Drilling and solidifying integrated working fluid for improving two-interface cementation quality, and application method thereof

A technology of working fluid and interface glue, which is applied in the direction of chemical instruments and methods, earthwork drilling, drilling composition, etc., can solve the problems of poor compatibility, deterioration of drilling fluid performance, and increase of drilling fluid viscosity, etc., to reduce The possibility of mutual channeling, beneficial to protection and discovery, and the effect of improving cementing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

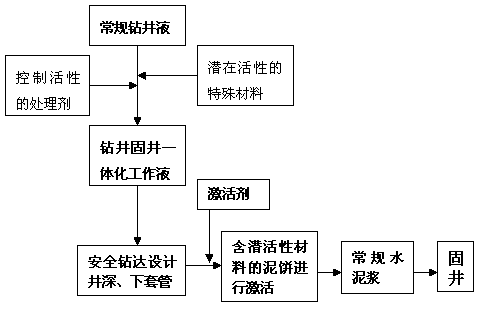

Method used

Image

Examples

Embodiment 1

[0041] The condition of the latent active material of embodiment 1 drill-solid integrated working fluid

[0042] The following conditions must be met for the selection of high-strength composite latent active cementitious materials that meet the drilling-solid integrated working fluid:

[0043] 1. The activity of materials is potential. Various mineral compositions are in a metastable state under a certain environment (normal temperature and pressure). Mineral active materials do not have a separate hydration ability, and all require specific media conditions (water, climate, thermal effects, Chemical substances, etc.) to stimulate its potential activity.

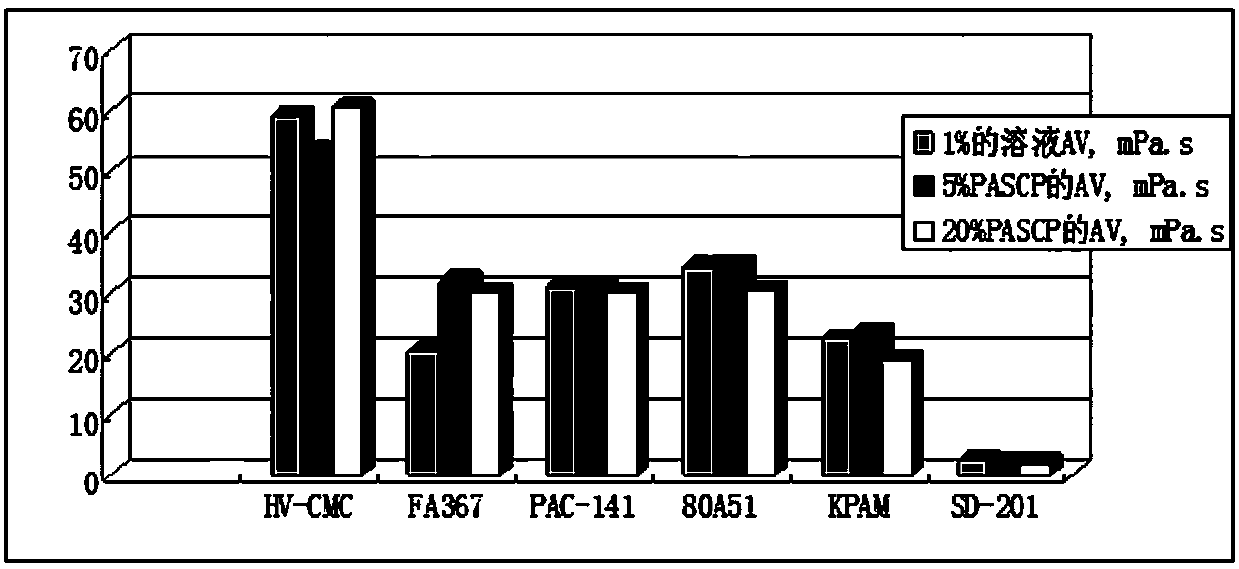

[0044] 2. Good compatibility with drilling fluid, no gelation, little impact on drilling fluid loss, no serious damage to drilling fluid performance, meeting the requirements of long-term drilling fluid circulation, no activation and solidification after long-term rolling at 150°C, no loss active.

[0045] 3. The activity...

Embodiment 2

[0054] Example 2 Potentially active material in drilling-solid integration PH control

[0055] Drilling fluid: Measure 500mL of 4% mud in the room, use Na 2 CO 3 , NaOH and HCL to the specified pH value, add 35% (accounting for the percentage of the mass of the soil slurry) active material under high-speed stirrer (1000r / min) stirring, and stop at least twice during the period to scrape off the phosphate attached to the container. For gelled material on the wall, shear force values of the active material in bentonite slurries of different pH values were determined. Experiments show that when the pH is in the range of 1 to 6, the mixed solution will flocculate to a certain extent, and the soil particles will coalesce; the shear force will change to a certain extent, and the shear force will not change much with the extension of time, and there will be no gelation and solidification after stirring . The performance of the slurry is stable within the pH range of 6 to 12.5,...

