Ultrathin lithium-silver alloy strip for lithium ion battery anode and preparation method thereof

A lithium-ion battery, ultra-thin technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as difficulty in preparing ultra-thin lithium strips, adhesion, etc., achieve excellent ductility, uniform thickness, and reduce damage rates Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of the ultra-thin lithium-silver alloy ribbon for lithium-ion battery negative electrode provided by the invention comprises the following steps:

[0043] Step 1, in a first predetermined environment, heating the lithium to a predetermined temperature, so that the lithium is completely melted into liquid lithium;

[0044] Step 2, in the first predetermined environment and at a predetermined temperature, add silver to the liquid lithium according to a predetermined mass ratio, stir for a predetermined time, the silver is liquefied, and completely mixed with the liquid lithium to form a lithium-silver solid solution;

[0045] Step 3, heating is stopped, and the lithium-silver solid solution is cooled to room temperature in the first predetermined environment to obtain a solid lithium-silver solid solution block;

[0046] Step 4, in the second predetermined environment, put the lithium-silver solid solution block into a roller press and roll it to a pr...

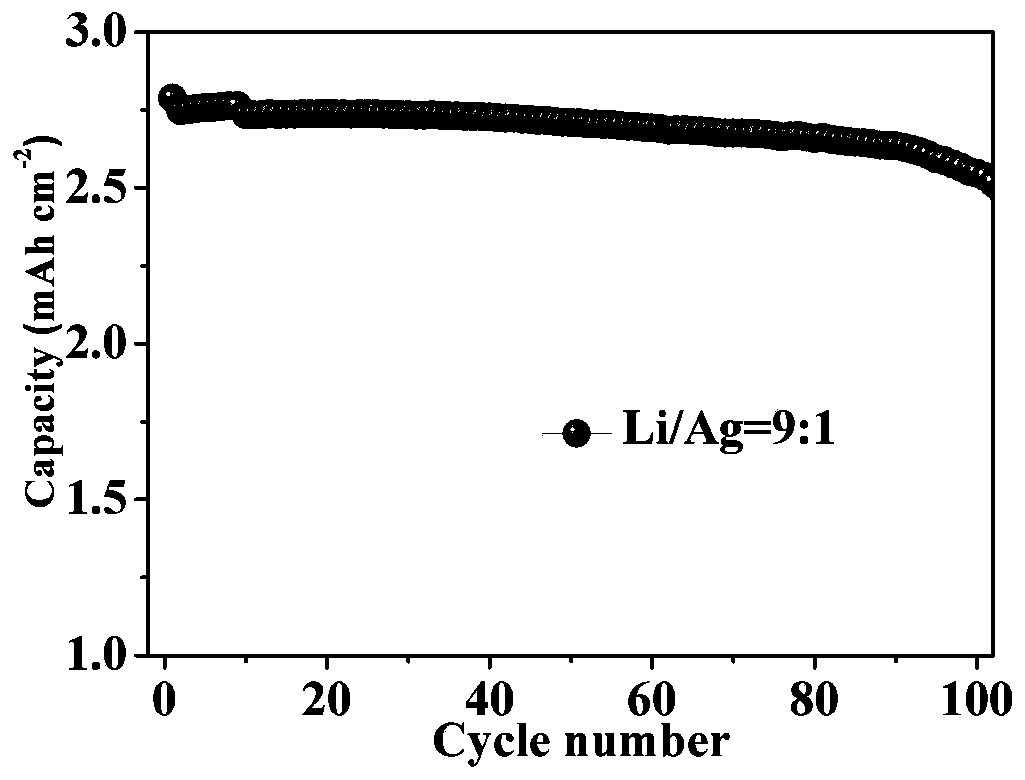

Embodiment 1

[0058] The raw materials with a mass ratio of lithium to silver of 9:1 were put together, heated until completely melted, stirred evenly, and a 45 μm lithium-silver alloy ribbon was prepared. Use this lithium-silver alloy strip as the negative electrode, and use a standard capacity density of 3mAh cm -2 The lithium iron phosphate is used as the positive electrode, and the full battery LFP / / 9Li1Ag is assembled. After the assembled full battery LFP / / 9Li1Ag was placed for 4 hours, a constant current charge and discharge test was carried out with battery testing equipment, and the results are shown in figure 1 .

