Method for synthesizing high-dispersity magnetic nano ellipsoid

A magnetic nanometer and highly dispersive technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of hindering the mass transfer of the system and the surrounding space, increasing costs and energy waste, and low dispersion of magnetic particle colloids. Achieve good colloidal dispersibility, save energy and improve dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

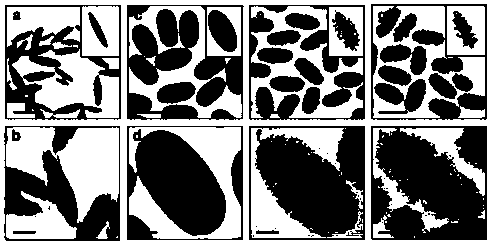

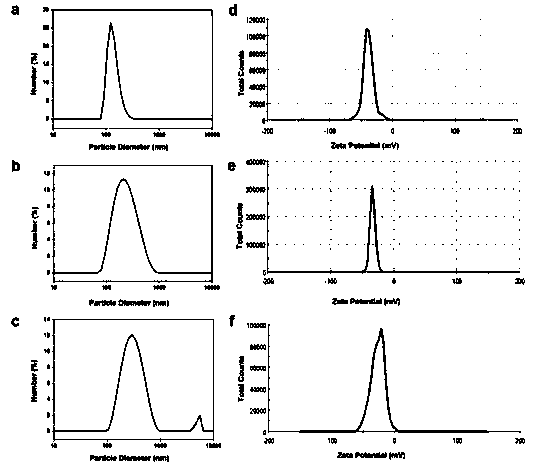

[0019] This example demonstrates the implementation process of one of the high-dispersion magnetic nano-ellipsoids. exist figure 1 are the TEM images of the morphology changes of the particles during each synthesis process. figure 2 Then it shows that the porous α-Fe 2 o 3 @SiO 2 The Zeta potentials of the obtained products are respectively -38, -34 and -26mV, which shows that α-Fe can be reduced at 300°C in the present invention 2 o 3 @SiO 2 The magnetic nano ellipsoid material is obtained, and the dispersibility is the best. In the present invention, the magnetic material particles are preferably prepared according to the method of hydrolyzing iron salt in the document J.Am.Chem.Soc. Dissolve sodium dihydrogen phosphate in 200 ml of water, and let it stand in a 100-degree oven for 2 days to obtain an ellipsoidal α-Fe with a size of 150 nm in major axis and 40 nm in minor axis 2 o 3 Particles, by adjusting the composition of the reaction solution and the reaction te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com