Embodiment 3

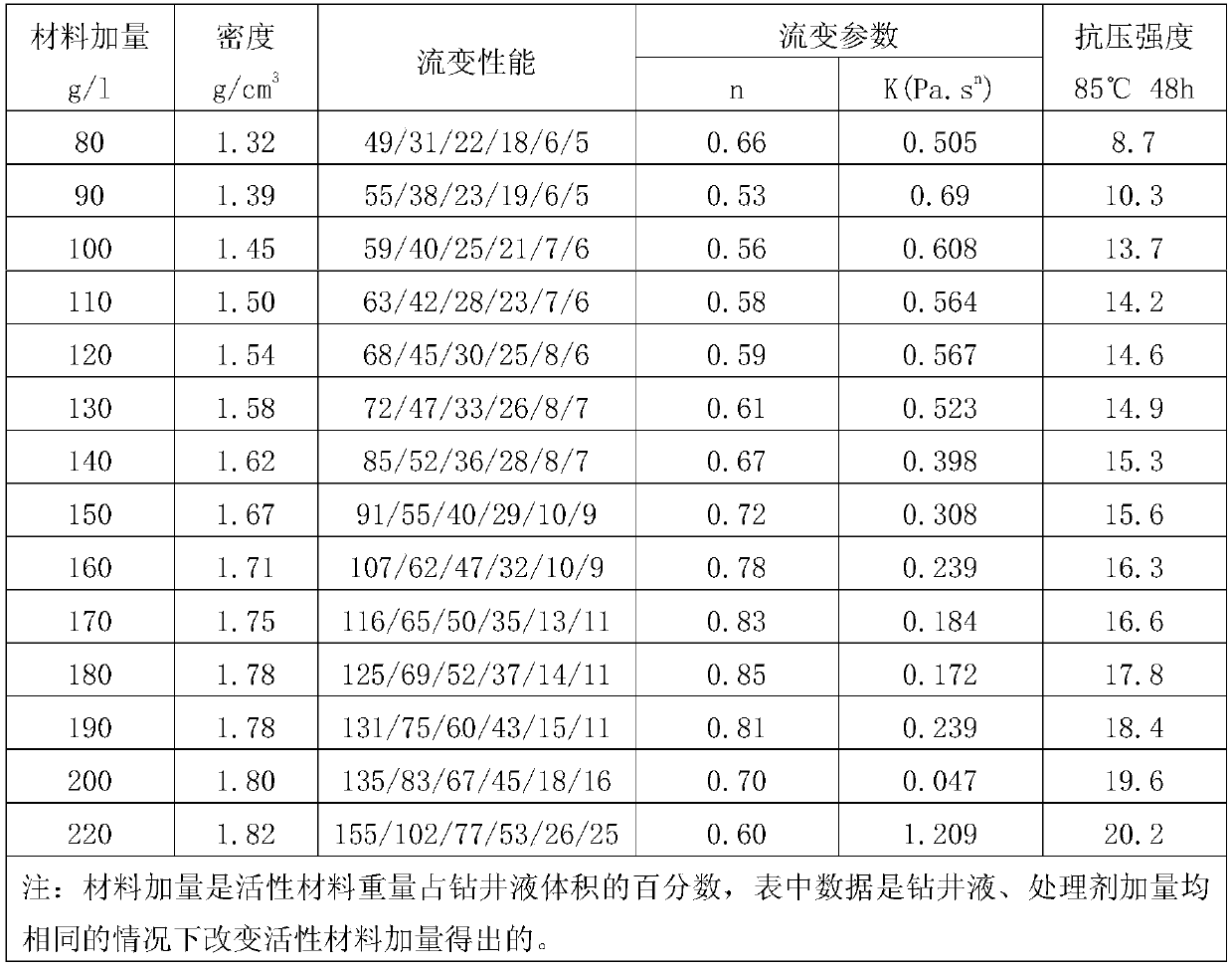

[0057] Embodiment 3 Curing evaluation under high temperature and high pressure containing latent active material

[0058] In order to evaluate the viscosity change of the working fluid under high temperature and high pressure, the high temperature and high pressure thickening instrument is used indoors to simulate the environment of 150°C / 60MPa and 170°C / 80MPa to conduct thickening experiments on the working fluid containing 5-25% latent active materials. The experimental results show that the working fluid containing latent active materials still maintains good rheological properties under high temperature and pressure conditions of 150°C / 60Mpa and 170°C / 80Mpa, and there is no solidification of the working fluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com