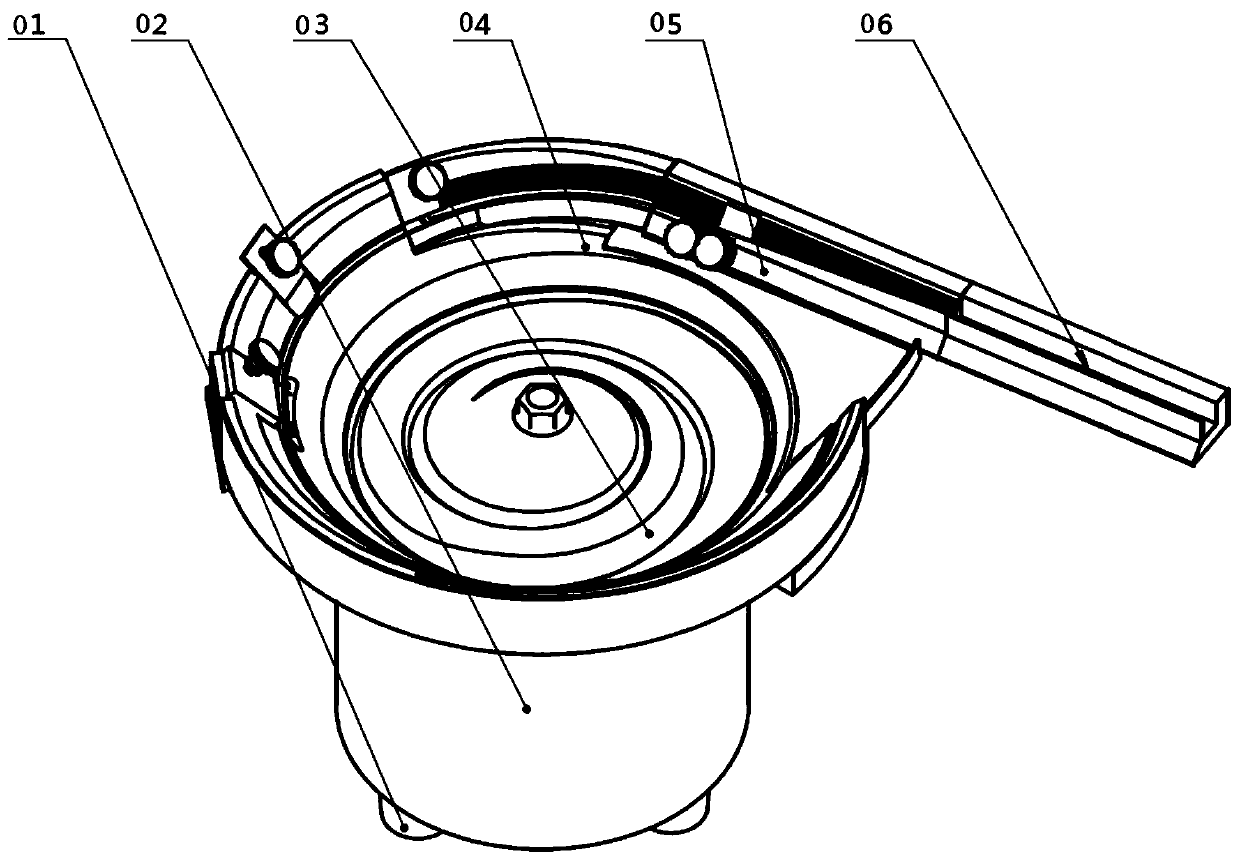

Specially-shaped plastic soft bottle material arranging device

A technology for material sorting and special-shaped applications, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems affecting bottle quality, bottle friction marks, low running speed, etc., to achieve a good production environment, less connecting parts , the effect of low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

