Ammonium hydroxide heat exchanger

A heat exchanger and ammonia water technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as affecting the thermal efficiency of ammonia water power cycle and complex structure of ammonia water power cycle, and achieve the effect of promoting mutual migration and increasing diffusion speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

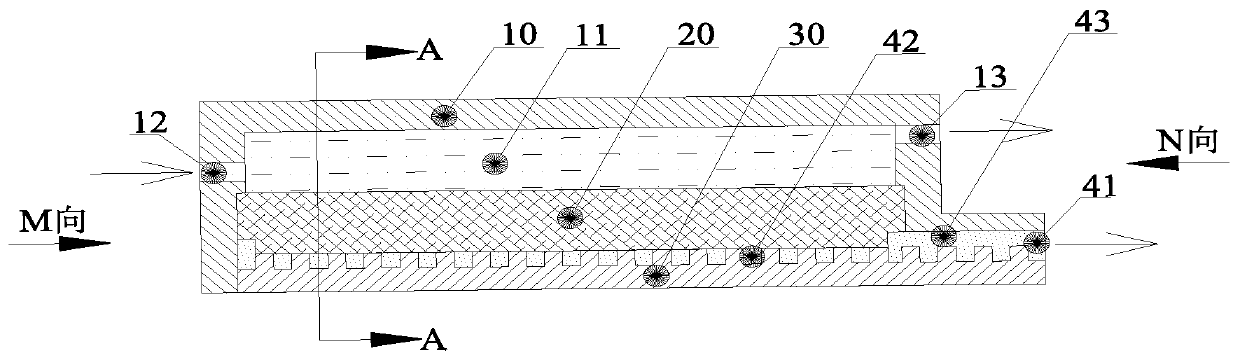

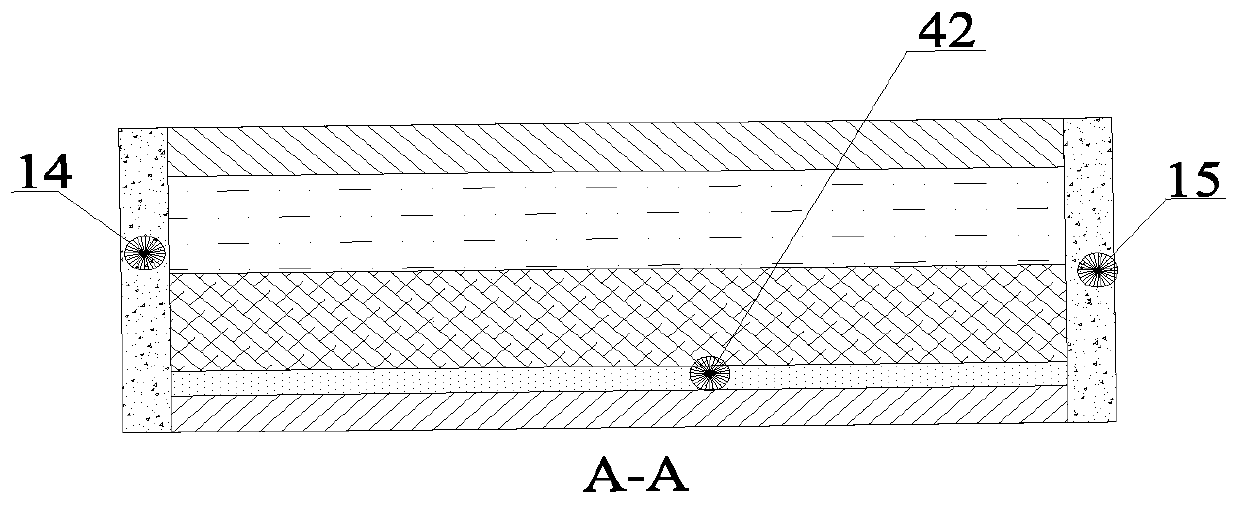

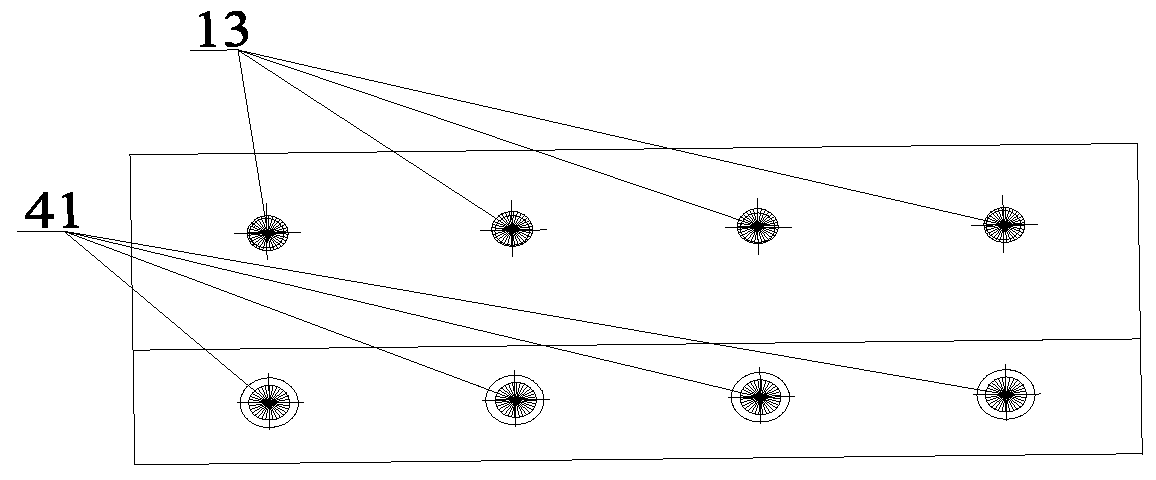

[0027] Such as Figure 1-4 As shown, the present embodiment provides an ammonia water heat exchanger, including a housing 10 and a capillary core 20; the inside of the housing 10 is a cuboid or approximately cuboid cavity, and the bottom wall of the housing 10 is a heat exchange Wall surface 30, the capillary core 20 is horizontally arranged on the heat exchange wall surface 30 in the housing 10 and its lower end is attached to the upper end of the heat exchange wall surface 30, and the edge of the capillary core 20 is in contact with the heat exchange wall surface 30. The inner side walls of the housing 10 are connected to form a liquid storage chamber 11 for storing ammonia, and the left and right side walls of the housing 10 are respectively provided with an ammonia water inlet 12 and an ammonia water outlet 13 communicating with the liquid storage chamber 11, On the side where the lower end of the capillary wick 20 is bonded to the heat exchange wall 30, a channel for rich...

Embodiment 2

[0037] The ammonia water heat exchanger can be directly attached to the heat source of the heating equipment, or a heat source fluid channel 51 can be set on the ammonia water heat exchanger to superheat the ammonia-rich vapor, such as Figure 5-6As shown, different from Embodiment 1, the ammonia water heat exchanger also includes a lower shell 50, the lower shell 50 is hollow inside and has an upper end opening, and the upper end opening of the lower shell 50 is in contact with the heat exchanger. The lower end of the heat wall surface 30 is connected so that the inside of the lower casing 50 forms a heat source fluid passage 51, and the left and right ends of the lower casing 50 are respectively provided with a heat source fluid inlet 52 and a heat source fluid inlet 52 communicating with the heat source fluid passage 51. Heat source fluid outlet 53 . The heat source fluid flows directly in the heat source fluid channel 51 to superheat the ammonia-rich vapor. Wherein, the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com