Preparation method of 3D printed PLGA intervertebral fusion cage coated with calcium phosphate cement

A technology of calcium phosphate bone cement and intervertebral cage, which is applied in 3D printing, coating, additive manufacturing and other directions, can solve the problems of too fast degradation of 3D printing cage, unmaintainable mechanical strength, enlargement of printing gap, etc. Biocompatibility, reduced contact, improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

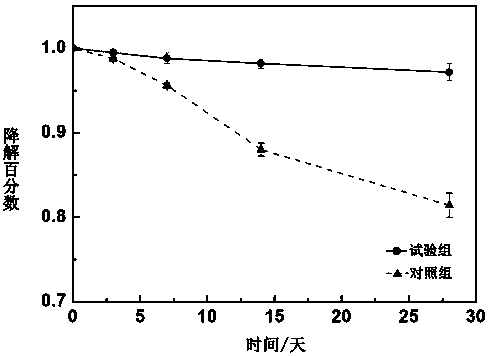

[0035]A 3D printed PLGA intervertebral fusion device coated with calcium phosphate bone cement. The degradable polyester PLGA intervertebral fusion device was prepared by 3D printing technology, and then the polymer surface was coated with calcium phosphate bone cement and the printing gap was filled. Phosphoric acid After the calcium bone cement is cured to form a hydroxyapatite coating, it is prepared as follows:

[0036] 1. Preparation of 3D printed PLGA intervertebral fusion cage:

[0037] Use PLGA (Mw=20W) as the printing "ink", the 3D printer is Bio-Architect ®-WS, the material is placed in the barrel of the high-temperature nozzle, the printing needle is 170μm, and the printing parameters are set: each layer is printed in parallel, and the gap is 0.2 mm, the Z-axis direction is increased layer by layer by 0.15mm, the layers are vertically cross-stacked, the printing temperature is 190°C, the extrusion speed is set to 2mm / s, and the temperature of the receiving platform ...

Embodiment 2

[0042] A 3D printed PLGA intervertebral fusion device coated with calcium phosphate bone cement, prepared according to the following steps:

[0043] 1. Preparation of 3D printed PLGA intervertebral fusion cage:

[0044] Use PLGA (Mw=20W) as the printing "ink", the 3D printer is Bio-Architect ®-WS, the material is placed in the barrel of the high-temperature nozzle, the printing needle is 170μm, and the printing parameters are set: each layer is printed in parallel, and the gap is 0.25 mm, the Z-axis direction is increased layer by layer by 0.15mm, the layers are vertically cross-stacked, the printing temperature is 190°C, the extrusion speed is set to 2mm / s, and the temperature of the receiving platform is 30°C. The cervical intervertebral fusion cage was printed, and this fusion cage was used as the control group.

[0045] 2. The preparation of gelatin-modified α-TCP is the same as in Example 1.

[0046] 3. Prepare Na with a mass fraction of 2.5% by magnetic stirring at roo...

Embodiment 3

[0048] A 3D printed PLGA intervertebral fusion device coated with calcium phosphate bone cement, prepared according to the following steps:

[0049] 1. Preparation of 3D printed PLGA intervertebral fusion cage:

[0050] Use PLGA (Mw=20W) as the printing "ink", the 3D printer is Bio-Architect ®-WS, the material is placed in the barrel of the high-temperature nozzle, the printing needle is 170μm, and the printing parameters are set: each layer is printed in parallel, and the gap is 0.3 mm, the Z-axis direction is increased layer by layer by 0.15mm, the layers are vertically cross-stacked, the printing temperature is 190°C, the extrusion speed is set to 2mm / s, and the temperature of the receiving platform is 30°C. The cervical intervertebral fusion cage was printed, and this fusion cage was used as the control group.

[0051] 2. The preparation of gelatin-modified α-TCP is the same as in Example 1.

[0052] 3. Prepare Na with a mass fraction of 2.5% by magnetic stirring at room...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com