Supported photocatalyst nise 2 The preparation method of /cds and its application

A photocatalyst, supported technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high cost and easy recombination of charge carriers, achieve rich applications and speed up separation and transfer and promote the effect of hydrogen production activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation steps of the present invention are as follows:

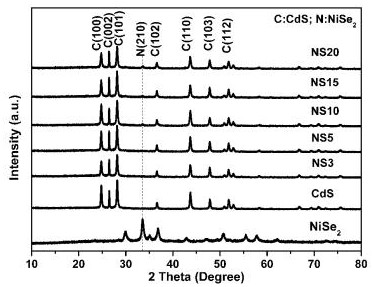

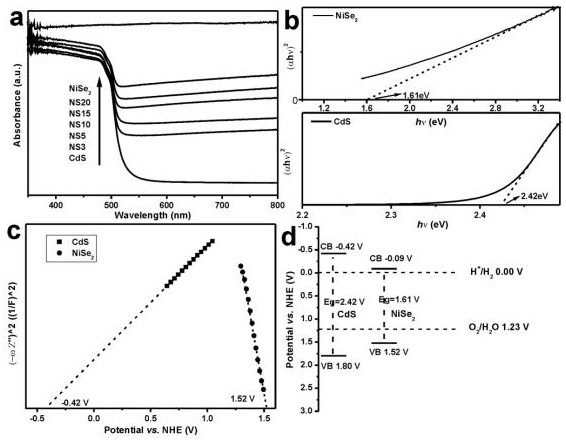

[0018] Preparation of CdS nanoparticles: Weigh 12.5 mmol of cadmium nitrate tetrahydrate and 37.5 mmol of thiourea into a 100 mL reaction kettle lining, add 60 ml of ethylenediamine and stir to dissolve, then seal it in a high-pressure reaction The kettle was heated to 160 °C in an electric blast drying oven and kept for 24 h. After cooling down to room temperature, the precipitate was centrifuged, washed several times with water and ethanol, and dried in a vacuum oven at 80 °C for 8 h to obtain CdS nanorods.

[0019] Preparation of NaHSe solution: Weigh 2.857 g of sodium hydroxide and 0.228 g of selenium powder into a 50ml reaction kettle, add 25ml of deionized water and stir for 0.5 h, then seal it in a high-pressure reaction kettle, and place it in an electric blast drying oven Heat to 180 °C and keep it warm for 12 h, and wait for it to cool down to room temperature for later use.

[0020] Dissolve a...

Embodiment 1

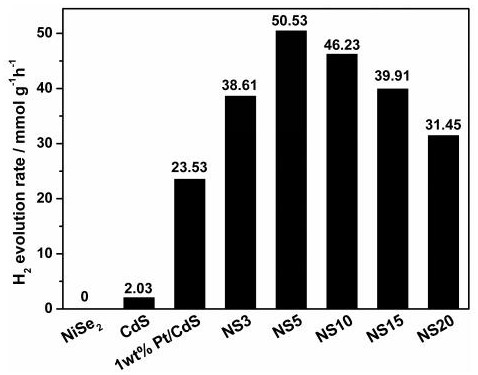

[0022] Dissolve a certain amount of nickel nitrate hexahydrate, trisodium citrate (27.69 μmolL trisodium citrate, the molar ratio of the former two is 1:1) and quantitative hexamethylenetetramine (0.25 mmol) in 40 mL of deionized water , then add 200 mg of CdS powder, ultrasonically disperse evenly, then transfer to the autoclave, keep at 120 °C for 12 h, and finally cool down to room temperature naturally; then add 0.719 ml of the prepared NaHSe solution into the above reaction autoclave The samples were kept at 140 °C for 12 h, and then naturally cooled to room temperature. The obtained samples were centrifuged with deionized water and absolute ethanol, and dried in a vacuum oven to obtain NiSe 2 NiSe with a loading of 3wt% 2 / CdS(NS 3 ) heterojunction photocatalysts. Accurately weighed 5 mg of the synthesized powder catalyst was placed in a photo-splitting water reactor to test the hydrogen production performance of photo-splitting water.

Embodiment 2

[0024] Dissolve a certain amount of nickel nitrate hexahydrate, trisodium citrate (46.15 μmolL trisodium citrate, the molar ratio of the former two is 1:1) and quantitative hexamethylenetetramine (0.25 mmol) in 40 mL of deionized water , then add 200 mg of CdS powder, ultrasonically disperse evenly, transfer to the autoclave, keep at 120 °C for 12 h, and finally cool down to room temperature naturally; then add 1.199 ml of prepared NaHSe solution into the autoclave after the above reaction The samples were kept at 140 °C for 12 h, and then naturally cooled to room temperature. The obtained samples were centrifuged with deionized water and absolute ethanol, and dried in a vacuum oven to obtain NiSe 2 NiSe with a loading of 5wt% 2 / CdS(NS 5 ) heterojunction photocatalysts. Accurately weighed 5 mg of the synthesized powder catalyst was placed in a photo-splitting water reactor to test the hydrogen production performance of photo-splitting water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com