Real-time monitoring method and device for laser cladding

A real-time monitoring and laser cladding technology, applied in measurement devices, metal material coating processes, instruments, etc., can solve the problems of waste of resources, fluctuations in cladding quality, and low measurement accuracy, and achieve the goal of improving work efficiency and quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

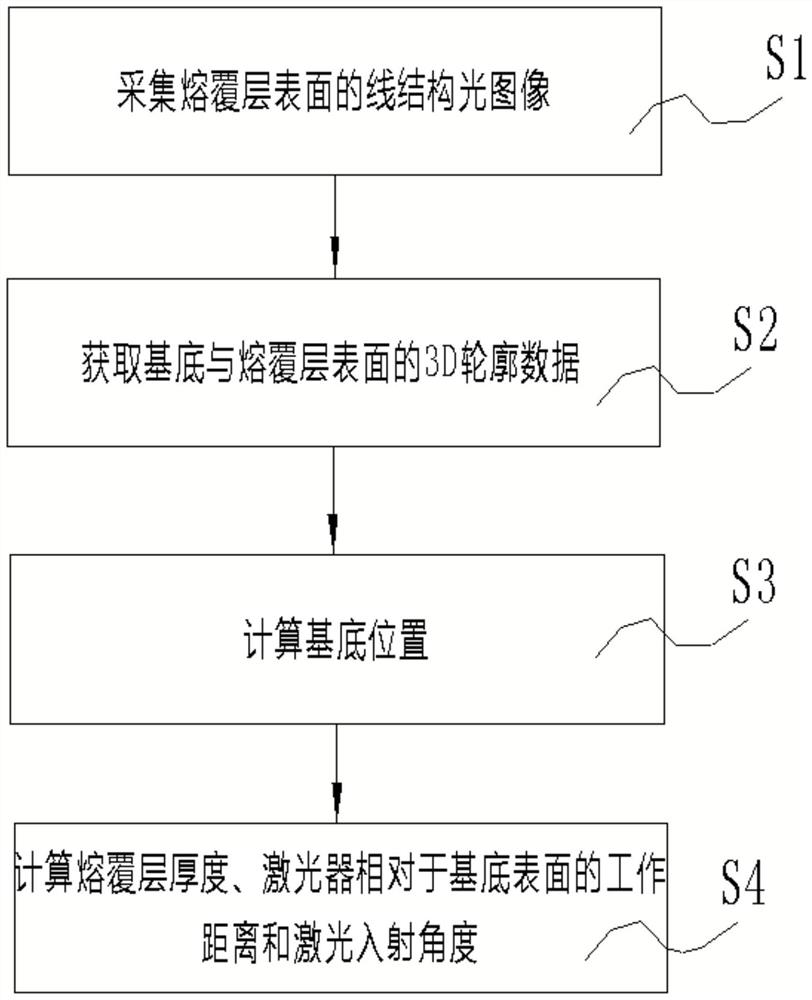

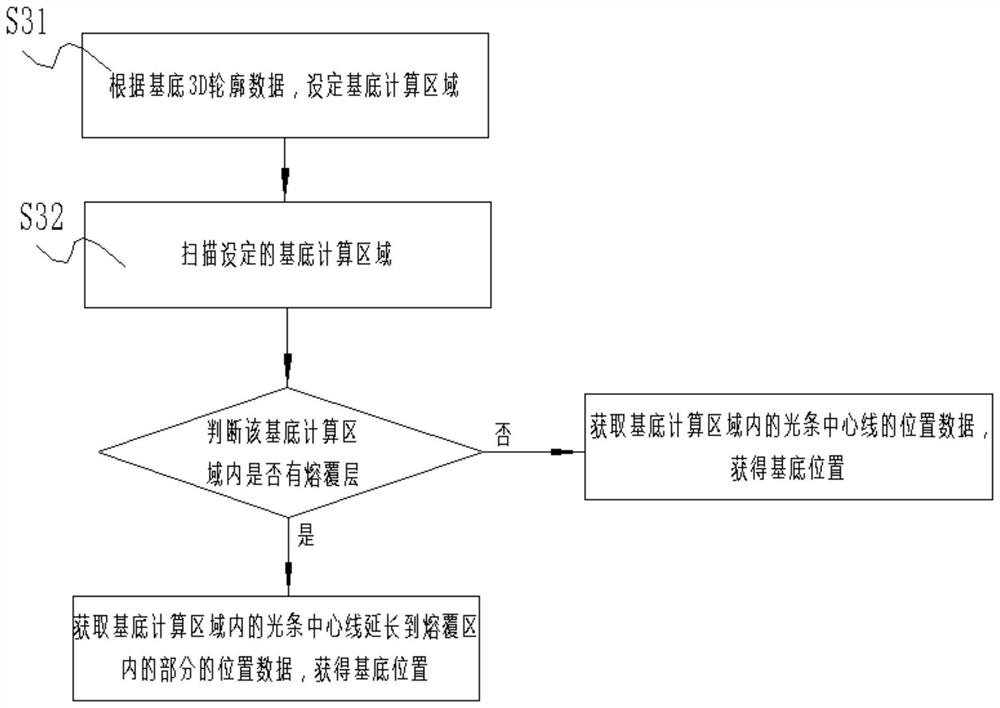

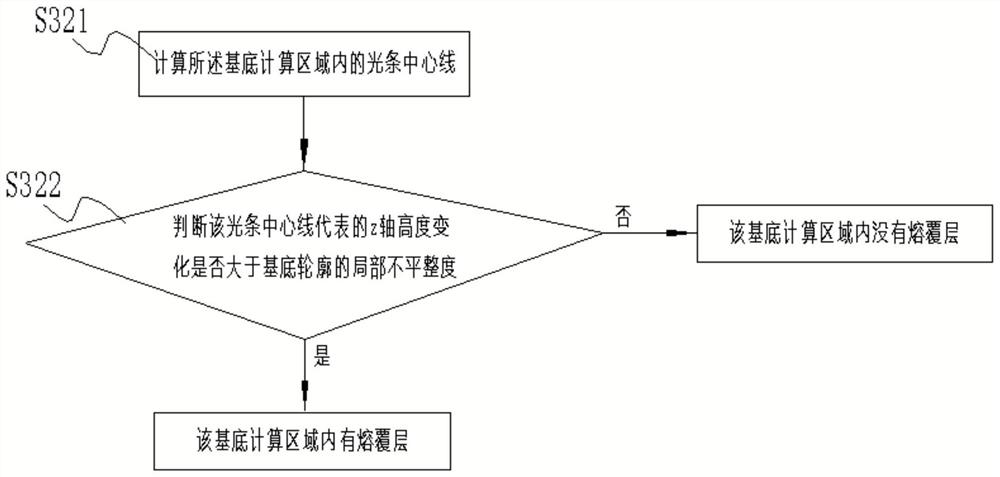

[0063] Such as Figure 1-Figure 7 As shown, a real-time monitoring method for laser cladding, including the following steps:

[0064] A real-time monitoring method for laser cladding, comprising the steps of:

[0065] S1. Collecting a line structured light image on the surface of the cladding layer. An alternative solution is to project the measurement laser of the laser profiler onto the surface of the substrate and cladding layer based on the triangulation principle of line structured light. The laser profiler is fixedly installed relative to the cladding laser, and the measuring laser emitted by the laser profiler is aimed at the cladding area near the cladding laser spot before starting the cladding. If the cladding laser spot is close to a rectangular shape, a more preferred installation position is to make the laser line of the laser profiler parallel to the long axis of the cladding laser spot, 10-25mm away from the center of the cladding area, and try to make the Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com