Air intake system of gasoline engine and air inflow control method

A technology of air intake system and gasoline engine, applied in electrical control, engine control, charging system, etc., can solve problems such as poor fuel economy, inability to realize multi-level control of intake air, and inability to reduce throttling loss of throttle body, etc., to achieve The effect of meeting the needs of all working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

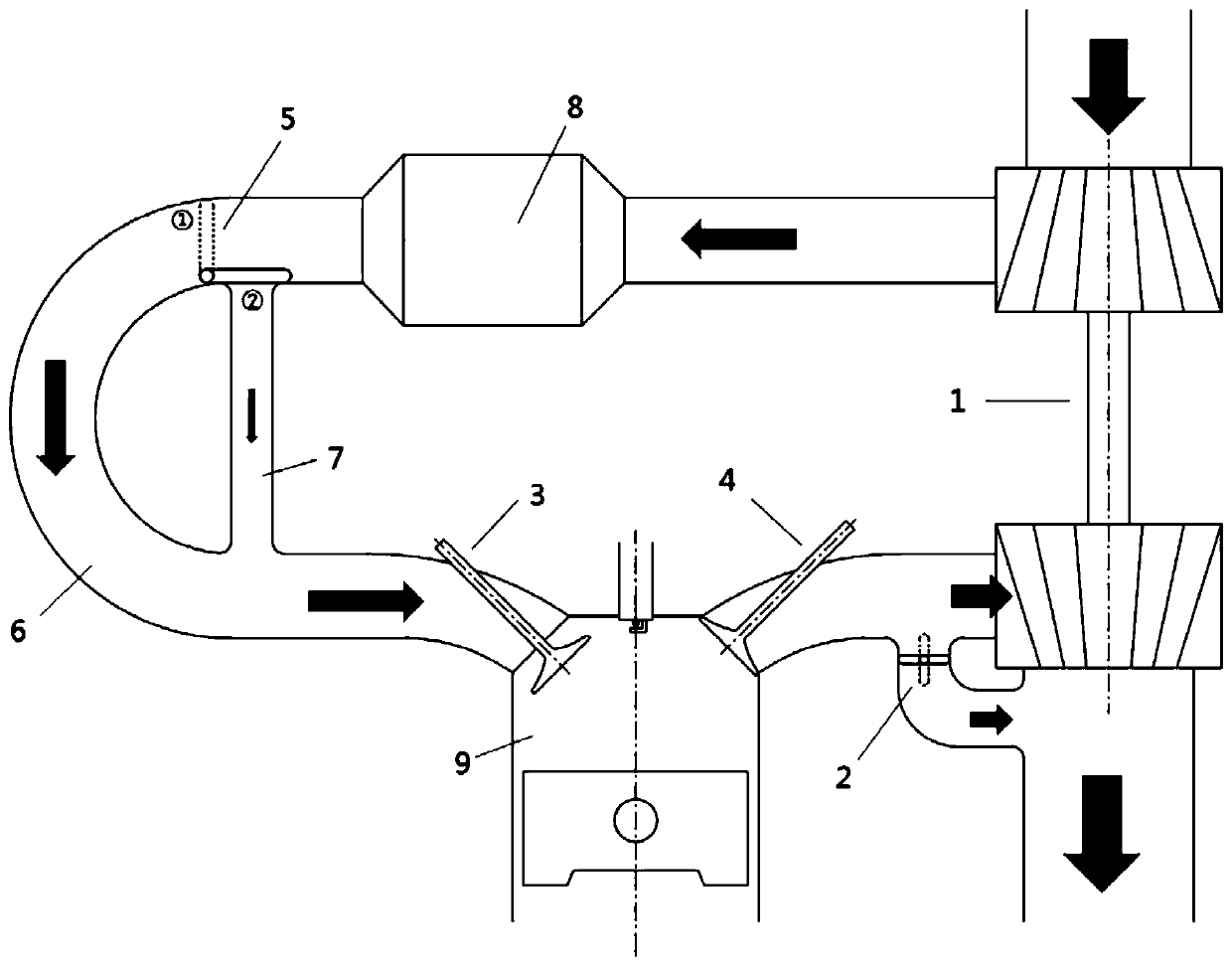

[0033] This embodiment proposes a gasoline engine air intake system without a throttle body and an intake air volume control method, by controlling the intake switching valve 5, variable valve timing, variable valve lift, and exhaust gas from the turbocharger 1 Bypass valve 2, to achieve the control of the intake charge. The schematic diagram of the air intake system is as follows: figure 1 shown.

