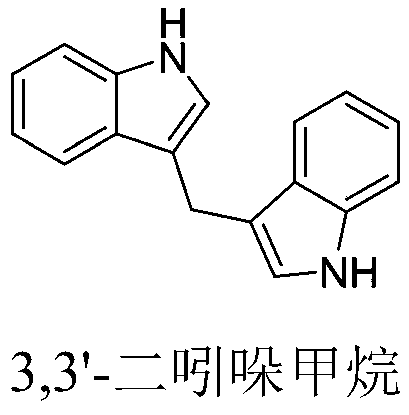

Method for synthesizing 3,3'-diindolylmethane

A technology of diindolylmethane and a synthesis method, which is applied in the field of synthesis technology of 3,3'-diindolylmethane, can solve the problems of poor catalytic performance, not easy to be environmentally friendly, complicated to operate, etc., and achieves reduction of energy consumption and material loss , saving reaction time and improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

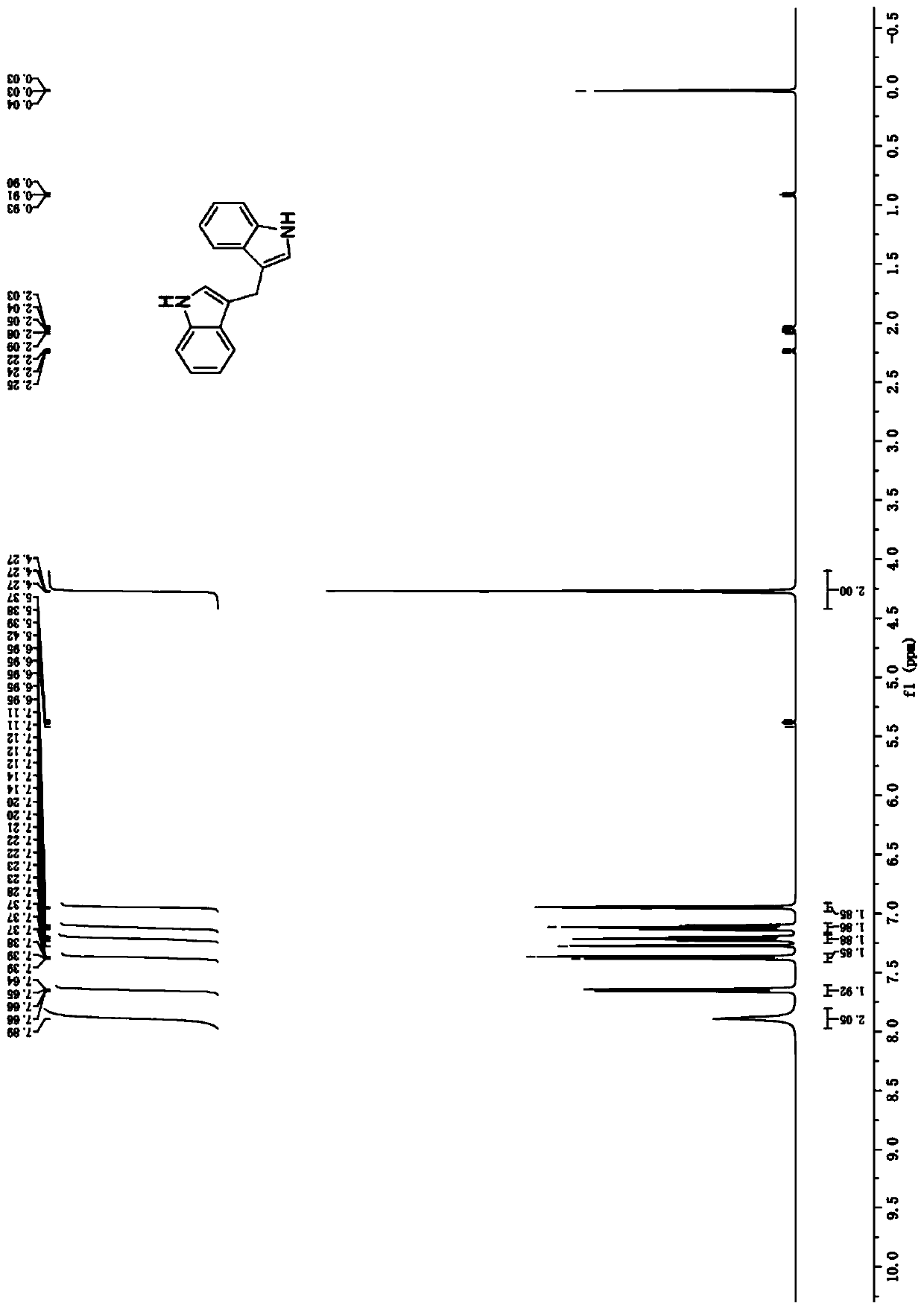

[0019] Example 1: Add 280 grams of water, 120 grams of ethanol, 100.0 grams of indole, 15.4 grams of paraformaldehyde, and 7.4 grams of p-toluenesulfonic acid into a 1L three-necked flask, and react at 40-50° C. for 3 hours. TLC detects that the reaction is basically Stop stirring when complete, filter, wash with ethanol to obtain crude 3,3'-diindolylmethane, use toluene as solvent for crude product, recrystallize by heating, after cooling and precipitation is complete, filter its crystals, and dry in vacuum at low temperature to obtain a white solid 98.2 g, 93.4% yield, >99.0% purity. 1H NMR (500MHz, CDCl3): δ7.89(s, 2H), δ7.65(d, J=8.2Hz, 2H), δ7.38(d, J=8.2Hz, 2H), δ7.22(t , J=7.6Hz, 2H), δ7.12(t, J=7.6Hz, 2H), δ6.95(s, 2H), δ4.27(s, 2H).

Embodiment 2

[0020] Example 2: Add 280 grams of water, 120 grams of ethanol, 100.0 grams of indole, 15.4 grams of paraformaldehyde, and 14.7 grams of p-toluenesulfonic acid into a 1L three-necked flask, and react at 40-50°C for 3 hours. TLC detects that the reaction is basically Stop stirring when complete, filter, wash with ethanol to obtain crude 3,3'-diindolylmethane, use toluene as solvent for crude product, recrystallize by heating, after cooling and precipitation is complete, filter its crystals, and dry in vacuum at low temperature to obtain a white solid 99.0 g, yield 94.1%.

Embodiment 3

[0021] Example 3: Add 250 grams of water, 120 grams of ethanol, 100.0 grams of indole, 51.3 grams of 37% formaldehyde solution, and 7.4 grams of p-toluenesulfonic acid into a 1L three-necked flask, and react at 40-50° C. for 3 hours, and detect the reaction by TLC After it is almost complete, stop stirring, filter, and wash with ethanol to obtain the crude product of 3,3'-diindolylmethane. The crude product uses toluene as a solvent, and recrystallizes by heating. Solid 84.1 g, yield 80.0%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap