Large-core-number optical cable for pipelines

A technology with a large number of cores and optical cables, applied in the directions of light guides, optics, optical components, etc., can solve the problems of insufficient capacity to meet demand, security risks, data errors, etc., to save costs, save pipe space, and improve the effect of bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

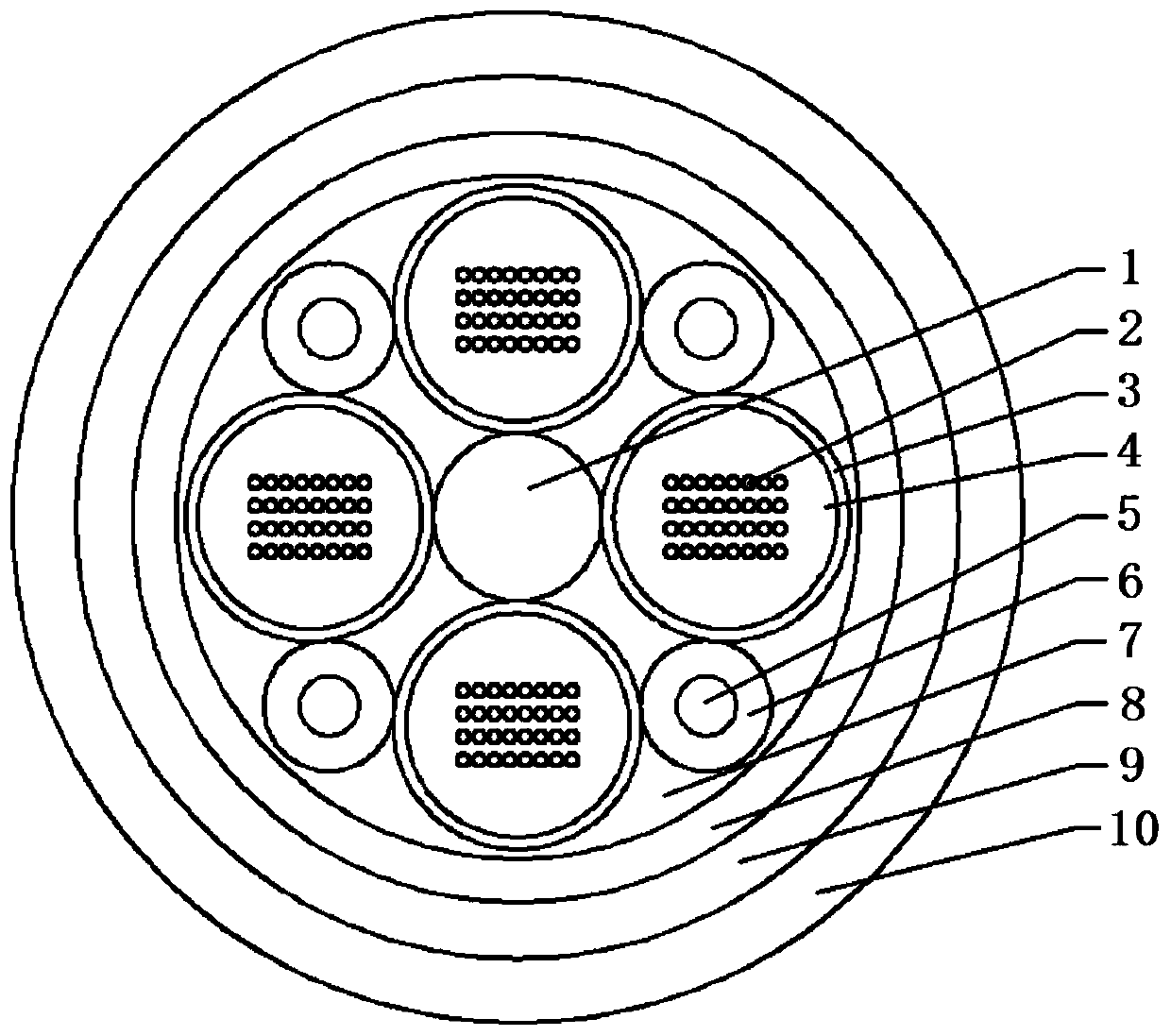

[0026] This embodiment is to design a large-core optical cable for pipelines with more than 2000 optical fiber cores to replace the existing pipeline optical cable with an outer diameter of 20mm and 1052 cores. choose as figure 1 The technical scheme of the