A method of increasing the climbing ability of a support truck

A technology of support truck and climbing ability, which is applied in the field of coal mine machinery to achieve the effect of reducing driving torque, enhancing climbing ability and ensuring economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

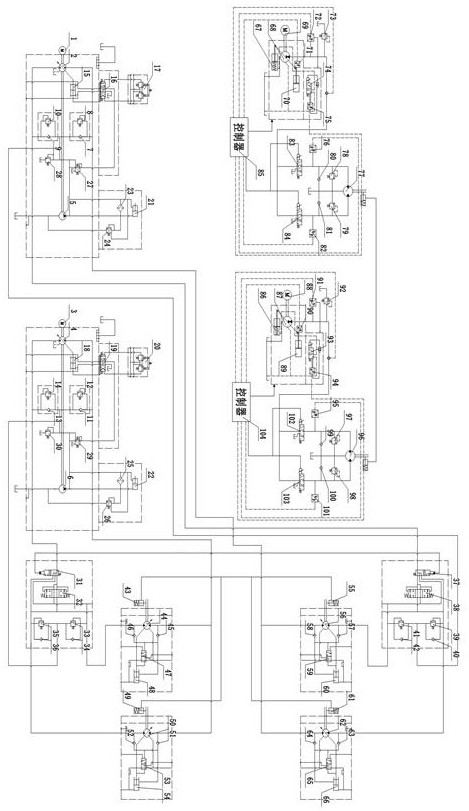

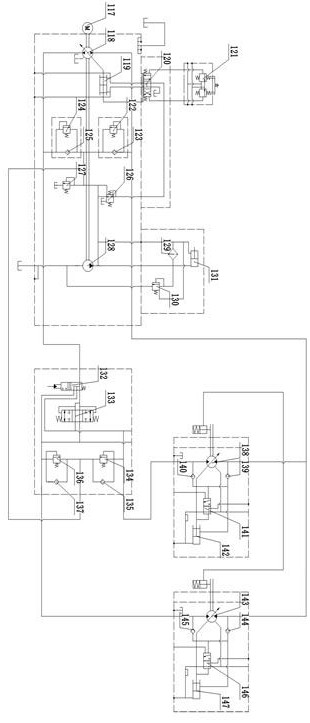

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

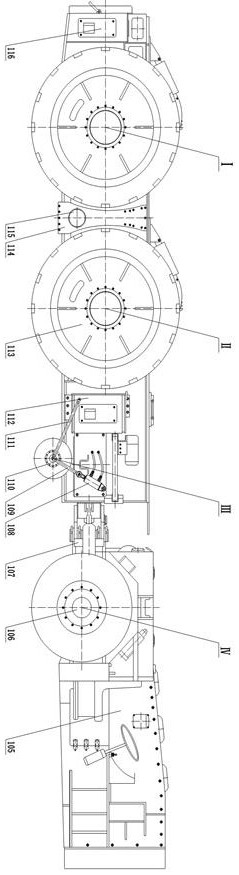

[0023] figure 1 Shown, the present invention is improved at Shanxi Coal Machinery Equipment Co., Ltd. WC55Y type support truck.

[0024] The front frame (105) is connected with the front wheel shaft (106), the front oil cylinder baffle plate (107) is connected with the front frame (105), the eleventh hydraulic cylinder (108) is connected with the connecting rod (109), and the connecting rod ( 109) is connected with the increased auxiliary driving wheel (110), the increased auxiliary driving wheel (110) is connected with the connecting rod (111), and the connecting rod (111) is connected with the rear frame (116). The rear frame (116) is connected with the rear wheel (113), the rear frame (116) is connected with the pivot bracket (114), the pivot bracket (114) is connected with the main shaft pin (115), and the rear anti-collision block (112) Link to the rear frame (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com