Back cavity gap circularly polarized millimeter wave antenna based on substrate integrated waveguide (SIW)

A substrate-integrated waveguide and millimeter-wave antenna technology, which is applied in slot antennas, antenna grounding switch structural connections, and radiating element structural forms, etc., can solve problems such as narrow axial specific bandwidth of millimeter-wave circularly polarized antennas, low antenna gain and efficiency, etc. problem, to achieve the effect of compact structure, high gain, and overcoming the complexity of the feeding structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

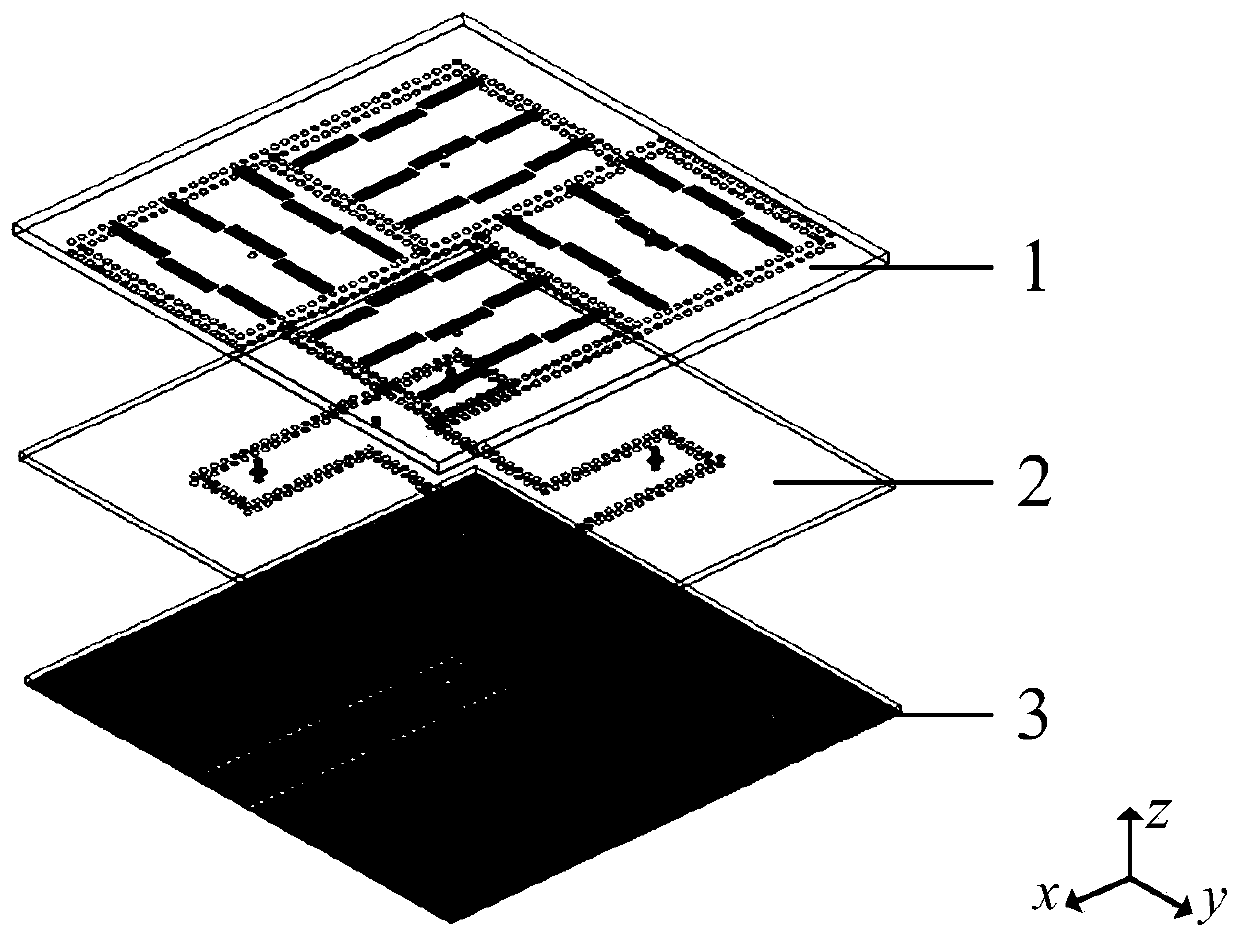

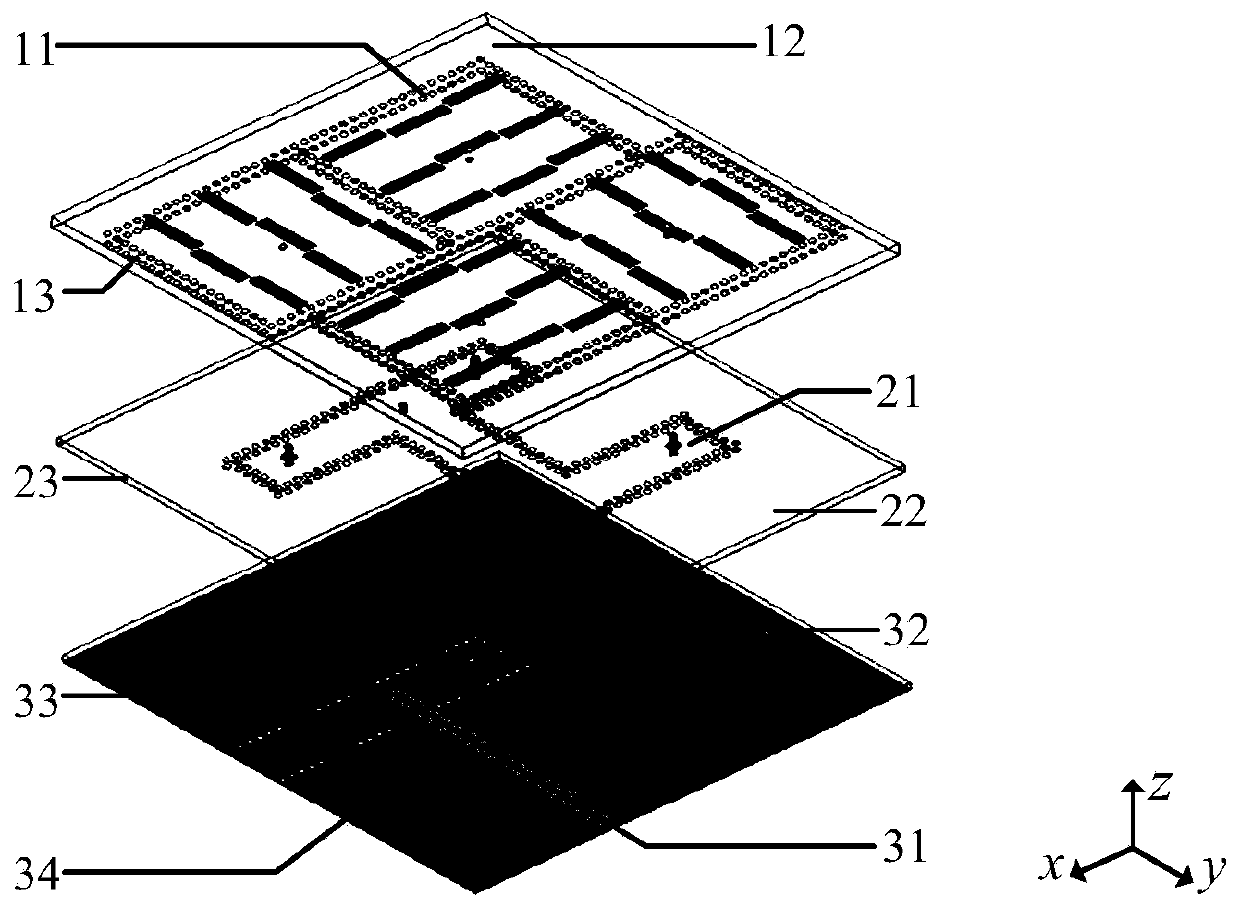

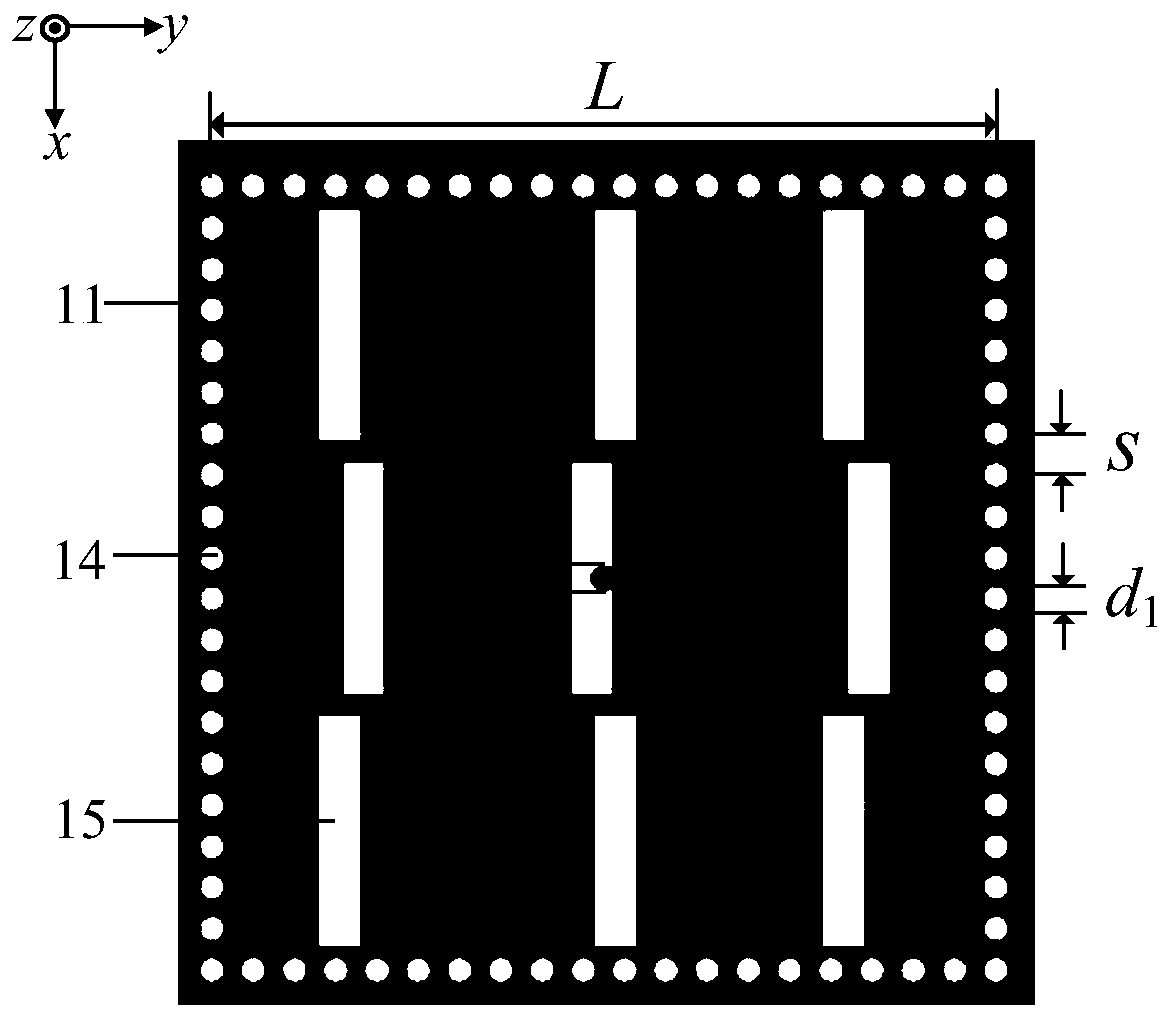

[0039] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , a cavity-backed slot circularly polarized millimeter-wave antenna based on a substrate-integrated waveguide SIW, its structure includes a radiation layer 1, a power layer 2, and a feed layer 3 from top to bottom, and the radiation layer 1 consists of four sequential The SIW square resonant cavity 11 arranged in rotation, the first metal patch 12 and the first rectangular dielectric plate 13 are composed; the power layer 2 is composed of a