A new device and method for rapid and continuous generation of hydrates on trays

A technology of hydrates and trays, applied in feeding devices, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as storage difficulties, slow hydrate formation steps, and limited gas-liquid interface mass transfer, etc., to achieve Enhanced self-cleaning ability, stable impact-resistant mechanical properties, and reasonable device structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

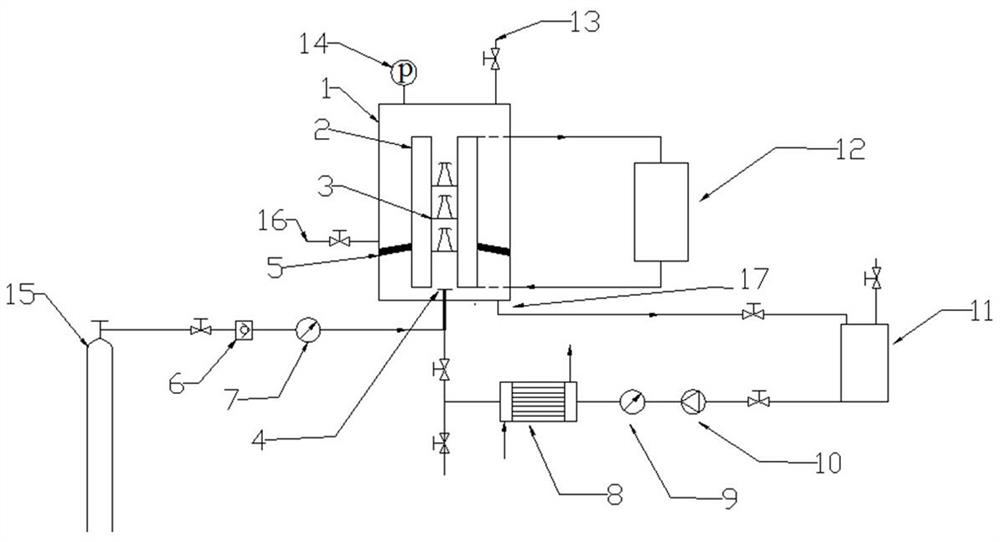

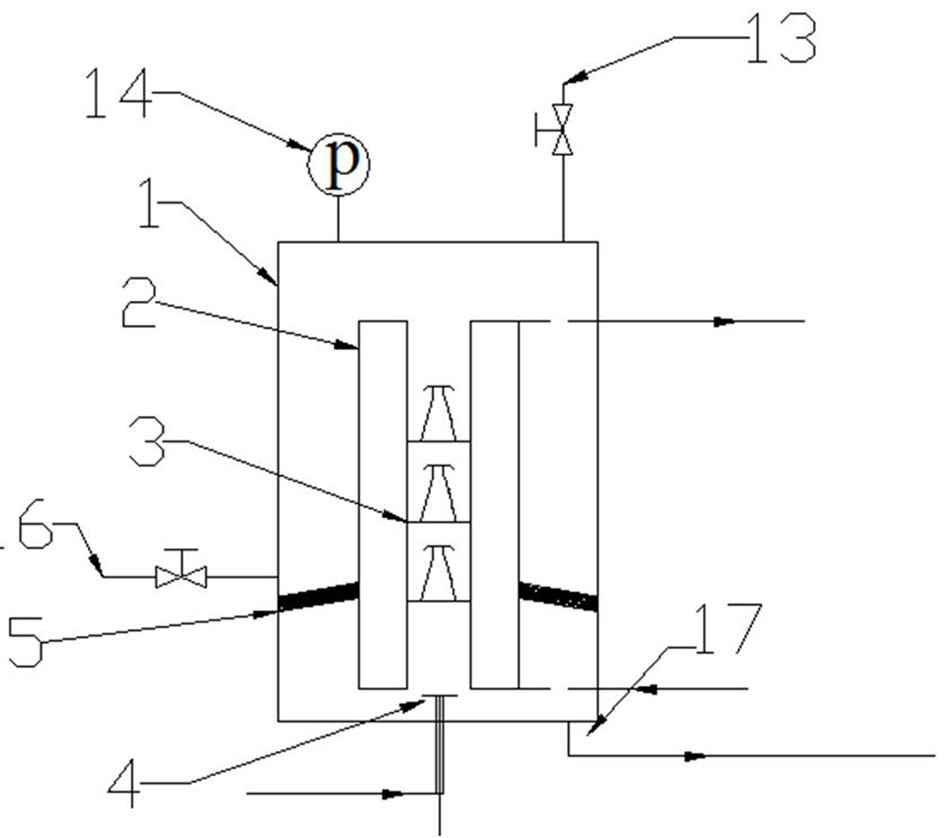

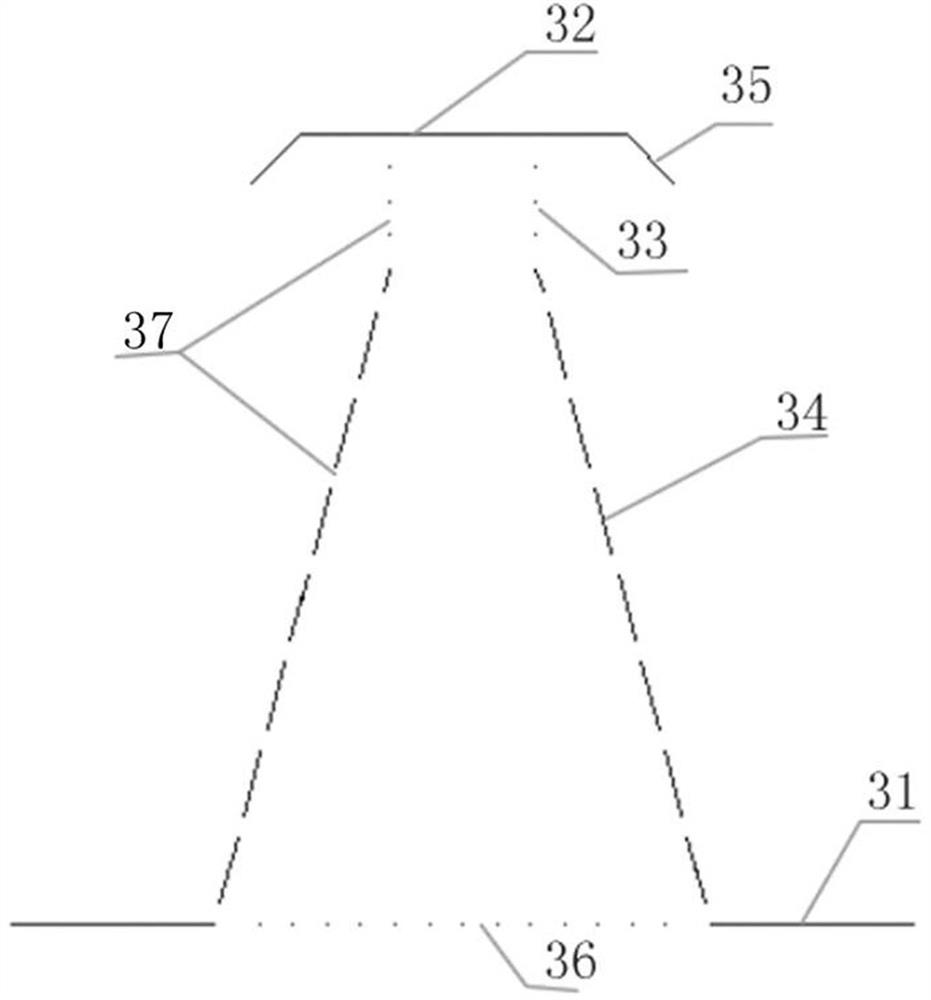

[0030] Such as figure 1 , figure 2 , image 3 and Figure 4 A new type of rapid and continuous hydrate generation device with trays is shown, including a reactor, the reactor includes an inner cylinder 2 and an outer cylinder 1, the inner cylinder 2 is the hydrate formation zone, and the outer cylinder 1 zone is the hydrate Aggregation and separation areas. A circulating cooling device 12 is arranged outside the inner cylinder 2, a sieve plate 5 is installed between the inner cylinder 2 and the outer cylinder 1 inclined toward the outer cylinder 1, and a circulating water outlet and a discharge port 16 are arranged at the bottom of the outer cylinder 1, and the discharge port 16 is located on the sieve plate 5 above.

[0031] An inner jacket is arranged on the outer side of the 2 walls of the inner cylinder, and the inner jacket is equipped with a circulating cooling liquid. The circulating cooling liquid inlet and the circulating cooling liquid outlet of the inner jacket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com