A kind of manufacturing method of magnetic strip magnetized board

A manufacturing method and technology of magnetic strip, which can be applied to magnetic objects, inductance/transformer/magnet manufacturing, circuits, etc., can solve the problems of slow production speed of magnetic strip magnetizing plate, difficult installation of magnetizing wire, damage to insulation structure, etc. , to achieve the effect of improving the success rate of one-time installation, saving stirring time and reducing curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

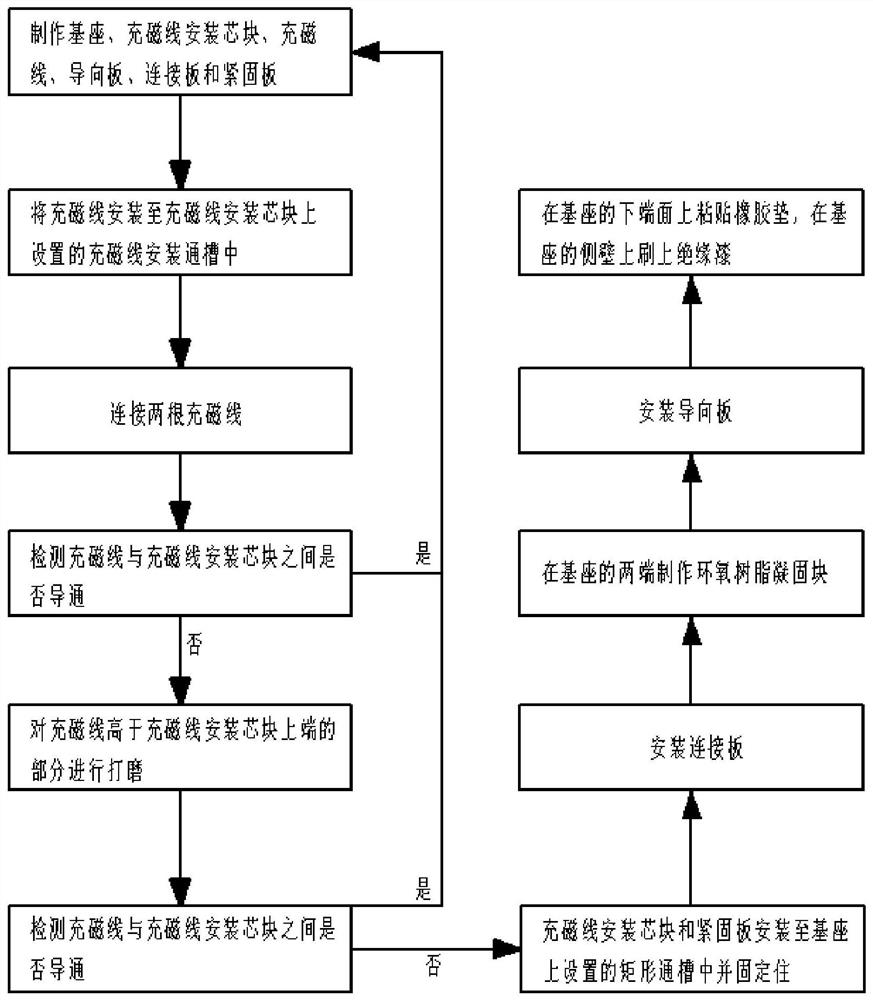

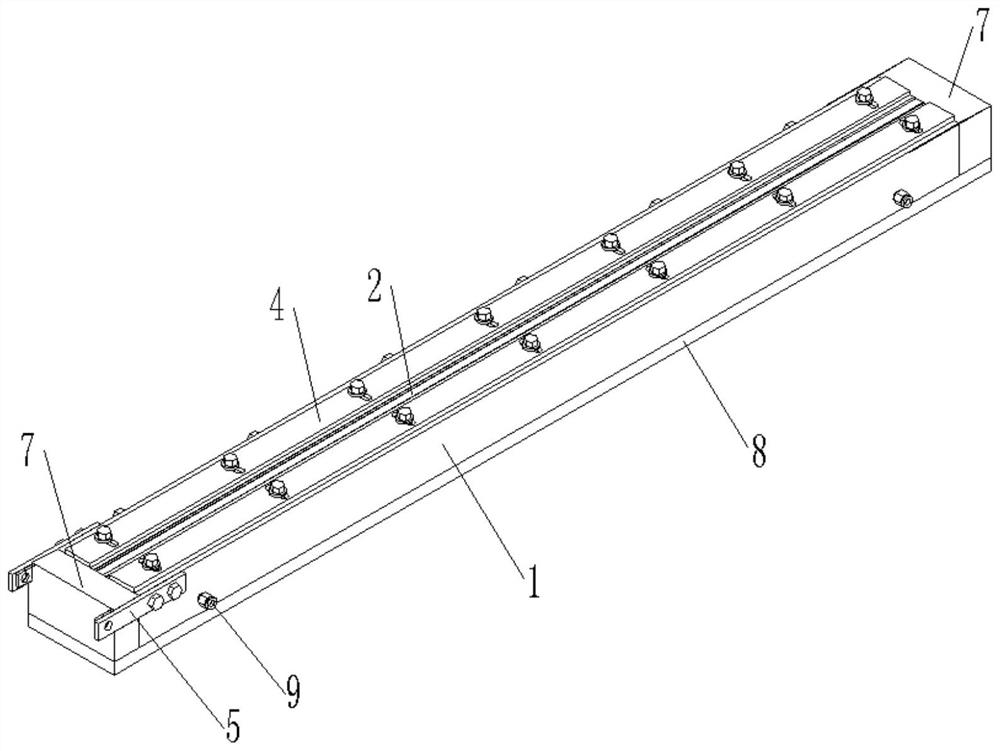

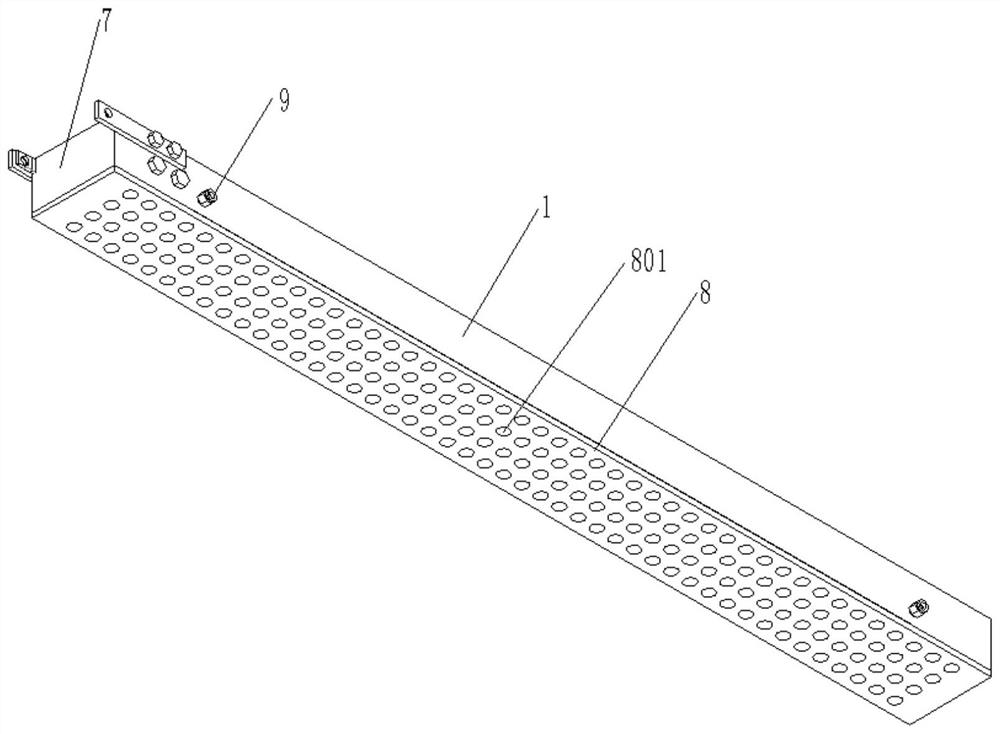

[0042] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 , a kind of manufacture method of magnetic strip magnetization board, comprises the following steps:

[0043] S1. Make base 1, magnetizing wire installation core block 2, magnetization wire 3, guide plate 4, connecting plate 5 and fastening plate 6, base 1 and magnetization wire installation core block 2, guide plate 4 and fastening plate The length of the fixed plate 6 is the same; when making the base 1, according to the drawing of the magnetized plate to be made, select the square steel with the same width and height as the magnetized plate base 1, and intercept the same length as the base, Along the length direction of the intercepted square steel, use a wire cutting machine to longitudinally cut the square steel into two parts, the upper steel and the lower steel. The machining allowance of wire cutting is small and the machining accuracy is high. ...

Embodiment 2

[0055] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9, a kind of manufacture method of magnetic strip magnetization board, comprises the following steps:

[0056] S1. Make base 1, magnetizing wire installation core block 2, magnetization wire 3, guide plate 4, connecting plate 5 and fastening plate 6, base 1 and magnetization wire installation core block 2, guide plate 4 and fastening plate The length of the fixed plate 6 is the same; when making the base 1, according to the drawing of the magnetized plate to be made, select the square steel with the same width and height as the magnetized plate base 1, and intercept the same length as the base, Use a wire cutting machine along the length direction of the intercepted square steel to longitudinally cut the square steel into two parts, the upper steel and the lower steel, and mill a rectangular slot 101 along the length direction on the upper end surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com