Vehicle dashboard framework material based on long glass fiber reinforced polypropylene and preparation method thereof and vehicle

A skeleton material, polypropylene technology, used in dashboards, vehicle parts, transportation and packaging, etc., can solve the problems of product odor and mechanical properties decline, interference with the combination of glass fiber and compatibilizer, and high temperature failure of flavors. The technological process and control conditions are simple and environmentally friendly, the odor performance is superior, and the mechanical properties are good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 50 parts by weight of polypropylene resin, 50 parts by weight of long glass fiber reinforced polypropylene and 2.5 parts by weight of essence are evenly blended, added to the feeding port of a single-screw extruder, heated and melted, extruded, cooled, After being blown dry and pelletized, the frame material of the instrument panel of the vehicle is obtained.

[0028] Wherein, the above-mentioned uniform blending process can be realized by adding raw materials into a mixer and mixing them uniformly.

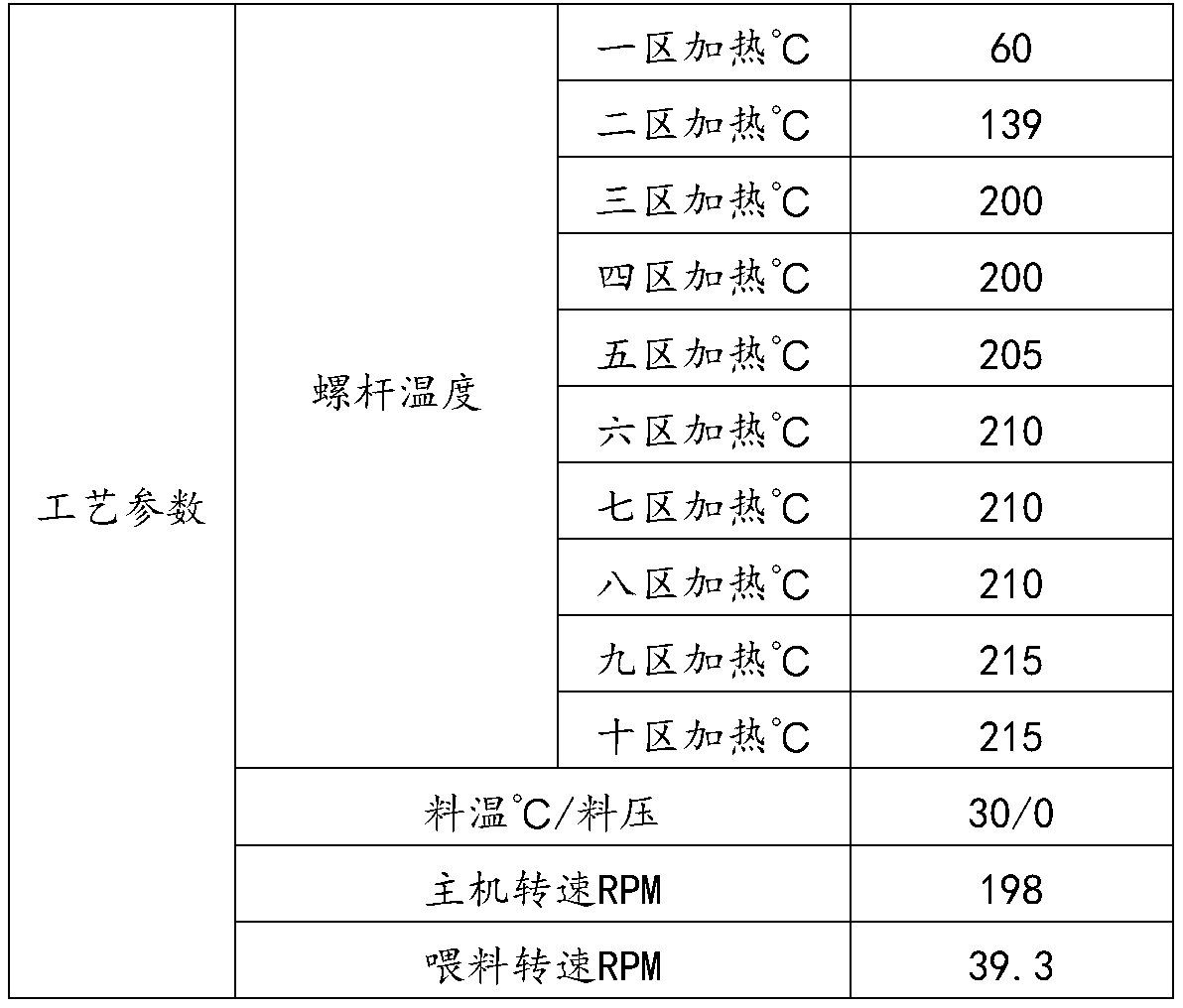

[0029] Wherein, the glass fiber content in the long glass fiber-reinforced polypropylene is 40%, and the working parameters of the single-screw extruder in the above-mentioned feeding, heating and melting and basic processes are shown in the following table:

[0030] Table 1: Working parameters of the single-screw extruder in Example 1:

[0031]

[0032] The relevant performance test results of the products in this example are shown in Table 6.

