Processing method of earphone dust-proof cover

A processing method and technology of dust cover, applied in the field of processing of earpiece dust cover, can solve the problems of complex processing procedure, unstable mesh structure, low product yield, etc., achieve stable microporous structure, and improve product yield. , Save the effect of weaving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

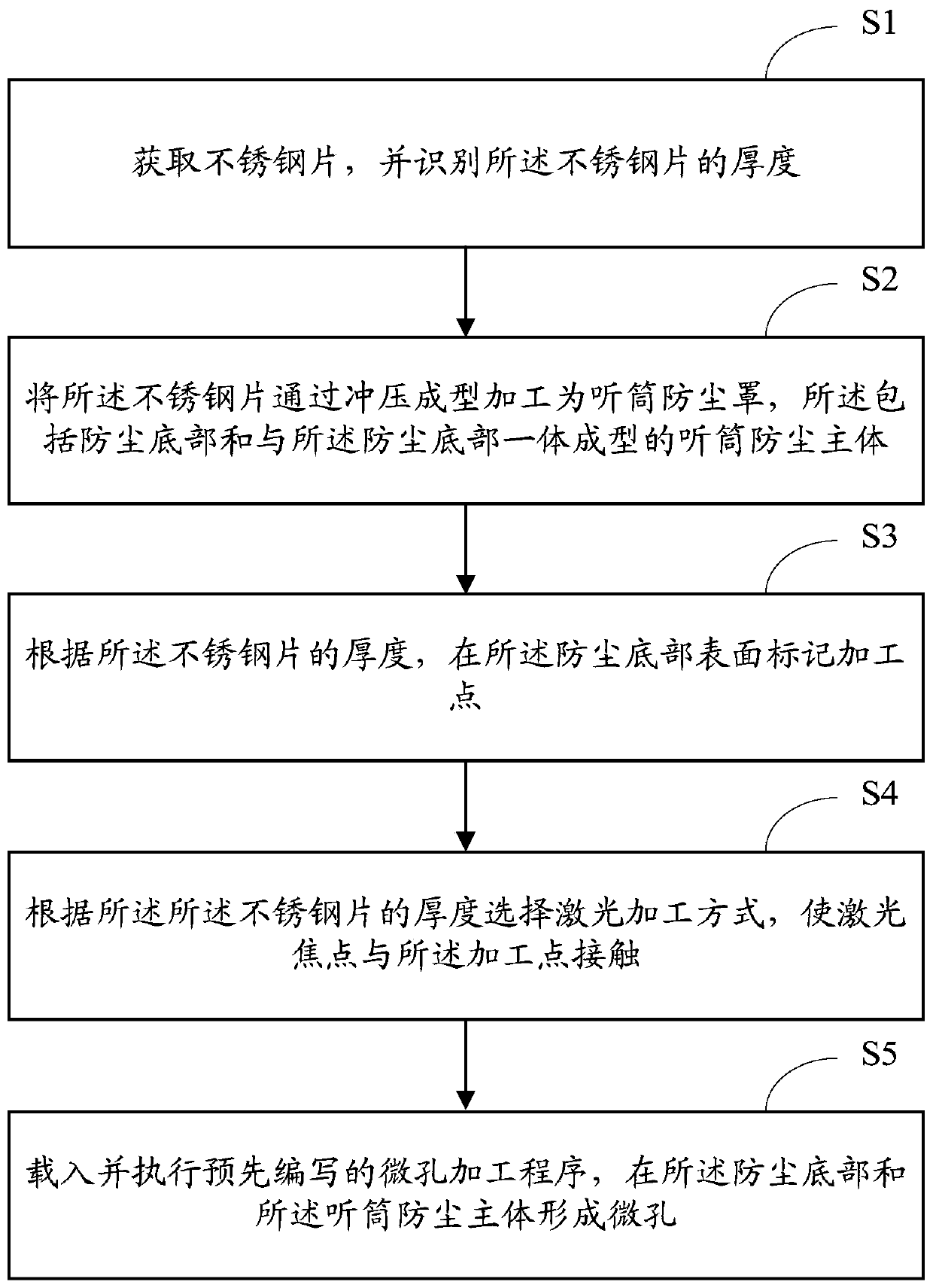

[0054] Such as figure 1 As shown, the embodiment of the present invention provides a method for processing the earpiece dust cover, including:

[0055] S1. Obtain a stainless steel sheet, and identify the thickness of the stainless steel sheet.

[0056]In the above step S1, the stainless steel sheet is used as the base material of the dustproof cover of the earpiece, one of the surfaces will be the surface of the dustproof bottom, and the other surface will be the surface of the dustproof main body of the earpiece. The above two surfaces in the stainless steel sheet are The two opposite surfaces, and the distance between the above two surfaces, is the thickness of the stainless steel sheet.

