Induction heating distributed control system

A distributed control and induction heating technology, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of easy information transmission conflicts and collisions, large data collection, low transmission efficiency, etc., and achieve convenient management. , high precision, simple program effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0114] 1. Analysis and design of distributed control of induction heating power supply.

[0115] (1) System model of distributed control of induction heating power supply.

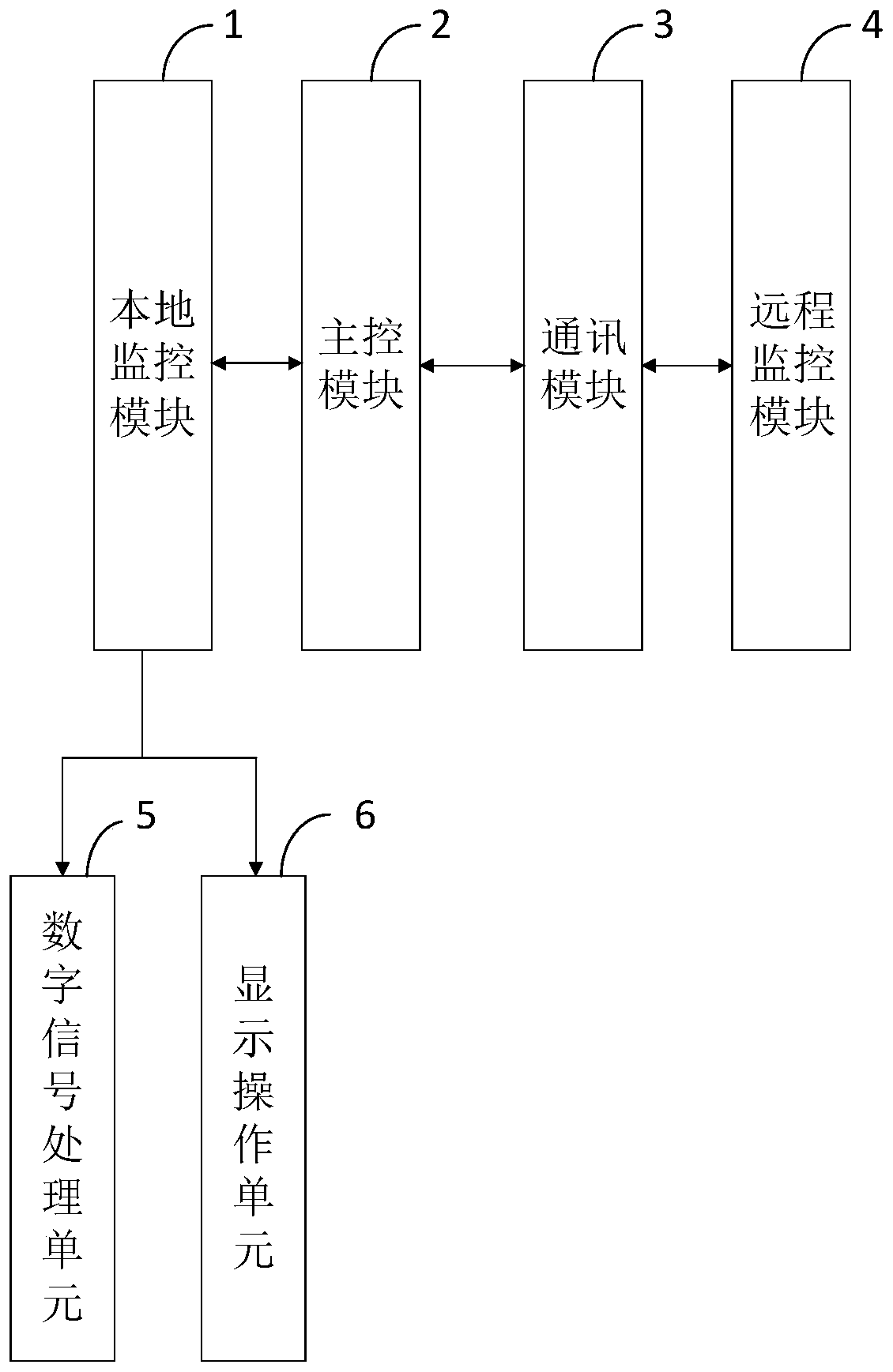

[0116] Such as figure 2 As shown, the structure of the induction heating power supply distributed control system mainly includes two parts: the local operation unit, that is, an industrial Diwen touch screen, which is mainly responsible for the induction heating power supply status (running, stopping, fault) and current and frequency setting Display and modification of values. In addition, the local DSP is the core of the slave control system, which mainly processes real-time data from the master control system, collects various parameters of the induction heating power supply, and transmits them to the master control system and DWIN touch screen in real time.

[0117] The remote control unit, the upper computer remotely displays and modifies the status, parameters and communication status of each induc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com