Intelligent overturning dipping and conveying device and pretreatment electrophoresis overturning dipping system for vehicle body

A conveying device and intelligent technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as high cost, unfavorable market competition, complex structure, etc., to reduce operating costs, benefit environmental protection, The effect of reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

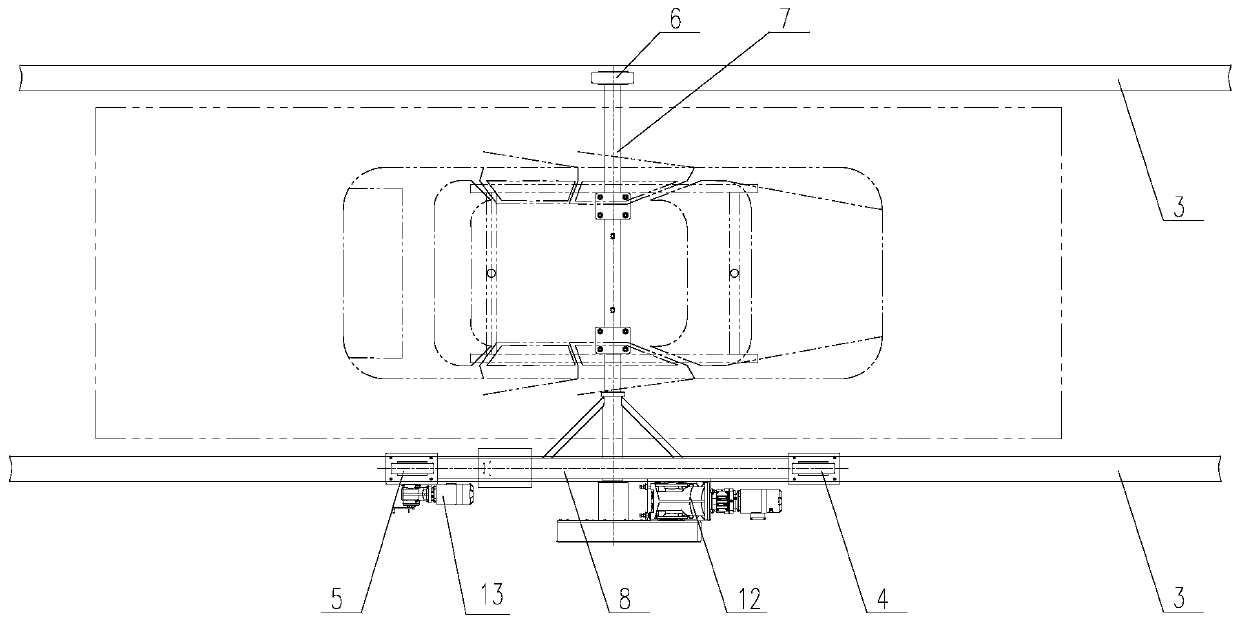

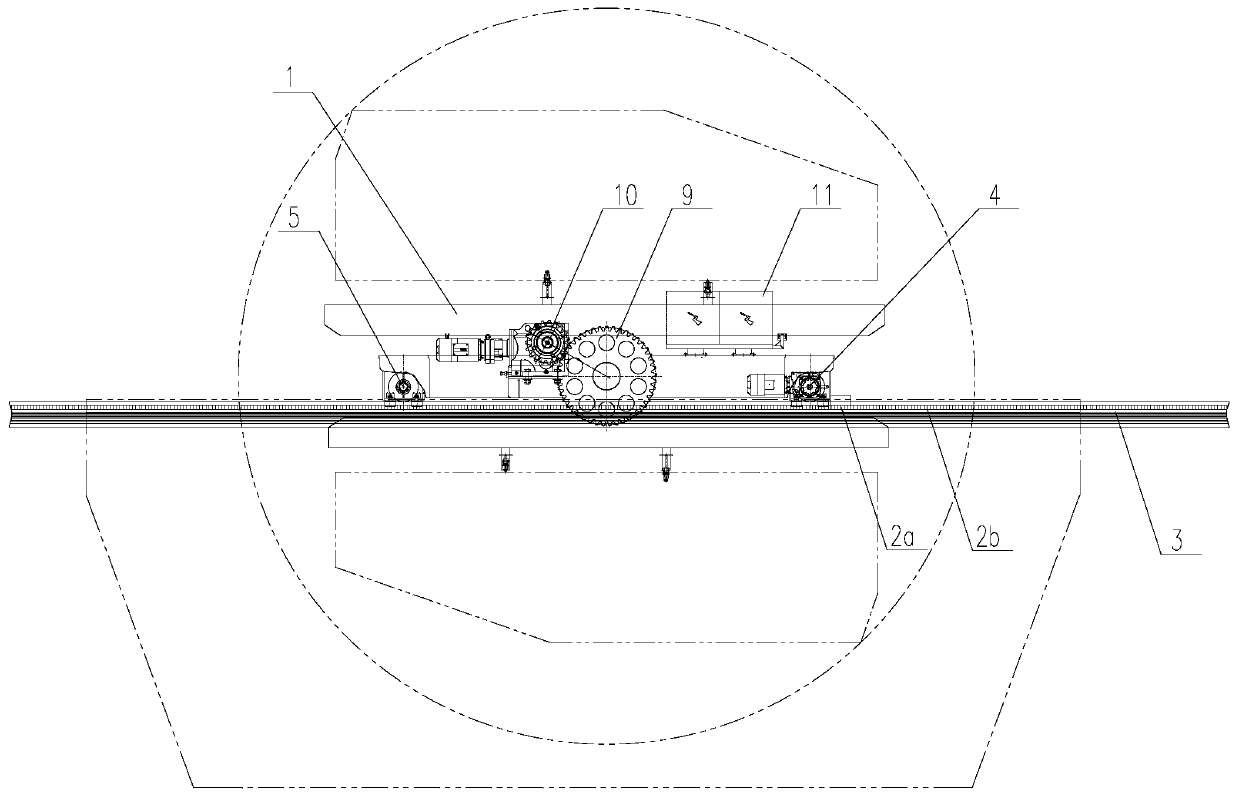

[0017] Such as figure 1 , figure 2 The shown intelligent overturning conveying device includes a pair of parallel running rails 3 and a T-shaped turning trolley that can automatically walk along the walking track 3. The T-shaped turning trolley includes a T-shaped side beam 8, a turning component and a turning platform 1. The T-shaped side beam 8 is set on one of the walking tracks 3 through two traveling wheels 4 and 5. The traveling wheels 4 and 5 are respectively driven by a traveling motor 13. The T-shaped side beam 8 includes a main beam And the secondary beam perpendicular to the main beam, the turning assembly is arranged on the T-shaped side beam 8, the turning assembly includes a rotating shaft 7, a differential gear set and a turning motor 12, one end of the rotating shaft 7 is connected to the T-shaped side beam 8 The sub-beam is movably connected, and the other end of the rotating shaft 7 is set on another walking track 3 opposite to the T-shaped side beam 8 thro...

Embodiment 2

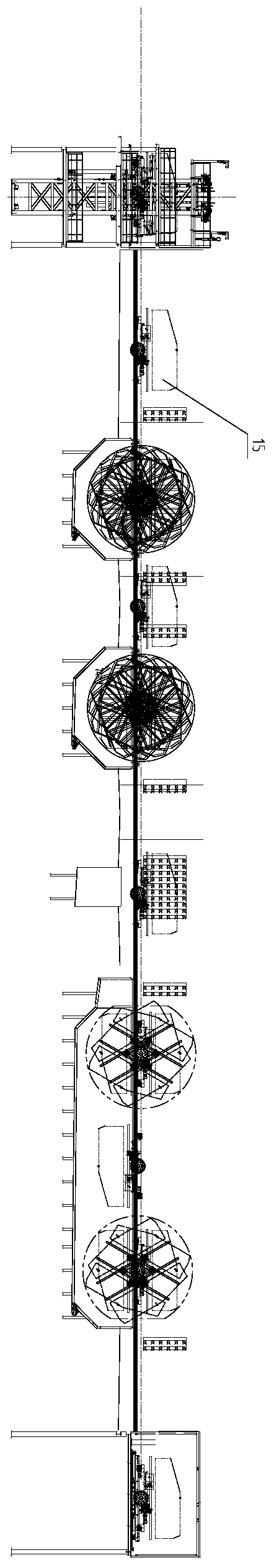

[0021] Such as image 3 The electrophoresis dipping system for the pre-treatment of the car body is provided with a plurality of intelligent dipping conveying devices 15 of the present invention. Process treatment station operation; stop at the entrance of the tank body or turn over during operation and immerse the body into the process tank, and process according to the process treatment requirements; in the process dipping tank, the workpiece and the trolley are in the dipping tank according to the process time requirements Run forward; at the position where the workpiece exits the trough, the overturning trolley is the same as the overturning trolley at the place of entering the trough, and it is turned over during stop or running to make the body exit the trough at the end of the dipping tank; after all the technological processes are completed, the body is transferred on the trolley The off-line is transferred to the ground conveyor system; the empty trolley passes the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com