Method for realizing water plugging of immovable string of high-water-cut oil well

A technology for oil wells and moving pipes, which is applied to the field of water plugging by immovable pipe strings in high water-cut oil wells, can solve problems such as high maintenance costs, high operating costs, and difficulty in injecting into target layers, and achieves low maintenance costs and low operating costs in the later stage. , the effect of affecting a large space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

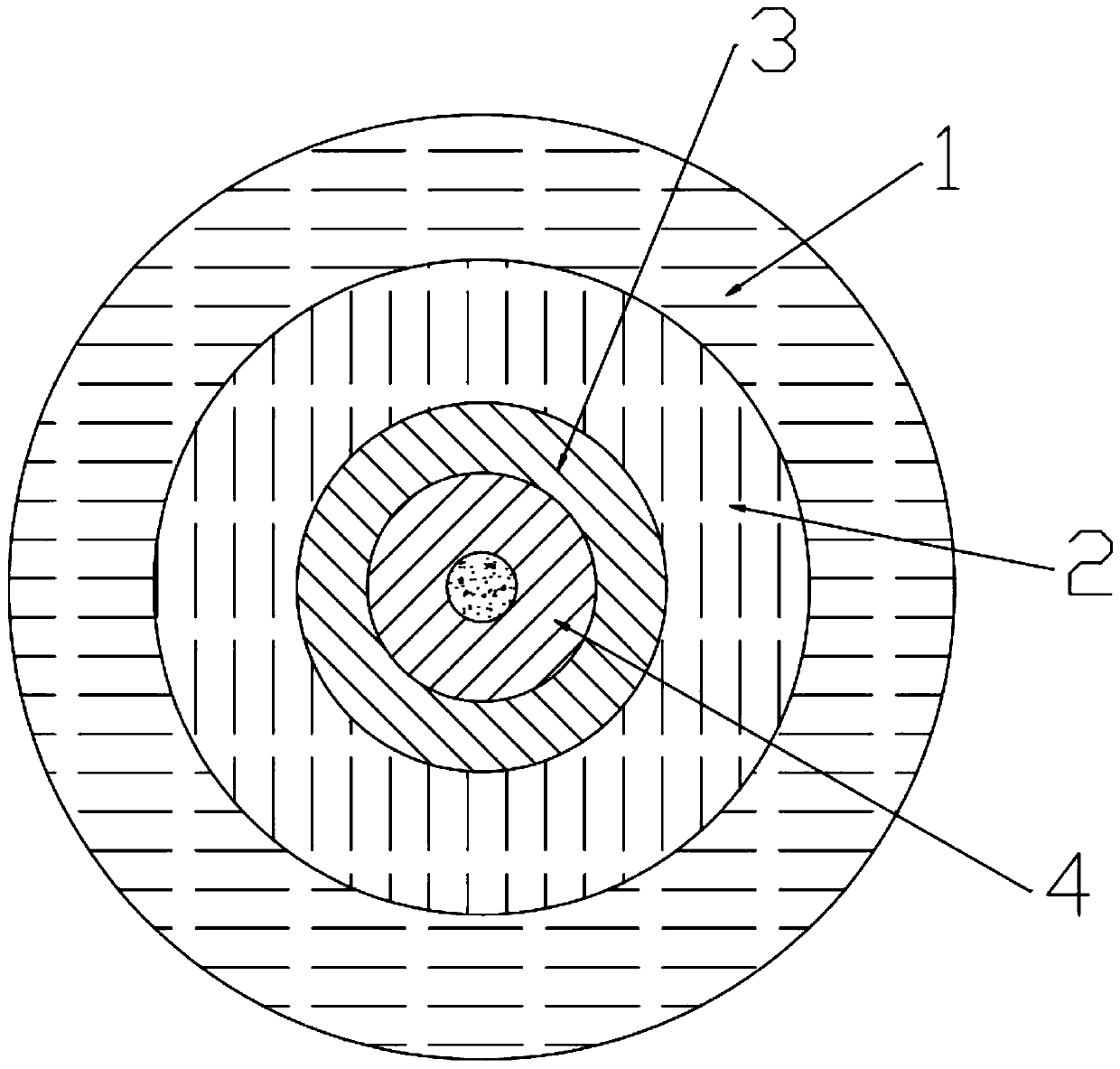

[0015] A method for realizing water shutoff without moving a string in a high water-cut oil well according to the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0016] combined with figure 1 A method for realizing water plugging without moving a string in a high water-cut oil well, comprising the following steps:

[0017] (1) For the first slug, different concentrations are injected into the oil layer at a constant flow rate, and the injection pressure is 2-10 MPa; small test, firstly, the matching test of equipment, process, oil well and reservoir parameters from low to high concentration is used to test the feasibility of the follow-up plan and Provide a basis for improvement.

[0018] (2) The second slug, the front slug, injects into the deep part of the oil layer, the injection pressure is 2-4MPa, the second slug is located inside the first slug; it is a selective front slug that controls water and reduces oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com