Method for synthesizing 1,1,1,3,5,5,5-heptamethyl trisiloxane by utilizing hydrogen containing silicone oil low-boiling-point substance

A technology of heptamethyltrisiloxane and hexamethyldisiloxane, which is applied in the field of organosilicon compound synthesis, can solve the problems of complex components of low boilers, high purification costs, and low product yields, reaching dangerous The effect of reduction and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

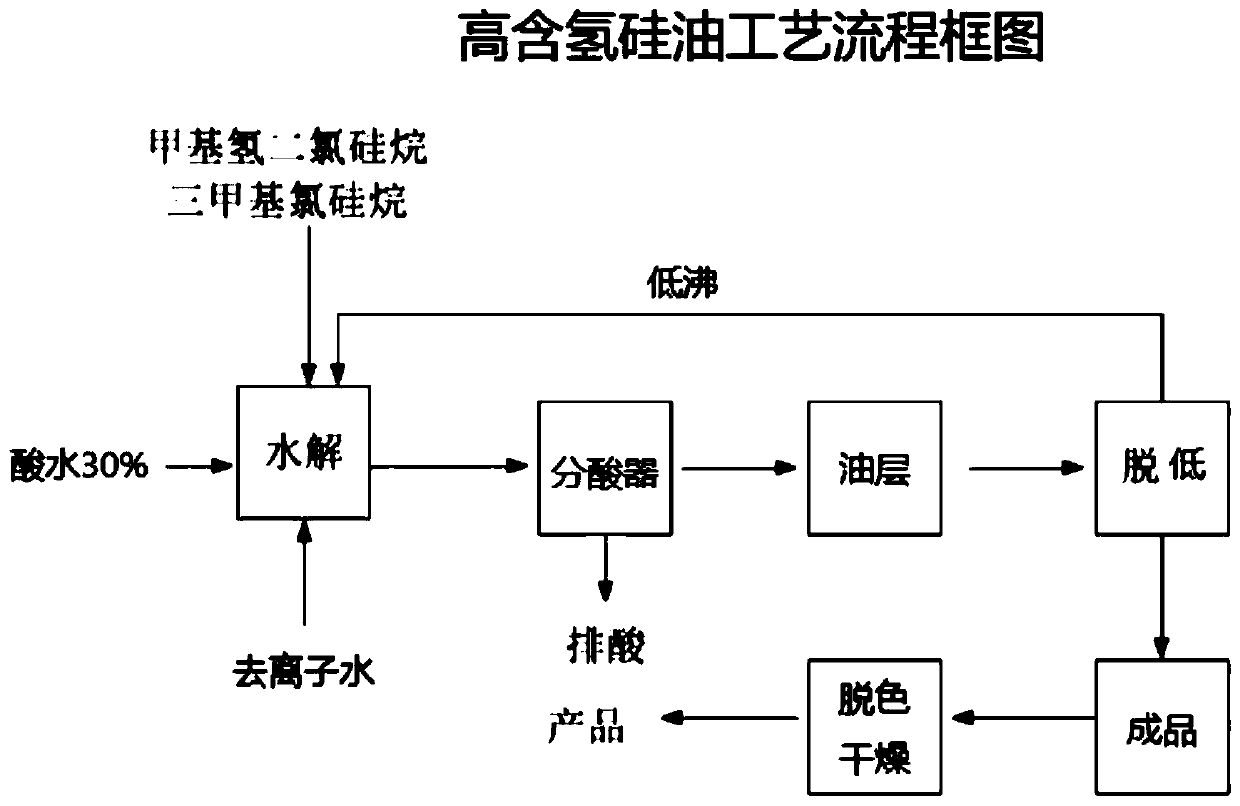

Method used

Image

Examples

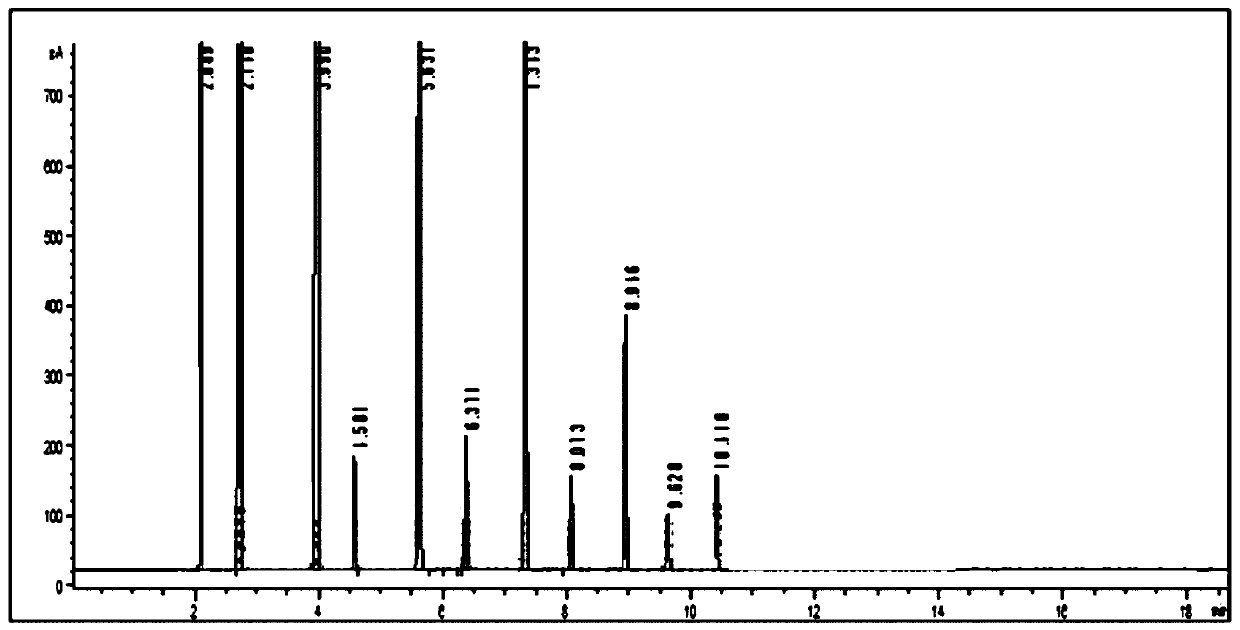

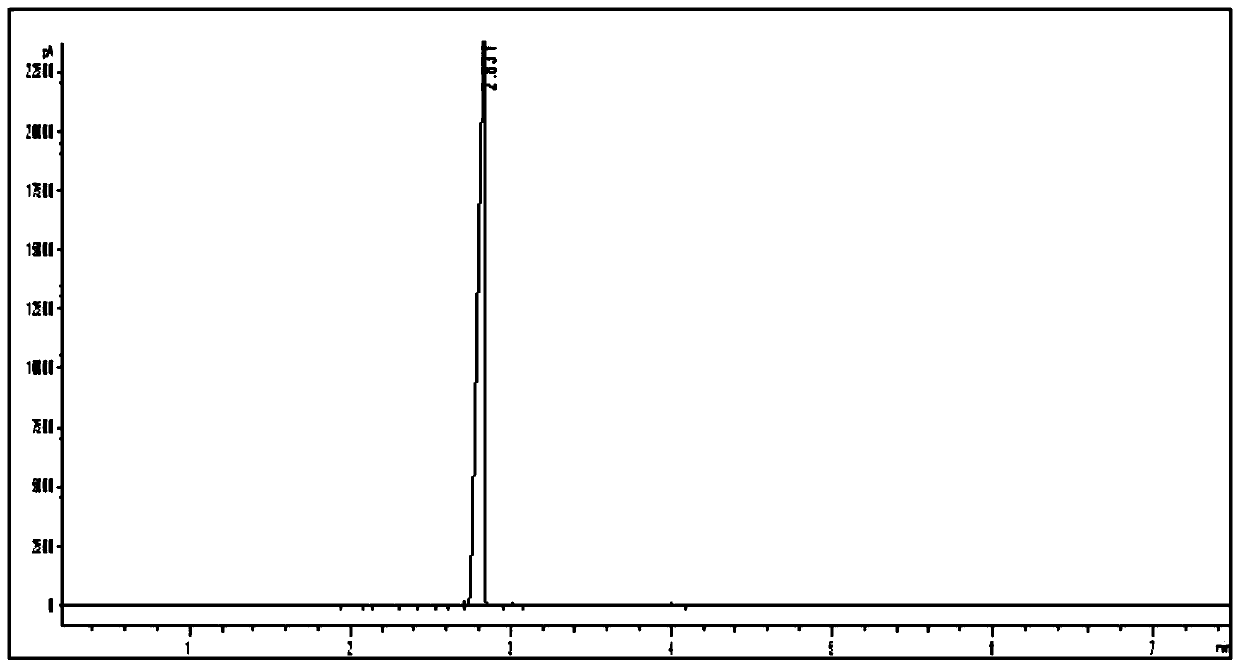

Embodiment 1

[0045] Feed hexamethyldisiloxane, hydrogen-containing silicone oil low boilers, and acid clay catalyst at a mass ratio of 10:1:0.05, the total amount of feed is 300g, and add them to the reactor equipped with mechanical stirring, thermometer and reflux condenser , heat up under stirring, control the temperature at 65°C for 8 hours, then cool down and filter to obtain a synthetic solution containing 1,1,1,3,5,5,5-heptamethyltrisiloxane, after analysis 1,1, The content of 1,3,5,5,5-heptamethyltrisiloxane was 21.5%. The synthesis liquid is rectified by atmospheric pressure, the top