Embodiment 2

[0034] 40 parts by weight of polypropylene resin, 55 parts by weight of long glass fiber reinforced polypropylene and 3‰ parts by weight of essence are evenly blended, added to the feed port of a single-screw extruder, heated and melted, extruded, cooled, After being blown dry and pelletized, the frame material of the instrument panel of the vehicle is obtained.

[0035] Wherein, the above-mentioned uniform blending process can be realized by adding raw materials into a mixer and mixing them uniformly.

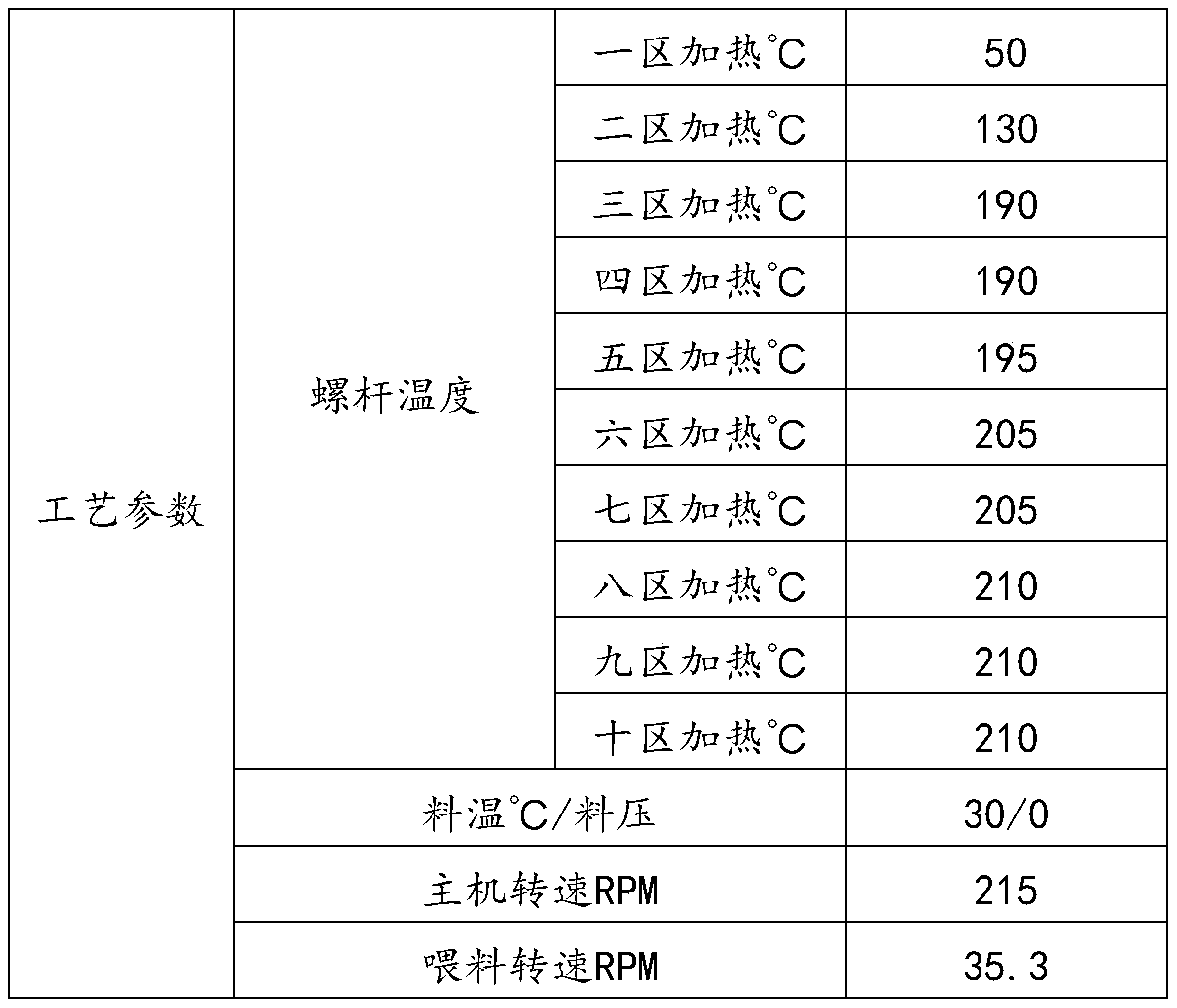

[0036] Wherein, the glass fiber content in the long glass fiber-reinforced polypropylene is 40%, and the working parameters of the single-screw extruder in the above-mentioned feeding, heating and melting and basic processes are shown in the following table:

[0037] Table 2: Working parameters of single-screw extruder in embodiment 2:

[0038]

[0039] The relevant performance test results of the products in this example are shown in Table 6.