cross-sectional schematic diagram of the large-core optical cable for the pipeline is shown. The large-core optical cable for the pipeline includes the central transmission unit 1, the optical cable sub-unit and the optical cable temperature sensing unit. With the central transmission unit 1 as the center, 4 optical cables The sub-units and 4 optical cable temperature sensing units are alternately arranged around the central transmission unit 1 to form a circular cross-section cable core in the form of SZ twisting;

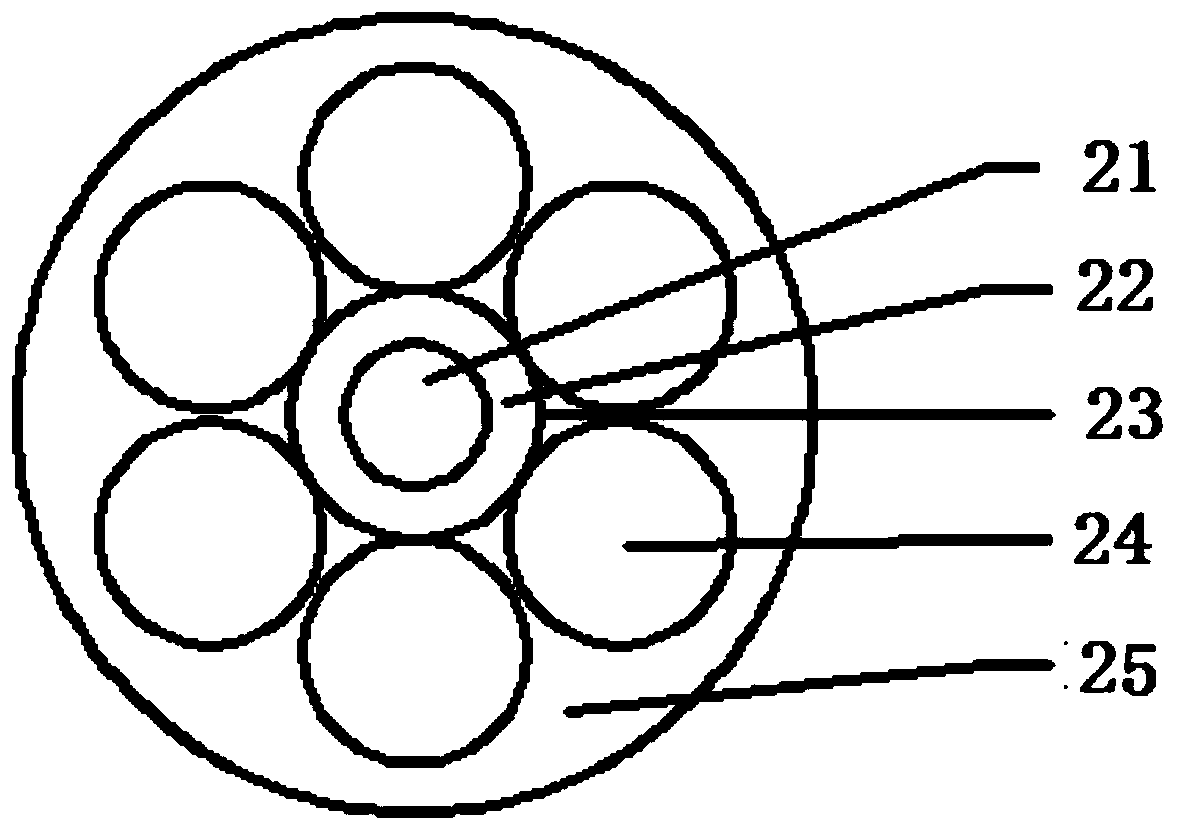

[0027] Such as figure 2 As shown in the cross-sectional schematic diagram of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com