Single component continuous leak detection system and leak detection method

A leak detection, single technology, applied in the direction of detecting the appearance of fluid at the leak point, electrochemical variables of materials, liquid tightness measurement using liquid/vacuum degree, etc., which can solve the problem of complex environmental background composition and susceptible to environmental interference. , large detection error and other problems, to achieve the effect of satisfying continuous and rapid detection, high sensitivity and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

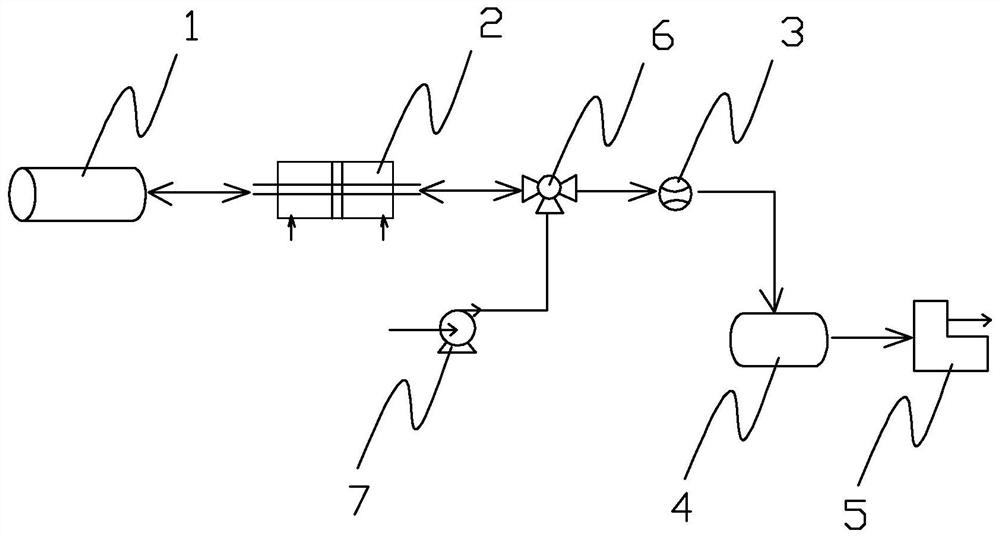

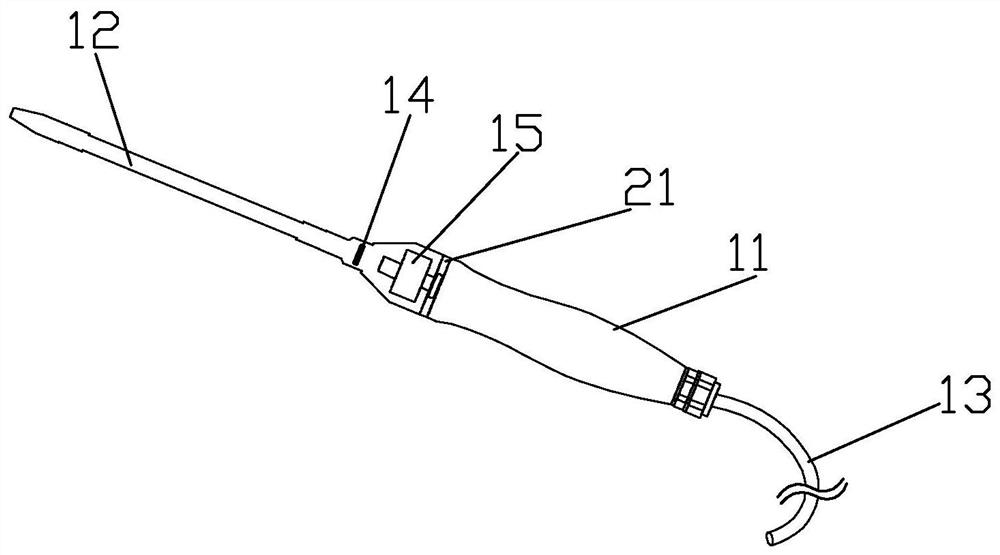

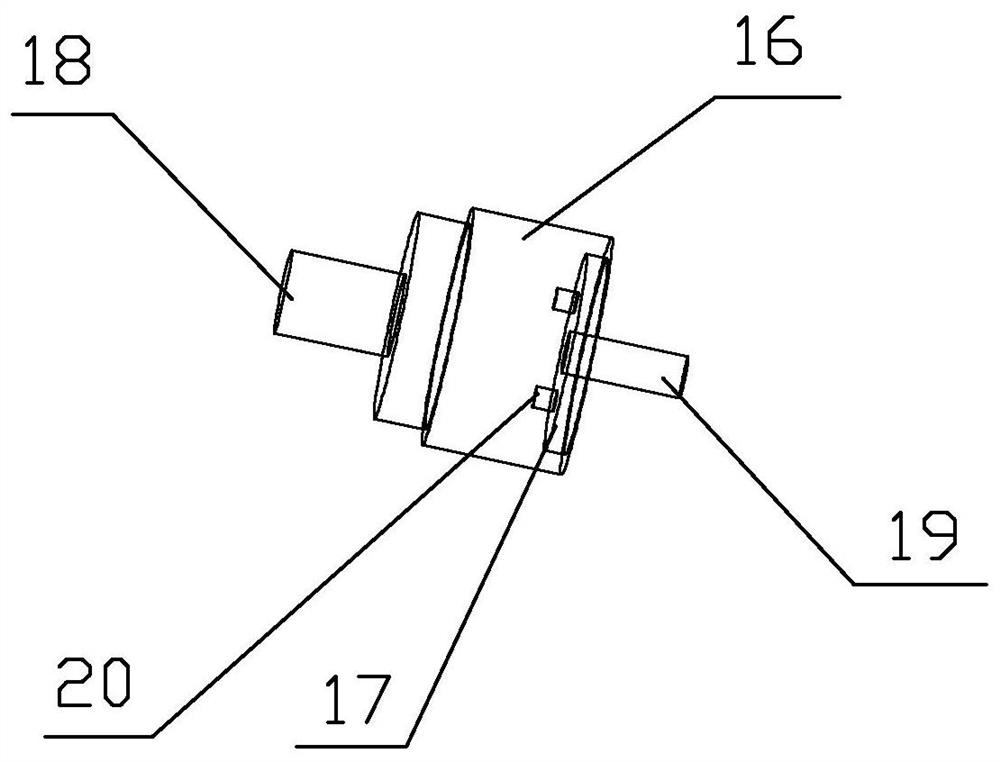

[0023] Embodiment: the single-component continuous leak detection system of this embodiment, such as figure 1As shown, it includes a sampling detection probe 1, a connector 2, a flow sensor 3, a buffer tank 4, a sampling air pump 5, a three-way solenoid valve 6, a blowback air pump 7 and a main control circuit. The sampling detection probe, connector, three-way solenoid valve, flow sensor, buffer tank and sampling gas pump are connected in sequence to form a measurement gas circuit. The common port and the normal opening of the three-way solenoid valve are respectively connected to the connector and the flow sensor. The one-way solenoid valve is connected to the connector and the flow sensor; the normally closed port of the three-way solenoid valve is connected to the back-blowing air pump. The detection probe constitutes a back-flush cleaning air circuit, the back-flush air pump is turned on, and the back-flush cleaning air circuit works to purify the measurement air circuit ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com