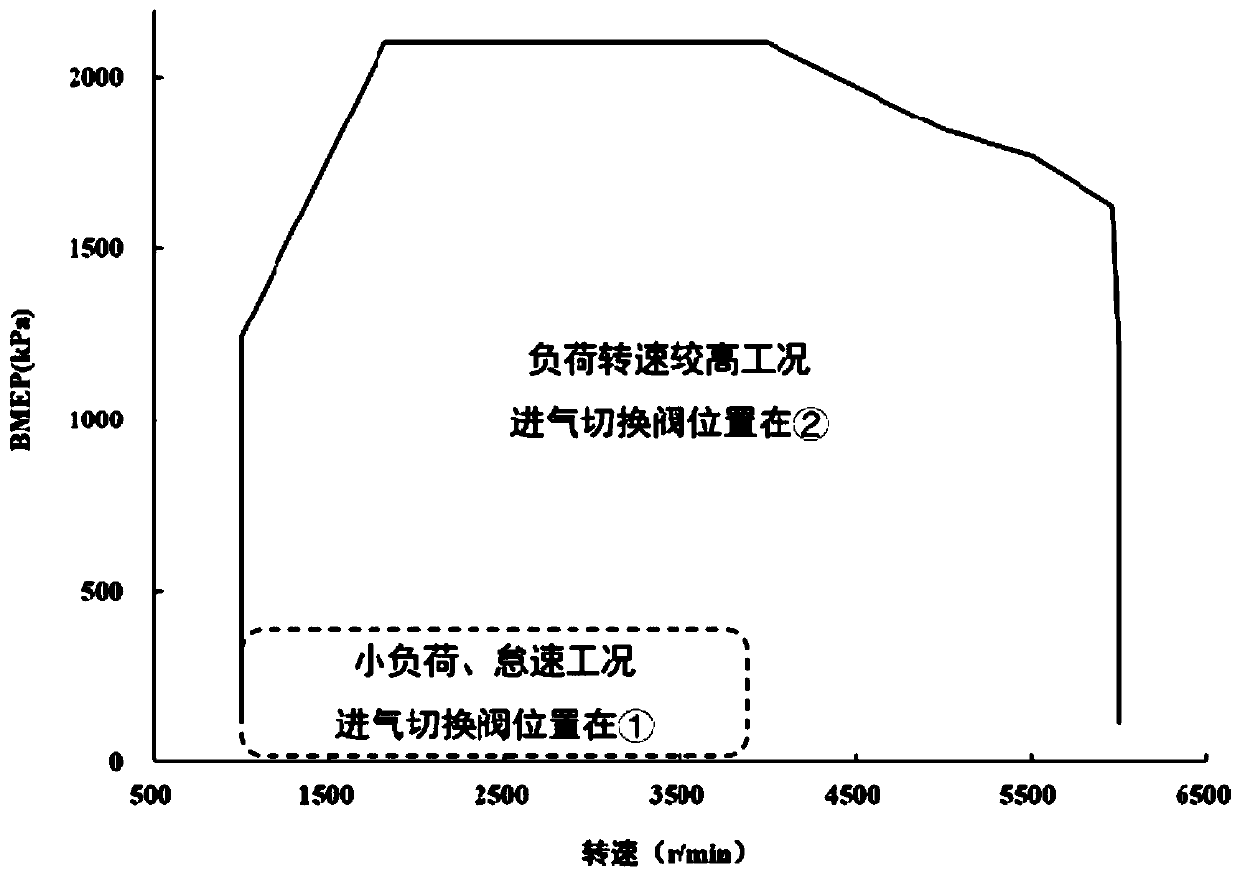

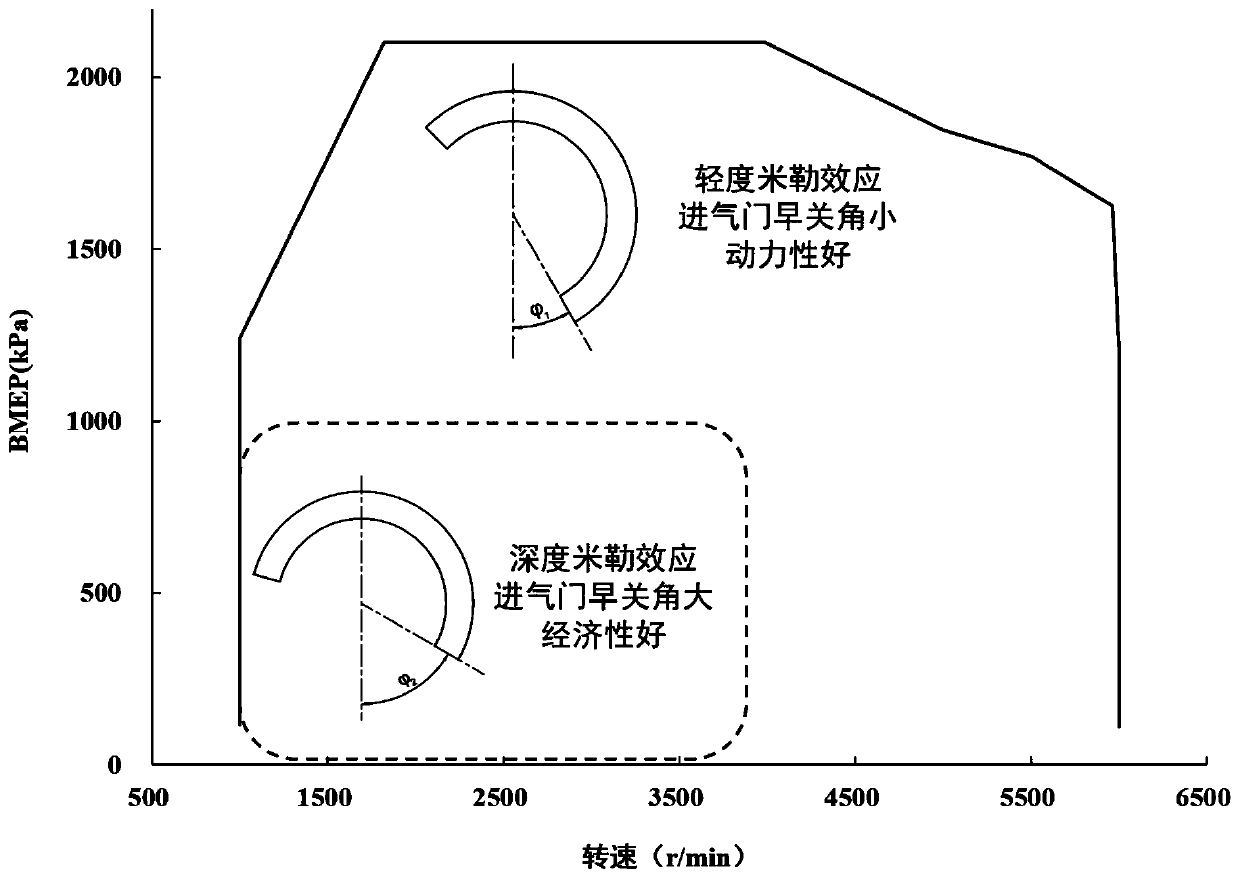

[0034] A gasoline engine air intake system, including an electronic control unit, a pipeline, a turbocharger 1 and a variable valve, the variable valve includes an intake valve 3 and an exhaust valve 4, and the turbocharger 1 includes a wastegate valve 2, The system also includes an intake switching valve 5, which is placed in the pipeline between the intake port of the turbocharger 1 and the intake valve 3, and the electronic control unit controls the intake switching valve 5 to realize two intake volume modes When working, the air enters the cylinder 9 through the intake port o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com