Single-needle stitching mechanism and stitching process for automatic hosiery knitting machine

A sock knitting machine and single-needle technology, which is applied to the needle base of the sewing machine, the looping machine for connecting knitted fabrics, sewing equipment, etc., and can solve the problem of large needle holes, easy stitches, poor working stability and easy leakage. Needles and other problems, to achieve the effect of flat, good extensibility, simple work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

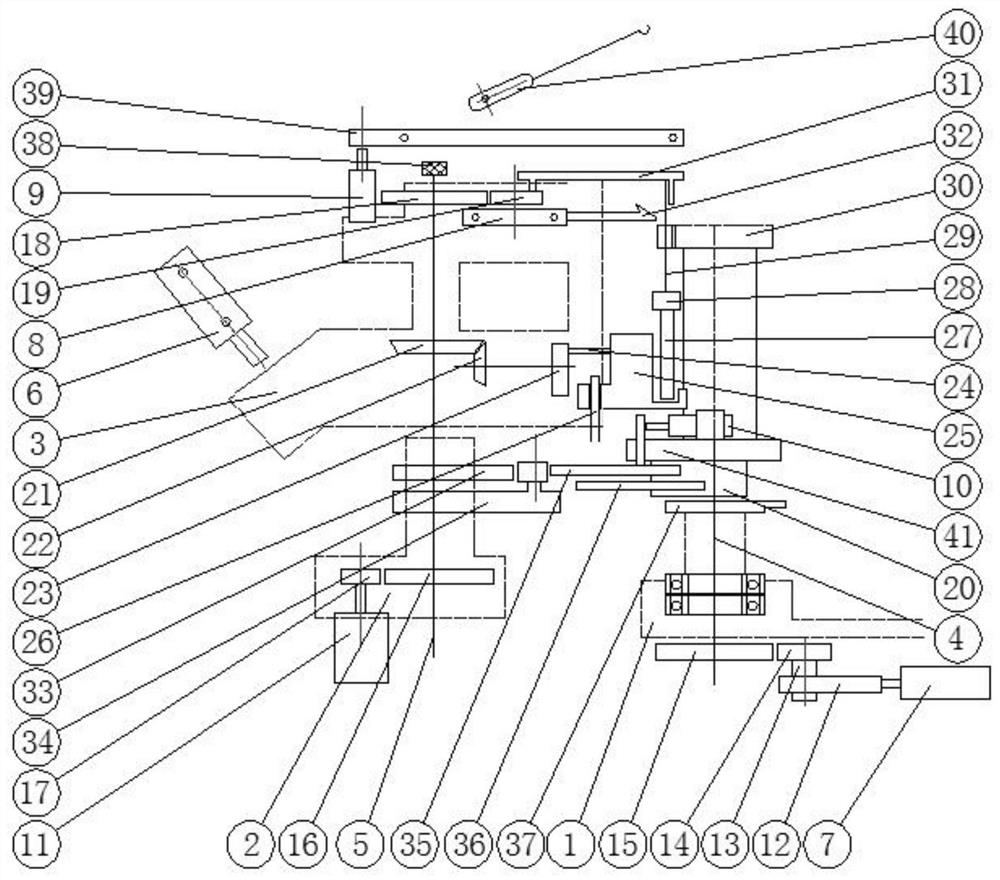

[0028] combine figure 1 , the present invention is described in detail. The invention relates to a single-needle stitching mechanism for the toe of an automatic hosiery machine, comprising a single-needle stitching control system, a stitching initial position reset system and a single-needle stitching system.

[0029] The single-needle stitching control system is made up of the stepper motor 11 fixedly arranged on the base two 2, the spur gear three 17, the spur gear two 16, the cam 33, the cam connecting rod 34, the brace 35, and the stop card 36.

[0030] The suturing starting position reset system consists of double-position cylinders 7, racks 12, conjoined pinions 13, conjoined large gears 14, flat gears 15, support head control boards 41, Cylinder two 10, half-moon ratchet 20, adjustment ring 37 are formed.

[0031] The single-needle su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com