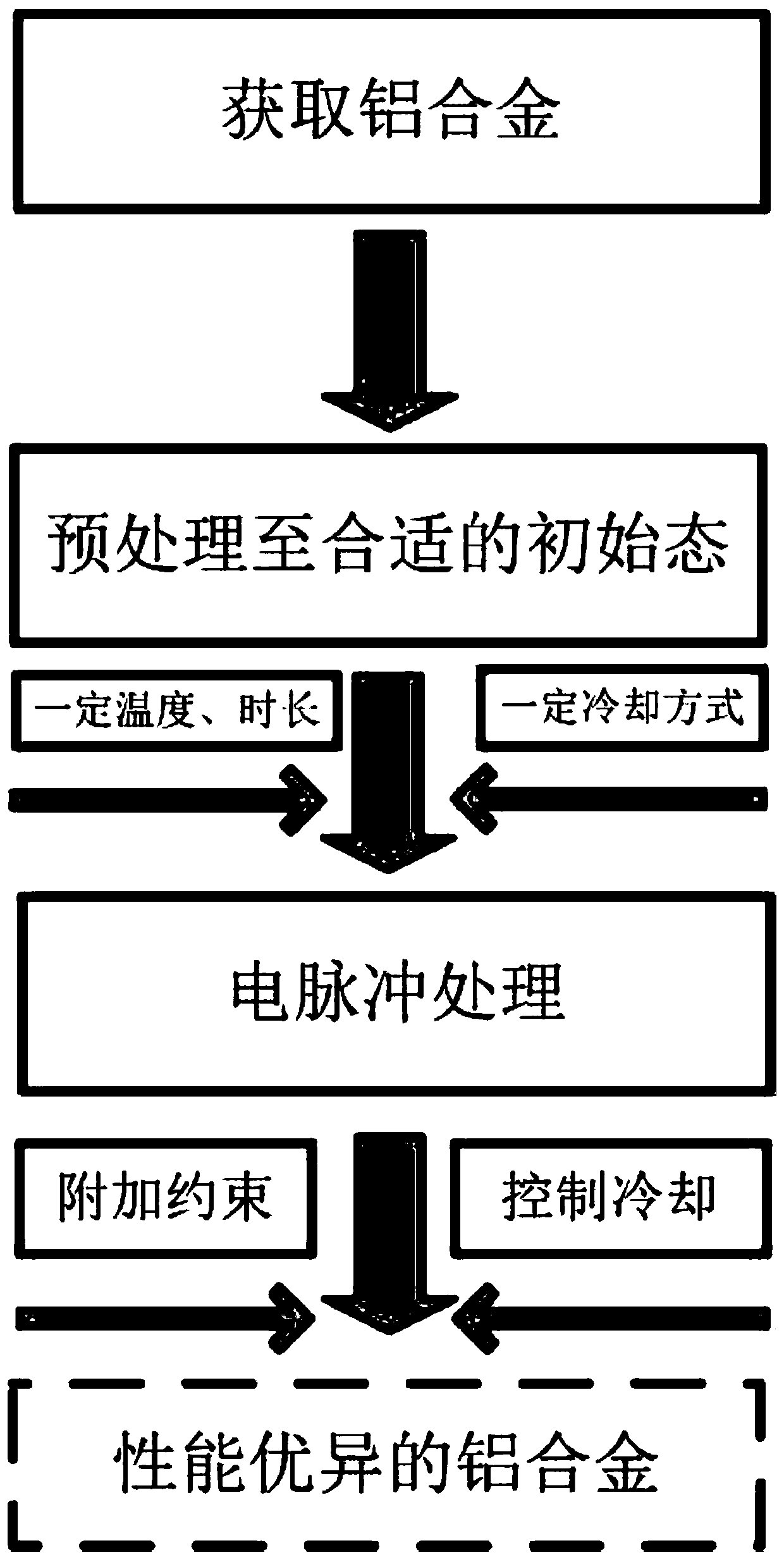

Method used

Image

Examples

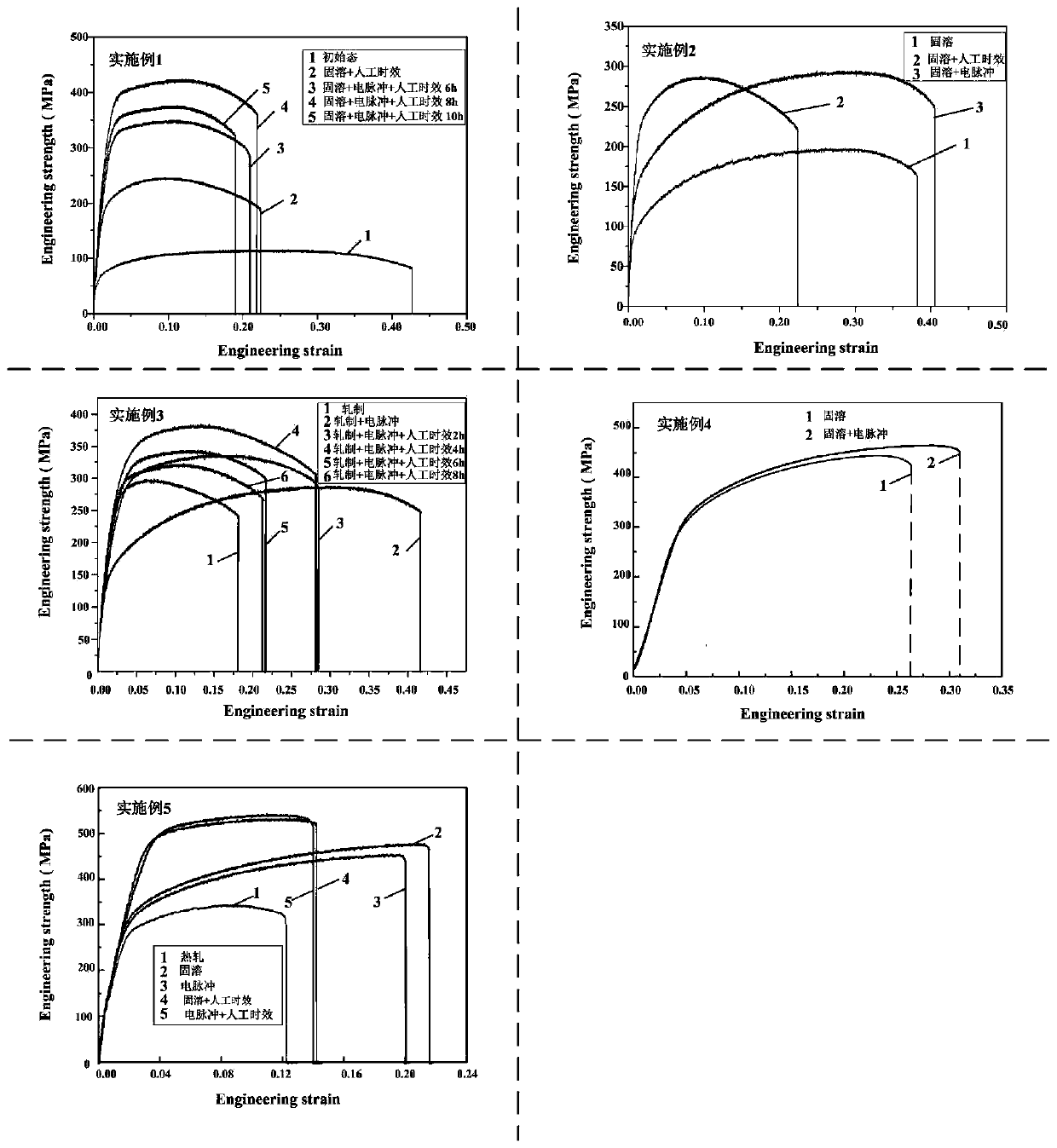

Embodiment 1

[0029] Preparation of high-strength 6000-series aluminum alloys.

[0030] In this embodiment, a method for strengthening and toughening aluminum alloy based on pulse current includes the following steps:

[0031] Step 1: Obtain a 6061 aluminum alloy plate, the mass percentage of which is: 0.88% Mg, 0.64% Si, 0.43% Fe, 0.24% Cu, 0.13% Cr, and the balance of Al.

[0032] Step 2, the 6061 aluminum alloy plate is pretreated before the experiment. The commercially available rolled 6061 aluminum alloy was cut into 130mm*200mm*10mm by wire electric discharge machine, and it was subjected to stress relief annealing at 510°C for 5 hours in a resistance furnace and cooled to room temperature with the furnace.

[0033] Step 3: Process the 6061 aluminum alloy into a suitable size. Cut the annealed 6061 aluminum alloy into sheet samples of 65mm*10mm*3mm with a wire electric discharge machine.

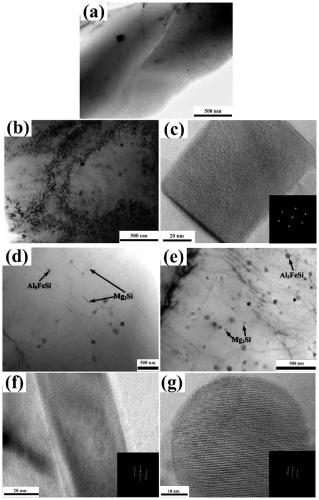

[0034] Step 4. The treatment method of combining traditional treatment and electric pulse tre...

Embodiment 2

[0041] Preparation of high ductility 6000 series aluminum alloy.

[0042] In this embodiment, a method for strengthening and toughening aluminum alloy based on pulse current includes the following steps:

[0043] Step 1: Obtain a 6061 aluminum alloy plate, the mass percentage of which is: 0.88% Mg, 0.64% Si, 0.43% Fe, 0.24% Cu, 0.13% Cr, and the balance of Al.

