Full-automatic steel ladle argon connecting device

A fully automatic, ladle technology, which is applied in the direction of casting molten material containers, manufacturing tools, metal processing equipment, etc., can solve the problems of low connection success rate, short operation time, heavy maintenance workload, etc., to reduce the movement resistance of the cylinder, and quickly Easy replacement and installation, maintenance and inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

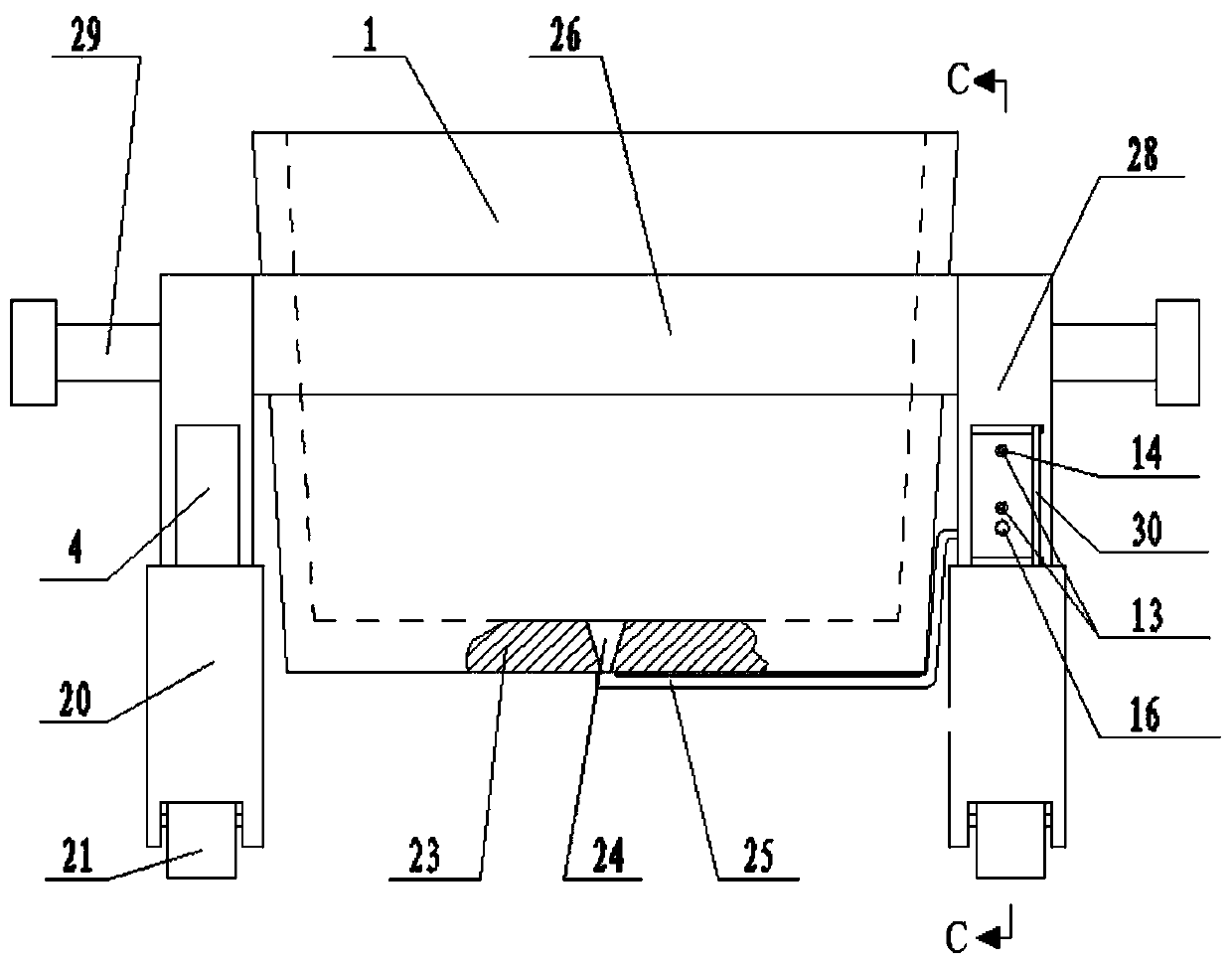

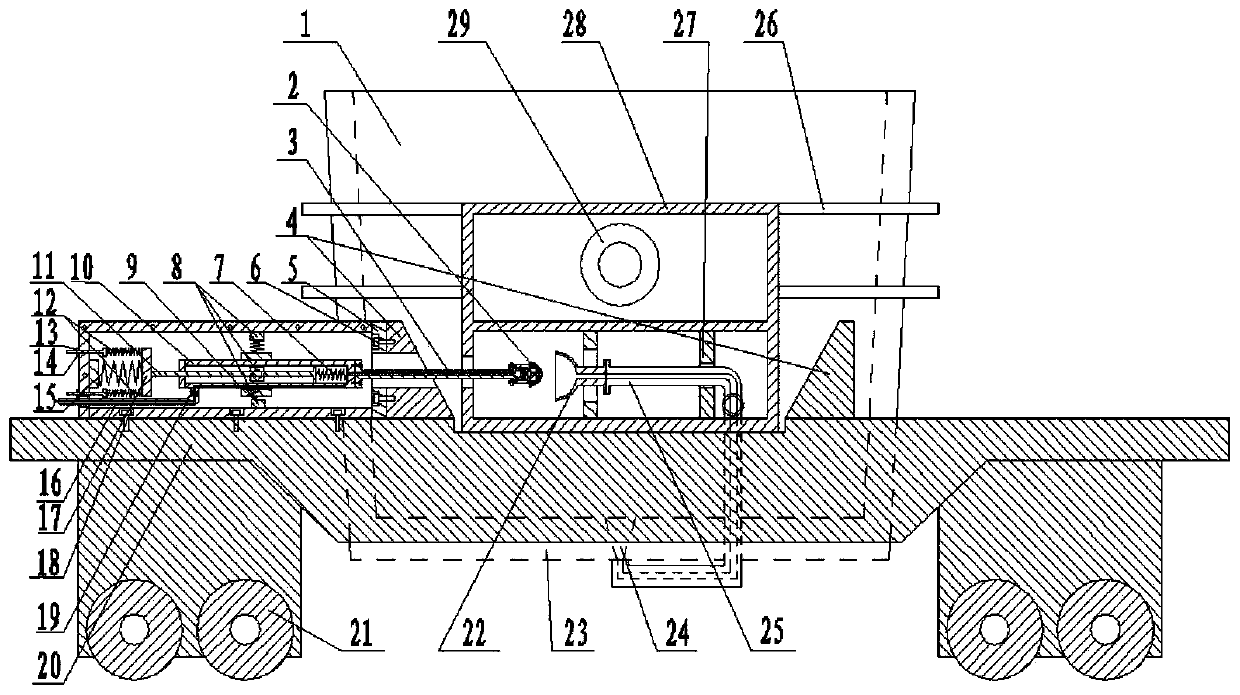

[0032] Such as figure 1 and figure 2 A fully automatic argon receiving device for a ladle is shown, comprising a ladle car, a ladle 1, and a horizontal