A z-source inverter buck-boost control method for electric vehicle motor drive

A source inverter, motor drive technology, applied in the direction of AC motor control, electric vehicles, motors, etc., can solve the problems of output current distortion, current ripple amplitude increase, low energy conversion efficiency, etc., to reduce the voltage Effects of current stress, reduced shoot-through duty cycle, easy automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

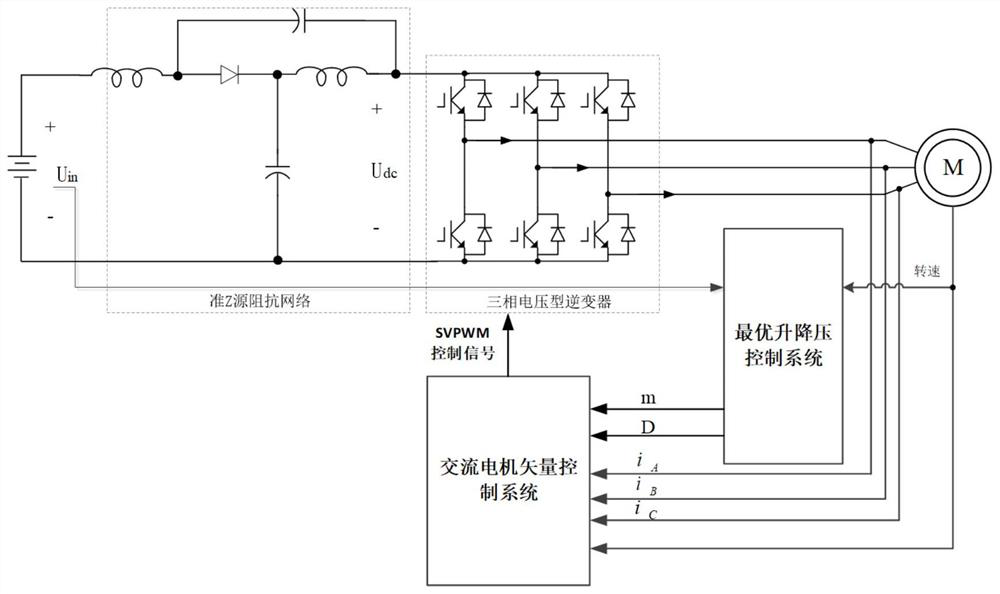

[0057] Embodiments of the present invention take the quasi-Z source inverter to drive the AC motor as an example, as figure 1 As shown, it includes a quasi-Z source inverter composed of a battery, a quasi-Z source impedance network and a three-phase voltage type inverter, a motor, an AC motor vector control system and an optimal buck-boost control system; the battery passes through the quasi-Z source The inverter supplies power to the motor after conversion, and the optimal buck-boost control system collects motor information, generates the optimal buck-boost control signal and sends it to the AC motor vector control system, and the AC motor vector control system uses the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com