temperature is controlled at 99-101°C to steam out MM, and then the temperature is lowered to below 50°C, the vacuum pump is started (the pressure is -0.095MPa), and the transition is evaporated between 65-70°C Fraction, 58.05g of 1,1,1,3,5,5,5-heptamethyltrisiloxane product with a content greater than 99% was distilled at 76-79°C (accounting for 1,1,1, 90% of the total amount of 3,5,5,5-heptamethyltr...

Embodiment 2

[0049] Feed hexamethyldisiloxane, hydrogen-containing silicone oil low boilers, and acid clay catalyst at a mass ratio of 8:1:0.05, with a total amount of 300 g, and add them to a reactor equipped with mechanical stirring, a thermometer, and a reflux condenser , heat up under stirring, control the temperature at 65°C for 8 hours, then cool down and filter to obtain a synthetic solution containing 1,1,1,3,5,5,5-heptamethyltrisiloxane, after analysis 1,1, The content of 1,3,5,5,5-heptamethyltrisiloxane was 23.2%.

[0050] According to the method of Example 1, atmospheric distillation and vacuum distillation were performed on the synthesis liquid to obtain a 1,1,1,3,5,5,5-heptamethyltrisiloxane product with a content greater than 99%. The amount of 1,1,1,3,5,5,5-heptamethyltrisiloxane in the obtained transition fraction accounts for 1,1,1,3,5,5,5-heptamethyltrisiloxane in the synthetic liquid About 10% of the total amount of trisiloxane. The high-boiling mixture after vacuum di...

Embodiment 3

[0052] Feed hexamethyldisiloxane, hydrogen-containing silicone oil low boilers, and acid clay catalyst at a mass ratio of 6:1:0.05, with a total amount of 300 g, and add them to a reactor equipped with mechanical stirring, a thermometer, and a reflux condenser , heat up under stirring, control the temperature at 65°C for 8 hours, then cool down and filter to obtain a synthetic solution containing 1,1,1,3,5,5,5-heptamethyltrisiloxane, after analysis 1,1, The content of 1,3,5,5,5-heptamethyltrisiloxane was 26%.

[0053] According to the method of Example 1, atmospheric distillation and vacuum distillation were performed on the synthesis liquid to obtain a 1,1,1,3,5,5,5-heptamethyltrisiloxane product with a content greater than 99%. The amount of 1,1,1,3,5,5,5-heptamethyltrisiloxane in the obtained transition fraction accounts for 1,1,1,3,5,5,5-heptamethyltrisiloxane in the synthetic liquid About 10% of the total amount of trisiloxane. The high-boiling mixture after vacuum dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com