[0044] Step 2, the 6061 aluminum alloy plate is pretreated before the experiment. The commercially available rolled 6061 aluminum alloy was cut into 130mm*200mm*10mm by wire electric discharge machine, and it was subjected to stress relief annealing at 510°C for 5 hours in a resistance furnace and cooled to room temperature with the furnace.

[0045] Step 3: Process the 6061 aluminum alloy into a suitable size. Cut the 6061 aluminum alloy into sheet samples of 65mm*10mm*3mm with a wire electric discharge machine.

[0046] Step 4. The treatment method of combining traditional treatment and electric pulse treatment of...

Embodiment 3

[0053] Preparation of high-strength, high-plasticity 6000-series aluminum alloys.

[0054] In this embodiment, a method for strengthening and toughening aluminum alloy based on pulse current includes the following steps:

[0055] Step 1: Obtain a 6061 aluminum alloy plate, the mass percentage of which is: 0.88% Mg, 0.64% Si, 0.43% Fe, 0.24% Cu, 0.13% Cr, and the balance of Al.

[0056] Step 2, the 6061 aluminum alloy plate is pretreated before the experiment. The commercially available rolled 6061 aluminum alloy was cut into 130mm*200mm*10mm by wire electric discharge machine, and it was subjected to stress relief annealing at 510°C for 5 hours in a resistance furnace and cooled to room temperature with the furnace.

[0057] Step 3: Process the 6061 aluminum alloy into a suitable size. Cut the 6061 aluminum alloy into a sheet sample of 65mm*10mm*5mm with a wire electric discharge machine.

[0058] Step 4: Roll the 6061 aluminum alloy at room temperature with a reduction of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com