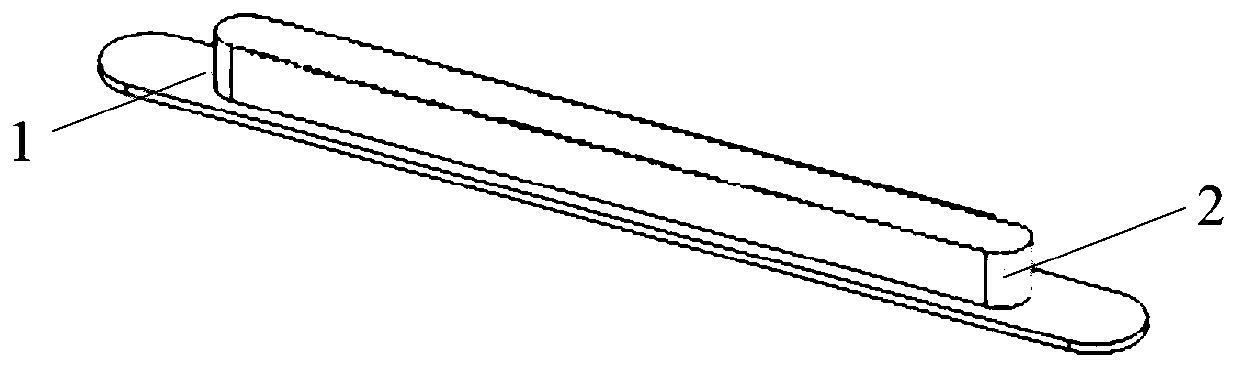

[0057] S2. Processing the stainless steel sheet into a dustproof cover for the earpiece by stamping and forming, the dustproof cover for the earpiece includes a dustproof bottom and a dustproof main body of the earpiece integrally formed with the dustproof bottom.

[0058] In the above ...

Embodiment 2

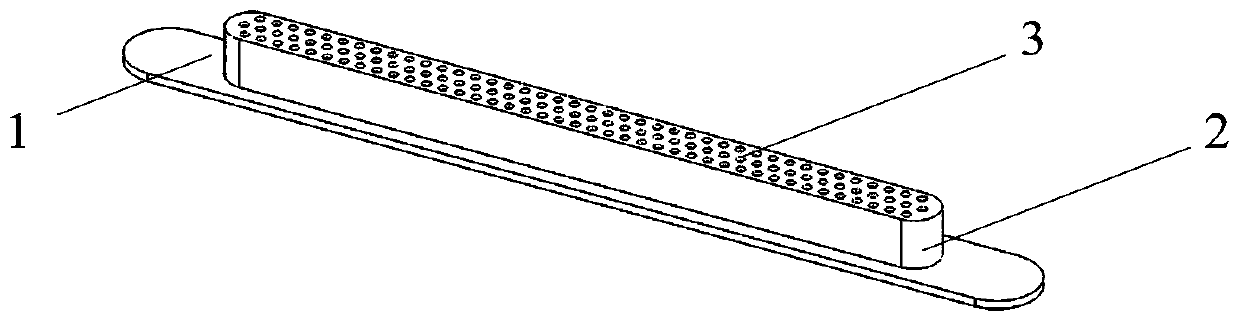

[0075] Such as Figure 4 As shown, the embodiment of the present invention also shows a schematic flowchart of the detailed implementation of step S3 in the method for processing the earpiece dust cover provided in the first embodiment.

[0076] In an embodiment of the present invention, step S3 may include:

[0077] S31. Using the processing point as the center point of the microhole.

[0078] S32. When marking the processing points on the surface of the dust-proof bottom, adjust the distance between the two processing points according to the thickness of the stainless steel sheet.

[0079] In the above step S31 and step S32, the distance between the two processing points is the sum of the diameter of the microhole and the preset spacing, and the preset spacing and the diameter of the microhole are the same as that of the stainless steel sheet corresponding to the thickness.

[0080] In a specific application, the distance between two processing points is the distance betw...

Embodiment 3

[0088] The embodiment of the present invention exemplarily shows two specific implementations of step S4 in the first embodiment, the first specific implementation is:

[0089] When the thickness of the stainless steel sheet is 0.07mm to 0.15mm, an ultraviolet picosecond laser with a wavelength of 355nm is used;

[0090] Adjust the laser processing parameters of the ultraviolet picosecond laser;

[0091] Adjusting the laser focal length of the ultraviolet picosecond laser so that the laser focus is in contact with the processing point;

[0092] The ultraviolet picosecond laser is used to successively peel off the stainless steel material at the processing point.

[0093] In specific applications, the maximum power of the ultraviolet picosecond laser is 8W, and the laser marking range is 100mm×100mm. The principle of this laser is to repeatedly act on the metal surface, so that the metal is peeled off one by one, and finally the desired effect is achieved. The advantage is the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com