Small powder water slurry preparation/feeding apparatus and intelligent control

A technology of adding equipment and powder, which is applied in the field of solid slurry preparation/dosing equipment for small wastewater treatment stations, which can solve the problems of reducing the working intensity of feeding workers and dust pollution, and achieves a high degree of intelligence/automation and accurate feeding , good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

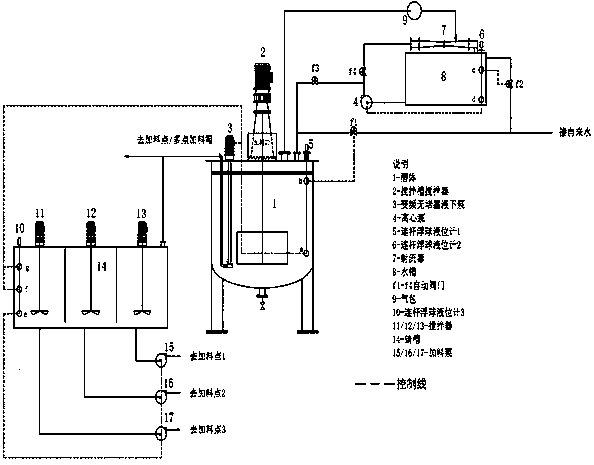

[0013] l. Press start key 1, valve f1 opens, valve 2 opens. 2. Tap water enters 1 and 4. When the liquid level of 5 reaches b, valve f1 automatically closes and an alarm informs the operator to add material. When the liquid level of 6 reaches c, valve f2 is automatically closed. 3. Start 2, start 4, add the powder in the bag from the feeding port, due to the vacuum formed by the jet, the powder that floats into the air during the feeding process is drawn into the ejector, mixed with the water in the ejector, and then taken Enter 8. 4. After the feeding is completed, press the start button 2, 3 to start, 3 is a submerged pump with a frequency modulation motor, set the flow rate through the inverter controlled by PLC, and feed to the feeding point or 13, when the liquid level of 5 drops To a, stop at 3, stop feeding to the feeding point, and stop at 2. 5. Valve f4 is closed, valve f3 is opened, water in 8 enters 1, when the liquid level of 6 drops to d, valve f3 is closed, an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap