Magnetic self-flocculation material with Raman-enhanced properties and its preparation method and application

A self-flocculation and magnetic technology, applied in the analysis of materials, Raman scattering, material excitation analysis, etc., can solve the problems of low recovery efficiency and easy residual water, and achieve the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

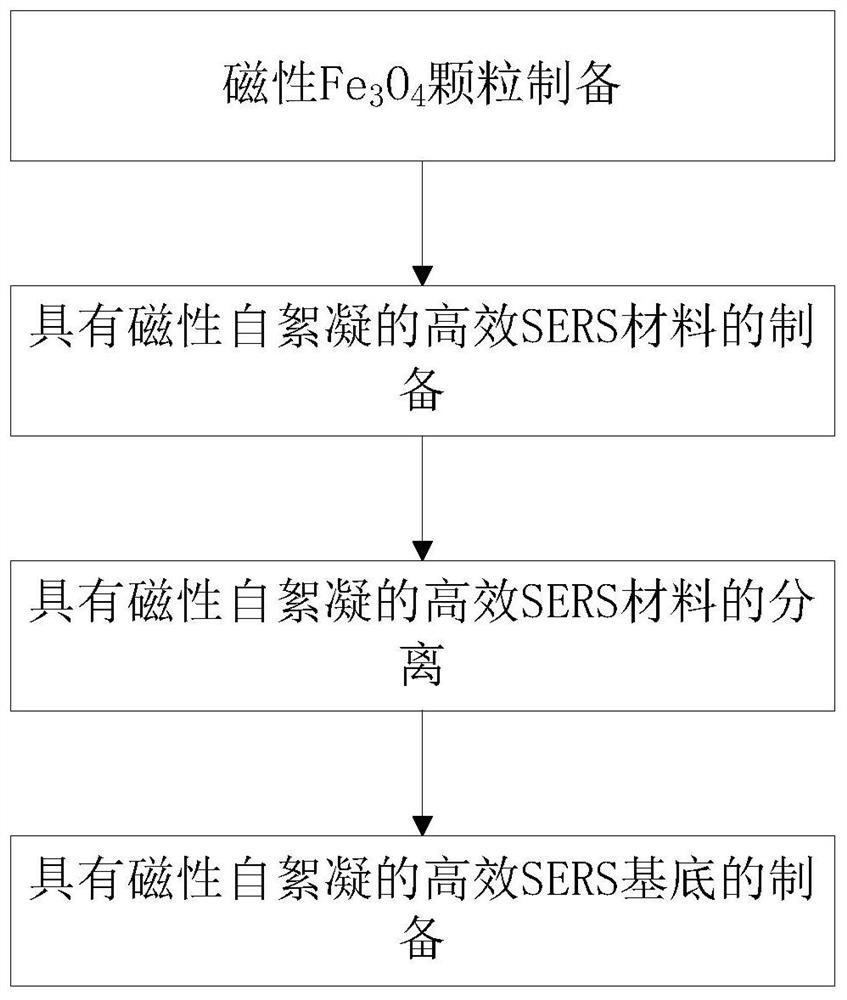

[0024] A method for preparing a magnetic self-flocculation material with Raman enhanced properties, comprising the following steps:

[0025] (1) Preparation of magnetic Fe 3 o 4 Granules: Take 0.5-1.0g of ferrous sulfate heptahydrate and 0.2-0.5g of citric acid, add 5-10mL of deionized water, stir evenly, pour into the lined polytetrafluoroethylene, then add 8-12mL of 40-50% wt hydrazine hydrate, then put it into the reaction kettle at 140-160 ℃ for 6-8 h in a constant temperature drying oven, collect the black precipitate with a magnet after cooling, and wash it repeatedly for 3-5 times to obtain the magnetic Fe 3 o 4 particles.

[0026] (2) Preparation of highly efficient SERS materials with magnetic self-flocculation: take the magnetic Fe from step (1) 3 o 4 Particles, after dispersing with deionized water, add 0.02-0.05 g polyethyleneimine (PEI), and ultrasonically disperse evenly; mix 5-10 mL of 50-70 mM silver nitrate solution and 2-4 mL of 0.04-0.06 g / mL polyviny...

Embodiment 1

[0031] This example provides a method for preparing materials with magnetic self-flocculation efficient extraction and recovery and SERS enhancement properties, such as figure 1 shown, including the following steps:

[0032] (1) Preparation of magnetic Fe 3 o 4 Particles: Dissolve 0.8 g of ferrous sulfate heptahydrate and 0.3 g of citric acid in 10 mL of deionized water, stir evenly, pour into the lined polytetrafluoroethylene, then add 10 mL of 45%wt hydrazine hydrate, and then put it into the reaction kettle Put it in a constant temperature drying oven at 150 °C for 8 h, collect the black precipitate with a magnet after cooling, and wash it repeatedly for 3-5 times to obtain the magnetic Fe 3 o 4 particles.

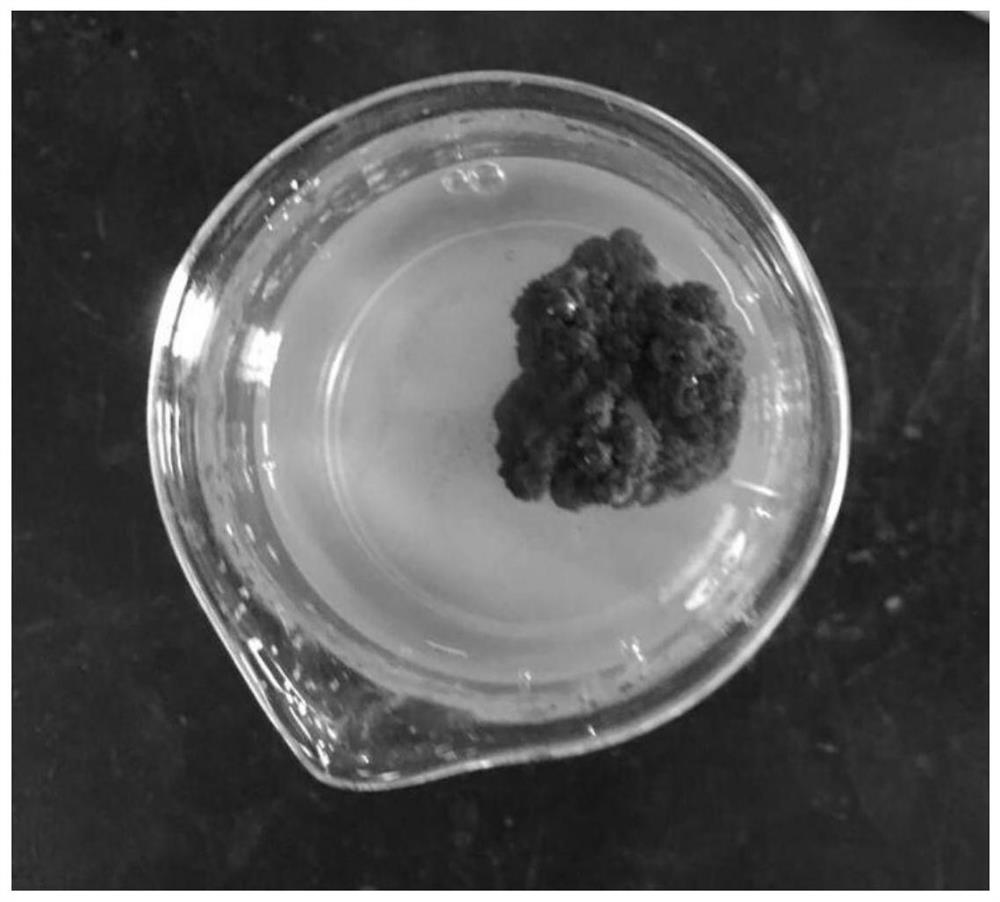

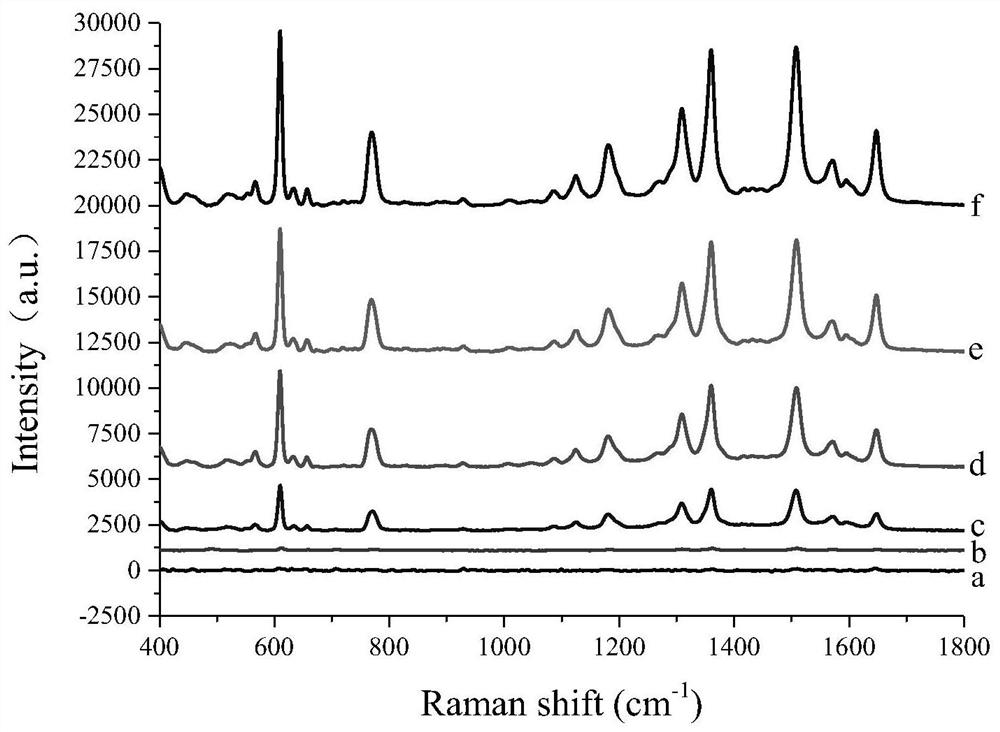

[0033] (2) Preparation of highly efficient SERS materials with magnetic self-flocculation: take the above magnetic Fe 3 o 4Add deionized water to the particles, then add 0.03g polyethyleneimine to mix, ultrasonically disperse evenly, then add 10mL of 70 mM silver ...

Embodiment 2

[0042] This embodiment provides another material with magnetic self-flocculation efficient extraction and recovery and SERS enhancement properties and its preparation method, including the following steps:

[0043] (1) Preparation of magnetic Fe 3 o 4 Particles: Dissolve 1.0g of ferrous sulfate heptahydrate and 0.3g of citric acid in 10mL of deionized water, stir evenly and pour into the lined polytetrafluoroethylene, then add 10mL of 45% hydrazine hydrate, then put into the reaction kettle Put it in a constant temperature drying oven at 160 °C for 7 h, collect the black precipitate with a magnet after cooling, and wash it repeatedly for 3-5 times to obtain the magnetic Fe 3 o 4 particles.

[0044] (2) Preparation of highly efficient SERS materials with magnetic self-flocculation: take the above magnetic Fe 3 o 4 Add deionized water to the particles, then add 0.02 g polyethyleneimine to mix, ultrasonically disperse evenly, then add 10 mL of 65 mM silver nitrate solution a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com