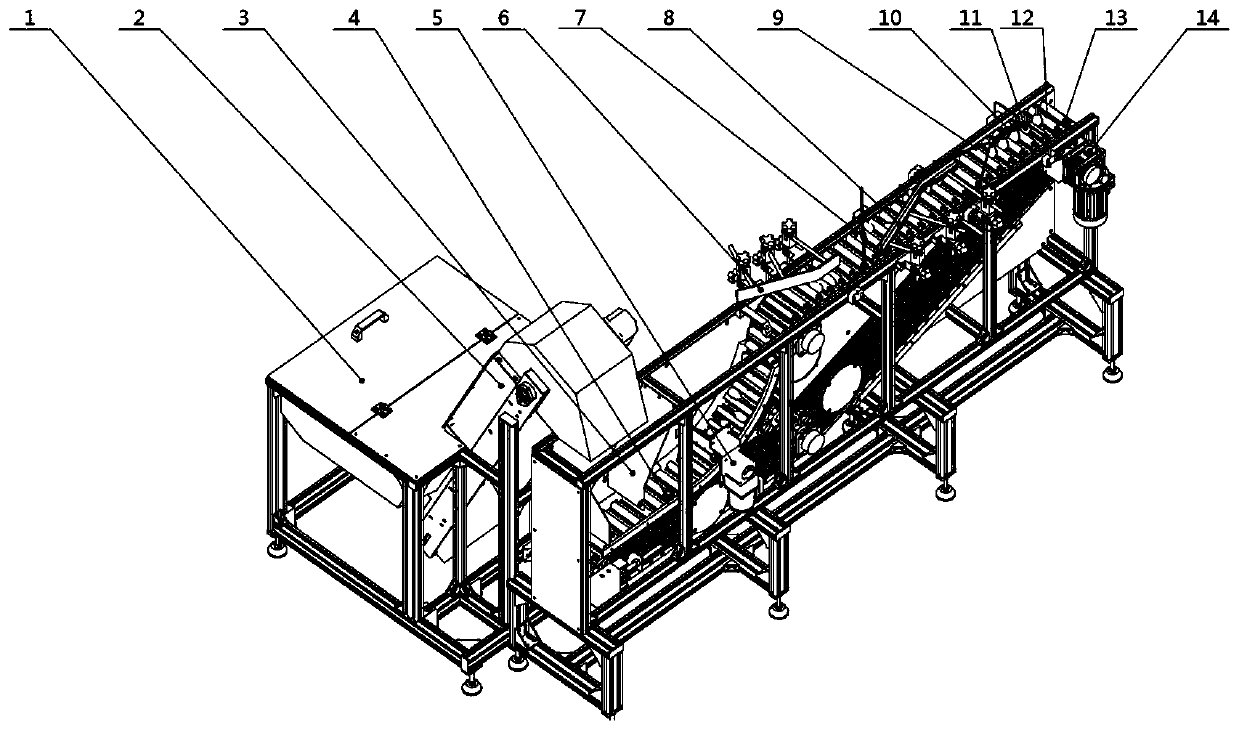

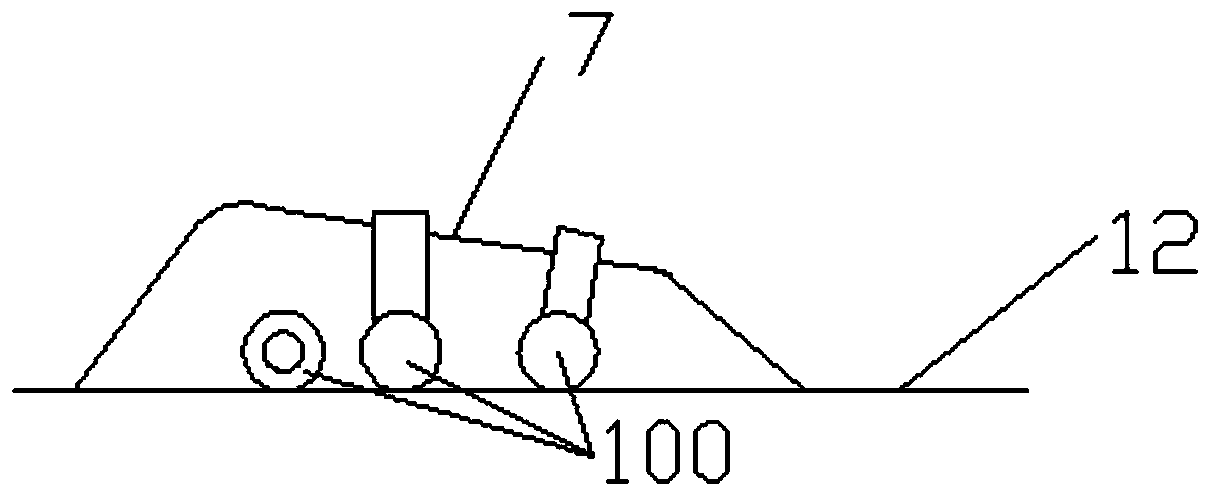

[0022] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

[0023] like Figure 5 As shown, the conveying plate chain is conveyed from A to B. In order to enable those skilled in the art to understand the application of the present invention more quickly and concisely, and also to facilitate the description of the shape, position and connection mode of the individual components in the content of the application of the present invention, According to the expressions and habits of those skilled in the art for the conventional conveying direction of conveying structures such as conveyor belts and plate chains, it is agreed that B is in front of A. Assuming that a person skilled in the art stands facing B and leaning against A, Then the right hand side of the person skilled in the art standing above is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com