[0059] figure 1 It is a schematic diagram of the battery cycle results in Example 1 of the present invention.

[0060] Such as figure 1 As shown, the abscissa indicates the number of cycles of the full battery, and the ordinate indicates the discharge capacity density of the full battery. From figure 1 It can be seen that the first discharge capacity density of the...

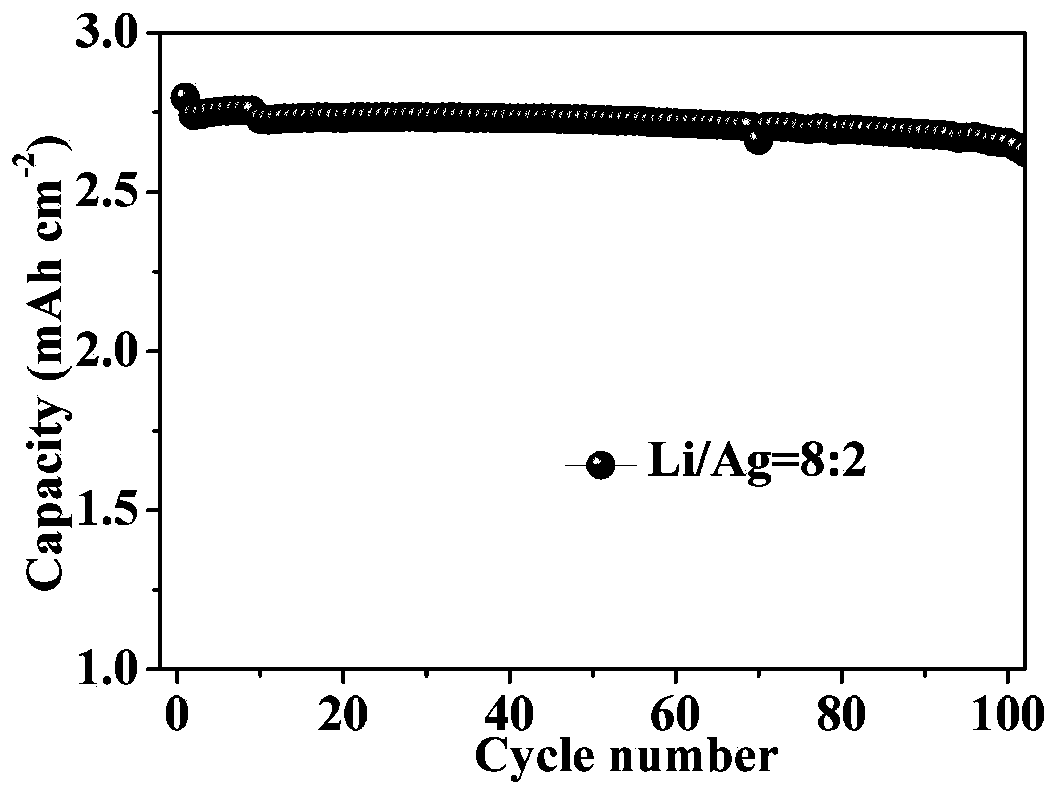

Embodiment 2

[0062] The raw materials with a mass ratio of lithium to silver of 8:2 were put together, heated until completely melted, stirred evenly, and a 45 μm lithium-silver alloy ribbon was prepared. Use this lithium-silver alloy strip as the negative electrode, and use a standard capacity density of 3mAh cm -2 The lithium iron phosphate is used as the positive electrode, and the full battery LFP / / 8Li2Ag is assembled. After the assembled full battery LFP / / 8Li2Ag is placed for 4 hours, the constant current charge and discharge test is carried out with the battery test equipment, and the results are shown in figure 2 .

[0063] figure 2 It is a schematic diagram of the battery cycle results in Example 2 of the present invention.

[0064] Such as figure 2 As shown, the abscissa indicates the number of cycles of the full battery, and the ordinate indicates the discharge capacity density of the full battery. From figure 2 It can be seen that the first discharge capacity density o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com