follow-up argon receiving system, two opposite guide plates 4 are provided on both sides of the ladle car; the ladle 1 passes through The saddles 28 on both sides are installed on the ladle car, and the saddle 28 is located between the two guide plates 4 on the same side; the horizontal follow-up argon connection system is installed on one side of the guide plate 4 of the ladle car Above, the gas outlet end of the horizontal follow-up argon connection system communicates with the injection hole 24 provided at the inner bottom of the ladle 1 through a pipeline.

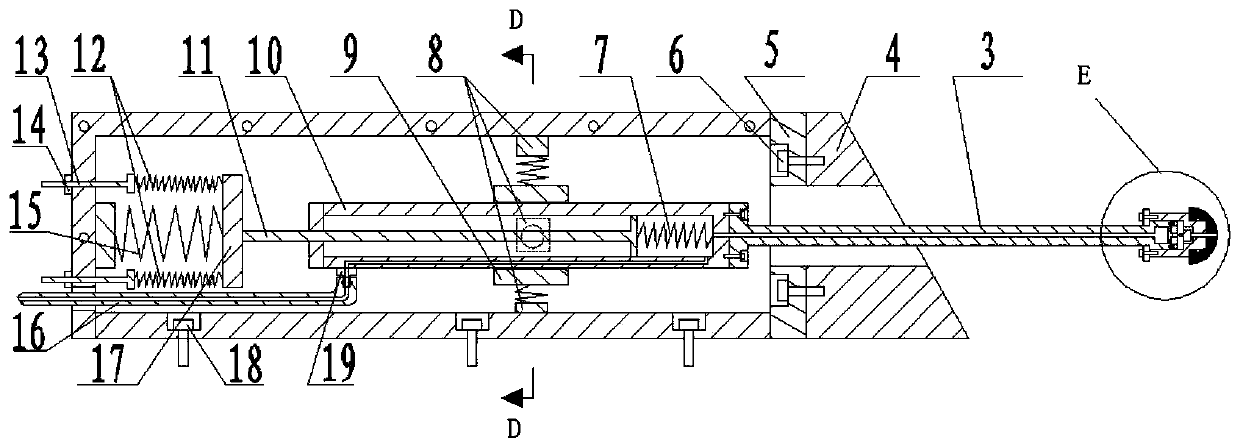

[0033] Preferably, as image 3 As shown, the horizontal follow-up argon connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com