Submarine pipeline landing section spaced soil body liquefaction resistance lifting device and method

A technology for submarine pipelines and landing sections, which is applied to the field of spaced soil anti-liquefaction capacity improvement devices for submarine pipeline landing sections. The effect of improving soil compactness and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

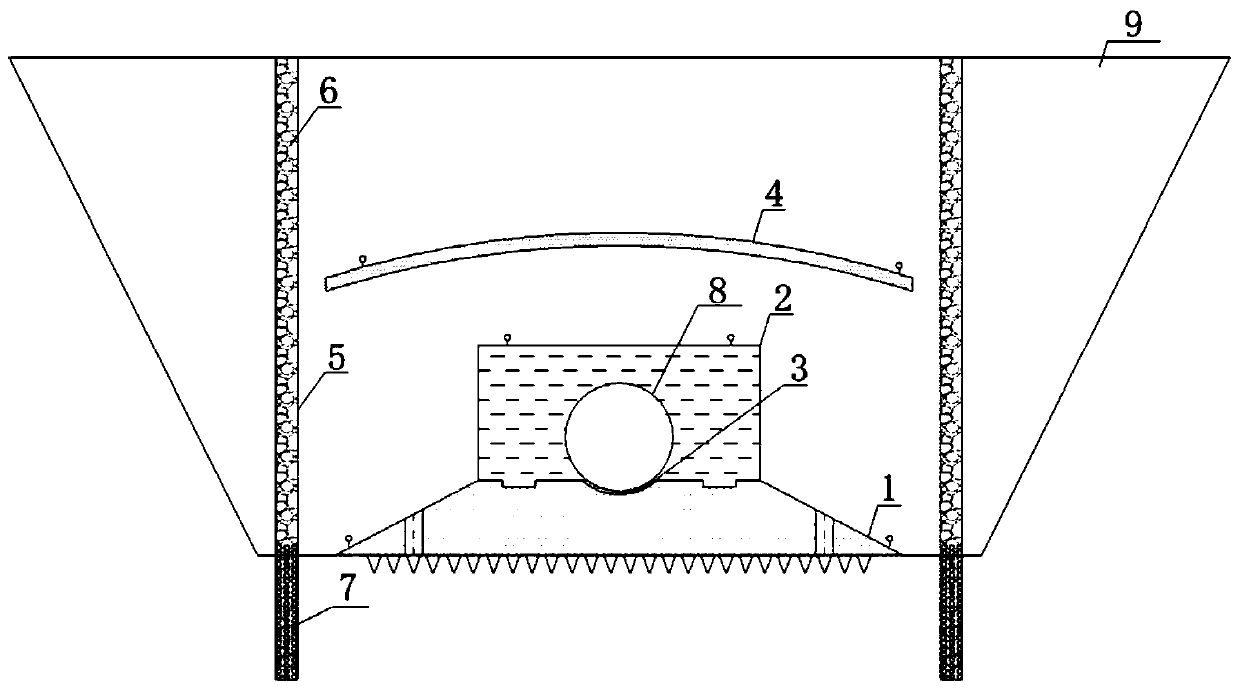

[0022] A device for improving the anti-liquefaction capacity of the subsea pipeline at intervals in the landing section, such as figure 1 As shown, it includes: covering base 1, temporary upper covering body 2, rubber cushion 3, arc-shaped concrete slab 4, drainage casing 5, backfilling gravel 6, screen hole 7, submarine pipeline 8, pipe trench 9, etc.

[0023] in:

[0024] The covering base 1 and the temporary upper covering body 2 form the soil covering unit of the landing section of the submarine pipeline, which is responsible for covering and compacting the semi-disturbed seabed on the central route of the submarine pipeline, and providing installation grooves for the 8 channels of the submarine pipeline .

[0025] specifically,

[0026] 1) Several cones are prefabricated at the bottom of the covering base 1, which are used to embed the seabed, and cover and compact the semi-disturbed seabed due to excavation; the sides of the covering base 1 are prefabricated soil The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com