Pneumatic control valve and gas-liquid pressure conversion control device

A technology of pneumatic control valve and air valve, which is applied in the direction of fluid pressure actuating device, accumulator device, mechanical equipment, etc., can solve the problems of large inner plate space of machine tool, enlarged oil tank volume, unstable oil supply pressure, etc. , to achieve the effect of simplifying the machine tool application circuit, simplifying the hydraulic system, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to describe the technical solutions disclosed in the present invention in detail, further elaboration will be given below in conjunction with specific embodiments and accompanying drawings.

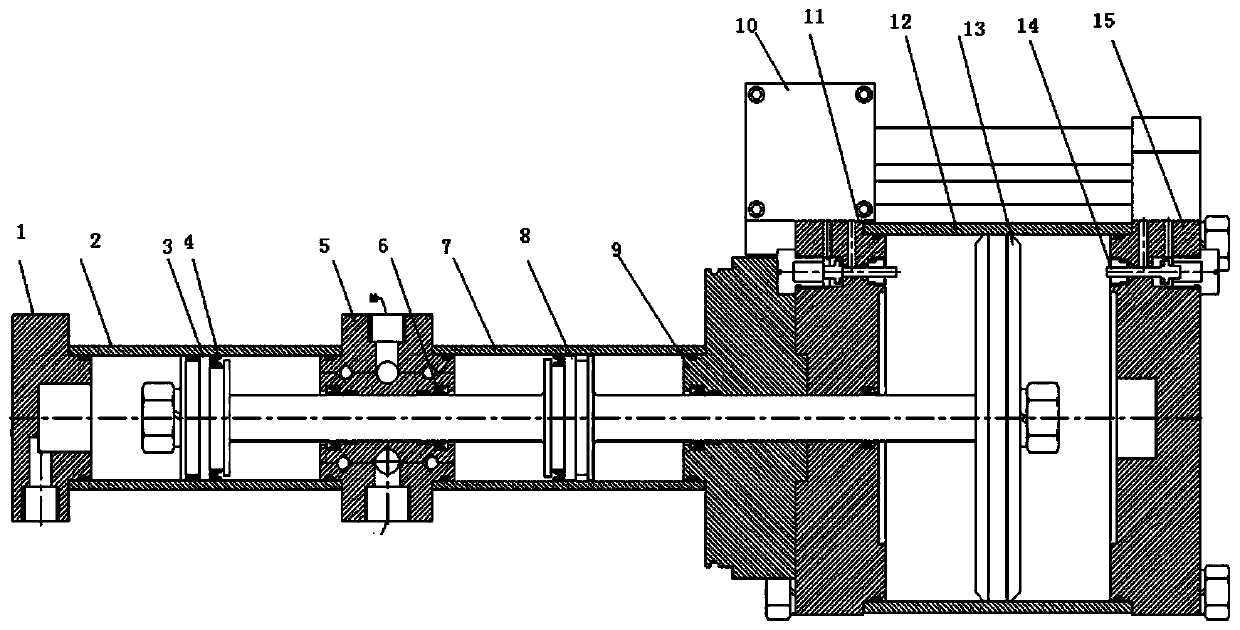

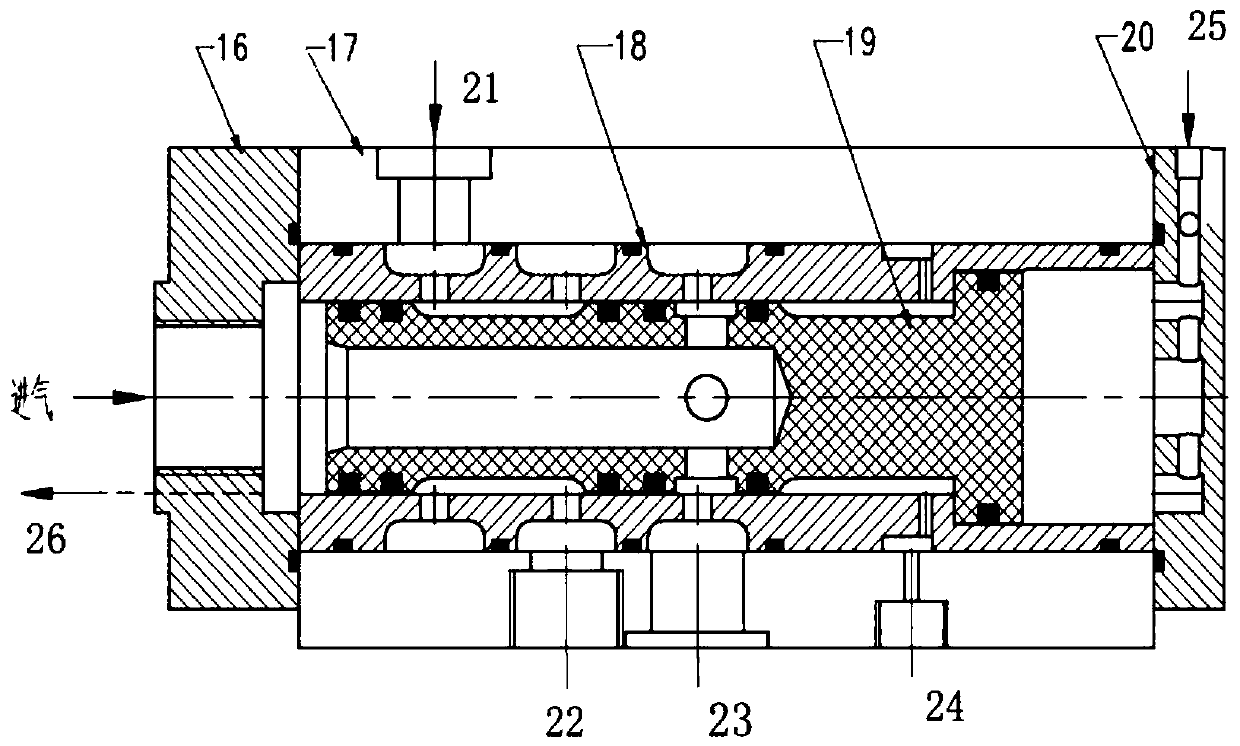

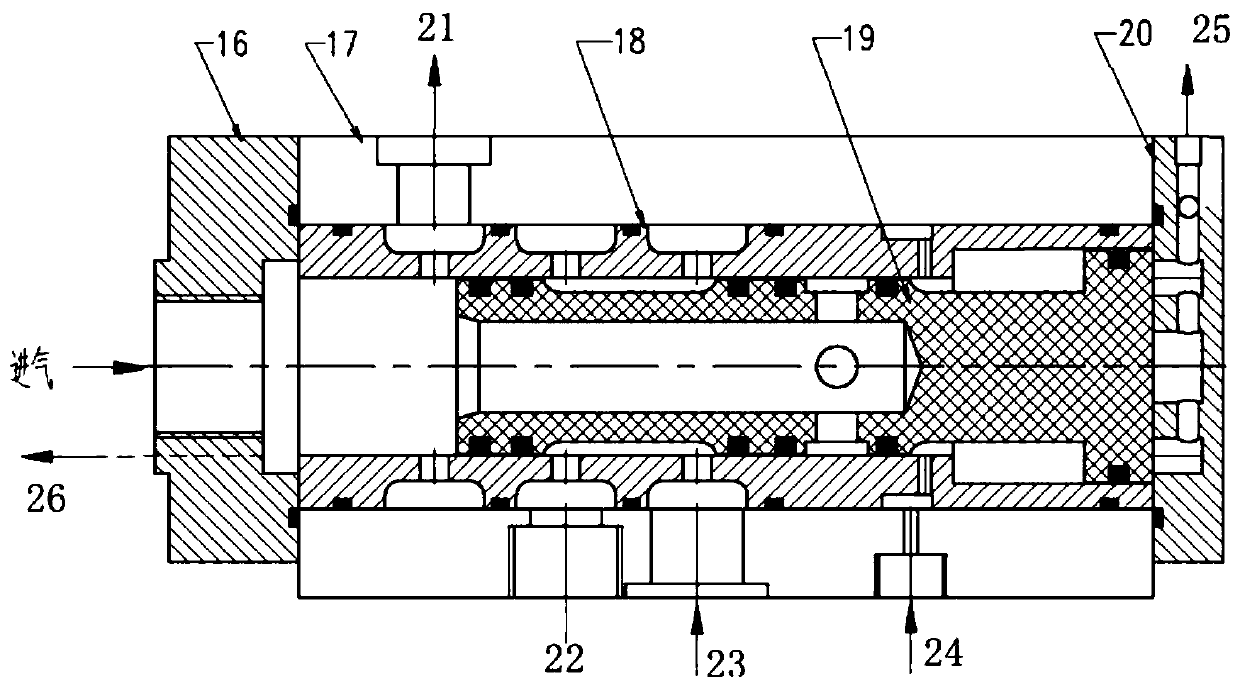

[0017] Aiming at the defects of traditional gas-liquid control devices or gas-liquid booster devices, the present invention provides a gas-hydraulic pressure conversion control device, which uses a combination of a large-diameter cylinder and a small-diameter hydraulic cylinder, and uses the push-pull reciprocating motion of the cylinder to drive The piston of the hydraulic cylinder reciprocates to complete the oil suction and oil discharge functions of the gas-hydraulic booster. The gas-liquid conversion control device uses a double-acting cylinder to drive two hydraulic cylinders connected in series through a piston rod. The pistons of the cylinder and the hydraulic cylinder are rigidly connected. Whether it is forward or backward, the two actions of oil suction and oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com