Embodiment 3

[0041] 65 parts by weight of polypropylene resin, 45 parts by weight of long glass fiber reinforced polypropylene and 4.3 parts by weight of essence are evenly blended, added to the feeding port of a single-screw extruder, heated and melted, extruded, cooled, After being blown dry and pelletized, the frame material of the instrument panel of the vehicle is obtained.

[0042] Wherein, the above-mentioned uniform blending process can be realized by adding raw materials into a mixer and mixing them uniformly.

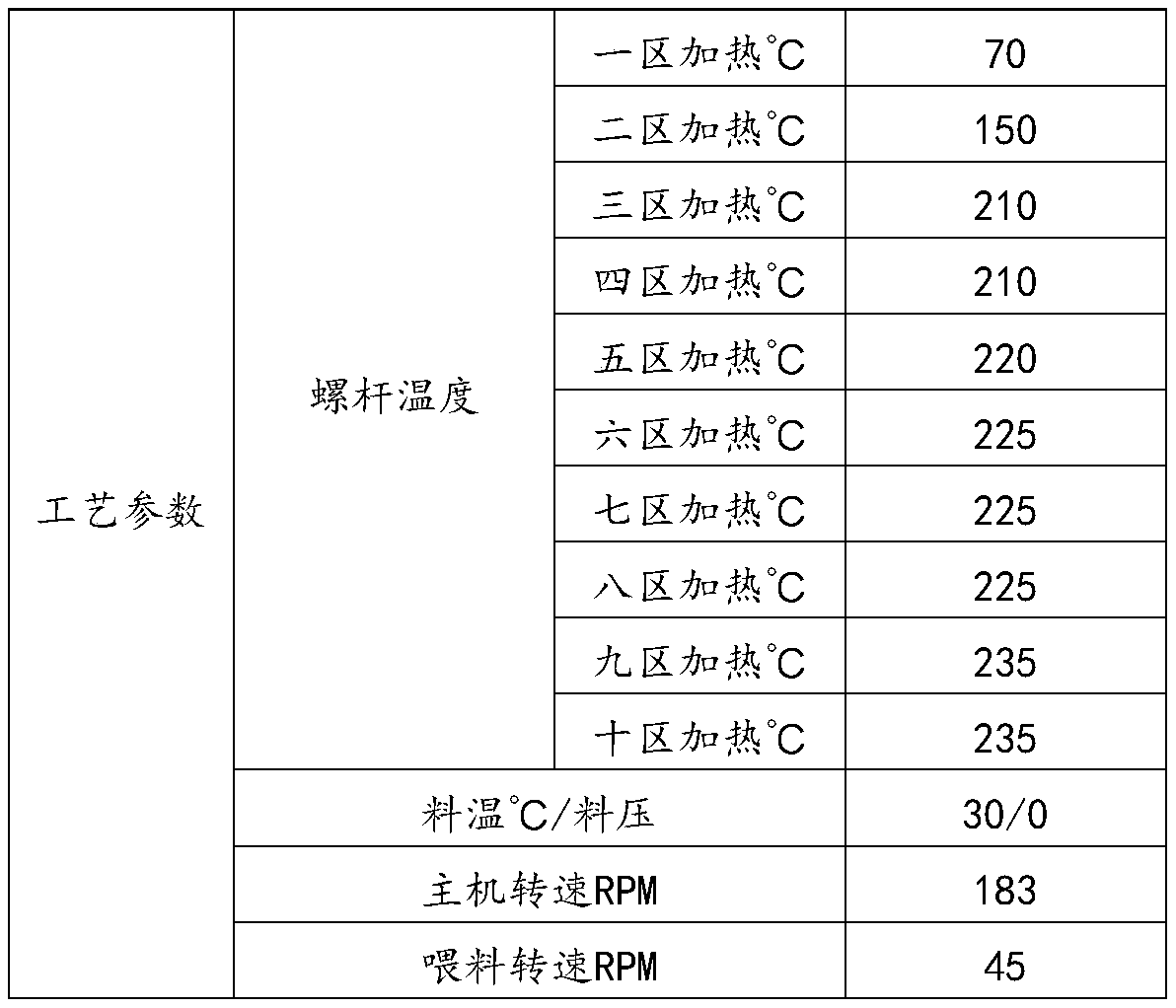

[0043] Wherein, the glass fiber content in the long glass fiber-reinforced polypropylene is 20%, and the working parameters of the single-screw extruder in the above-mentioned feeding, heating and melting and basic processes are shown in the following table:

[0044] Table 3: Operating parameters of single-screw extruder in embodiment 3:

[0045]

[0046] The relevant performance test results of the products in this example are shown in Table 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com