power divider 21, a second metal patch 22 and a second rectangular dielectric plate 23 composition; the feed layer 3 is composed of a rectangular SIW structure 31, a third metal patch 32, a third rectangular dielectric plate 33 and a fourth metal patch 34; the first metal patch 12, the second metal patch 22 are respectively covered on the upper surface of the first rectangular dielectric plate 13 and the second rectangular dielectric plate 23; the third metal patc...

Embodiment 2

[0053] The structure of this embodiment is the same as that of Embodiment 1, only the following parameters have been adjusted:

[0054] The side length L of the SIW square resonant cavity 11 is 15mm; the diameters of the first metal through hole 14, the second metal through hole 24 and the third metal through hole 35 are d 1 , where d 1 =0.45mm, and the distance between the centers of adjacent through holes is S=0.76mm; the length of the rectangular slit 15 is S L , the width is S W , where S L =4.46mm, S W =0.853mm; the diameter d of the through hole 16 2 =0.45mm; the length of the work-layered rectangular coupling gap 25 is L 1 , the width is W 1 , where L 1 =4.31mm, W 1 =0.2mm; the inner and outer diameters of the circular coupling slit 26 are respectively d 2 、d 3 , where d 2 = 0.45mm, d 3 =0.85mm; the diameter d of the circular impedance matching slit 27 4 =0.45mm; the distances between the circular impedance matching slit 27 and the two circular coupling sli...

Embodiment 3

[0056] The structure of this embodiment is the same as that of Embodiment 2, only the following parameters have been adjusted:

[0057] The side length L of the SIW square resonant cavity 11 is 15.4mm; the diameters of the first metal through hole 14, the second metal through hole 24 and the third metal through hole 35 are d 1 , where d 1 =0.55mm, and the distance between the centers of adjacent through holes is S=0.84mm; the length of the rectangular slit 15 is S L , the width is S W , where S L =4.56mm, S W =0.867mm; the diameter d of the through hole 16 2 =0.49mm; the length of the work-layered rectangular coupling gap 25 is L 1 , the width is W 1 , where L 1 =4.37mm, W 1 =0.24mm; the inner and outer diameters of the circular coupling slit 26 are respectively d 2 、d 3 , where d 2 = 0.49mm, d 3 =0.91mm; the diameter d of the circular impedance matching slit 27 4 =0.47mm; the distances between the circular impedance matching slit 27 and the two circular coupling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com