Positive electrode sheet of lithium ion capacitor, lithium ion capacitor and negative electrode lithium pre-intercalation method thereof

A lithium ion and capacitor technology, applied in the field of lithium ion capacitors, can solve the problems of shortened battery cycle life and peeling off of the positive electrode coating layer, and achieve the effects of long cycle life, improved energy density, and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

[0055] Embodiments 1-9 relate to a lithium ion capacitor, and the lithium ion capacitor is prepared according to the following steps:

[0056] S1: Preparation of negative electrode sheet: Mix soft carbon, conductive carbon black and PVDF according to a certain mass ratio, and evenly disperse them into N-methylpyrrolidone to prepare a slurry, and then coat the slurry on the copper foil, pass Drying, rolling, slitting and other processes are used to make negative electrode sheets.

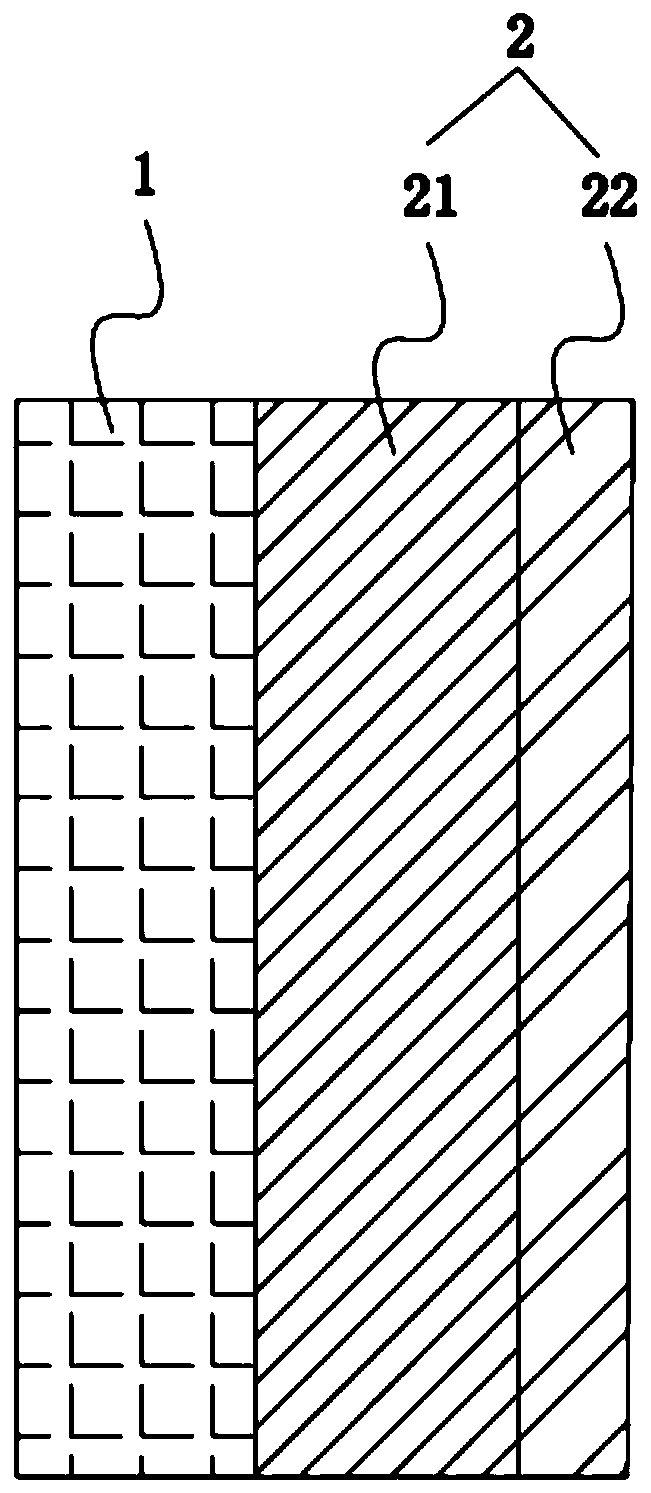

[0057] S2: Preparation of positive electrode sheet: Mix activated carbon, conductive carbon black, and PVDF according to a certain mass ratio, and evenly disperse them into N-methylpyrrolidone to prepare a slurry, and then coat the slurry on aluminum foil. Rolling, slitting and other processes are used to form a positive electrode current collector coated with a coating layer of positive electrode active material, and then lithium nitride and PVDF are mixed in a glove box filled with high-purity argo...

Embodiment 10

[0064] This embodiment relates to a lithium ion capacitor, and the lithium ion capacitor is prepared according to the following steps:

[0065] S1. Preparation of negative electrode sheet: Mix soft carbon, conductive carbon black, and PTFE in a mass ratio of 8:1:1, and evenly disperse them into N-methylpyrrolidone to prepare a slurry, and then coat the slurry on the copper foil Then, through drying, rolling, slitting and other processes, the negative electrode sheet is made.

[0066] S2. Preparation of positive electrode sheet: Mix activated carbon, conductive carbon black, and PTFE in a mass ratio of 8:1:1, and evenly disperse them into N-methylpyrrolidone to prepare a slurry, and then coat the slurry on aluminum foil, Through drying, rolling, slitting and other processes, the positive electrode current collector coated with the positive electrode active material coating layer is made, and then lithium nitride and PTFE are mixed in a glove box filled with high-purity argon ac...

Embodiment 11

[0071] This embodiment relates to a lithium ion capacitor, and the lithium ion capacitor is prepared according to the following steps:

[0072] S1. Preparation of negative electrode sheet: Mix soft carbon, conductive carbon black, and CMC in a mass ratio of 7:2:1, and evenly disperse them into an aqueous solution to prepare a slurry, then coat the slurry on the copper foil, and dry it by drying , rolling, slitting and other processes to make negative electrode sheets.

[0073]S2. Preparation of positive electrode sheet: Activated carbon, conductive carbon black, and CMC are mixed in a mass ratio of 7:1:2, and uniformly dispersed into an aqueous solution to obtain a slurry, and then the slurry is coated on an aluminum foil, dried and rolled Pressing, slitting and other processes are used to make a positive electrode current collector coated with a coating layer of positive active material, and then in a glove box filled with high-purity argon gas, lithium nitride and PVDF are m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com