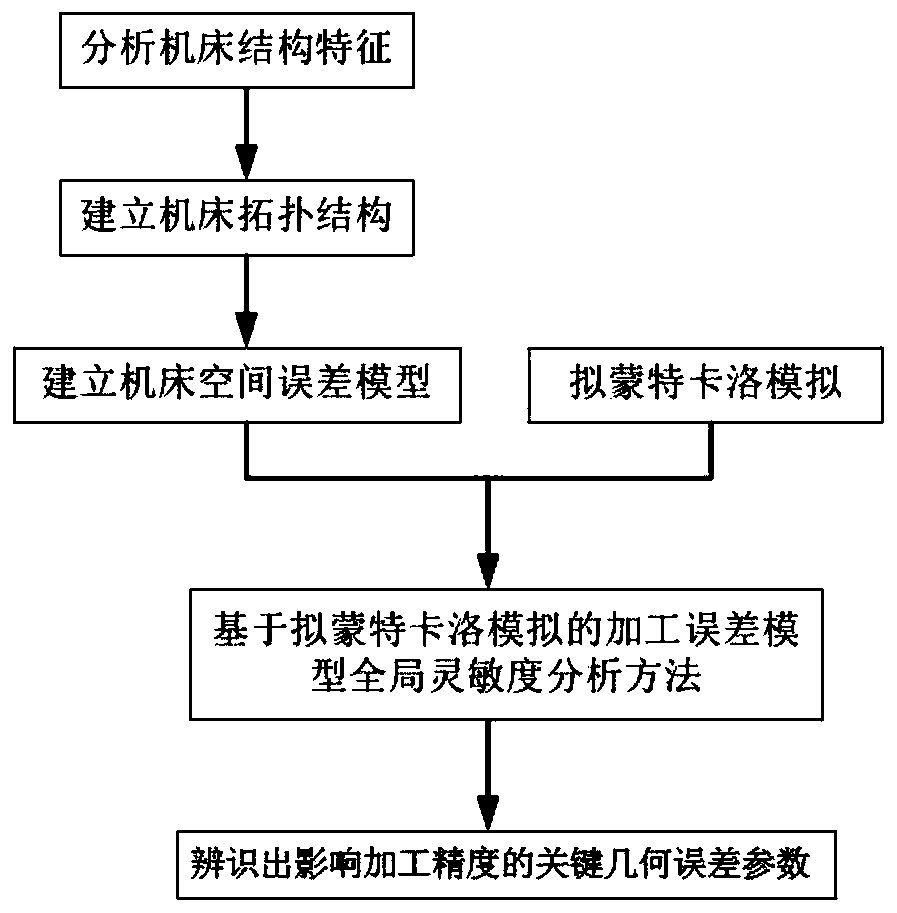

Processing error model global sensitivity analysis method based on quasi-Monte Carlo simulation

A quasi-Monte Carlo and sensitivity analysis technology, applied in the field of machine tool precision design, can solve problems such as complex structure of five-axis machine tools, many error factors involved, and complex processing and forming mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0138] The present invention takes a five-axis elevated beam mobile gantry CNC milling machine as an example to verify the identification method of the key geometric errors of the five-axis CNC milling machine.

[0139] Specifically include the following steps:

[0140] Step 1: Take the five-axis CNC machine tool as an example to establish the spatial error model of the machine tool;

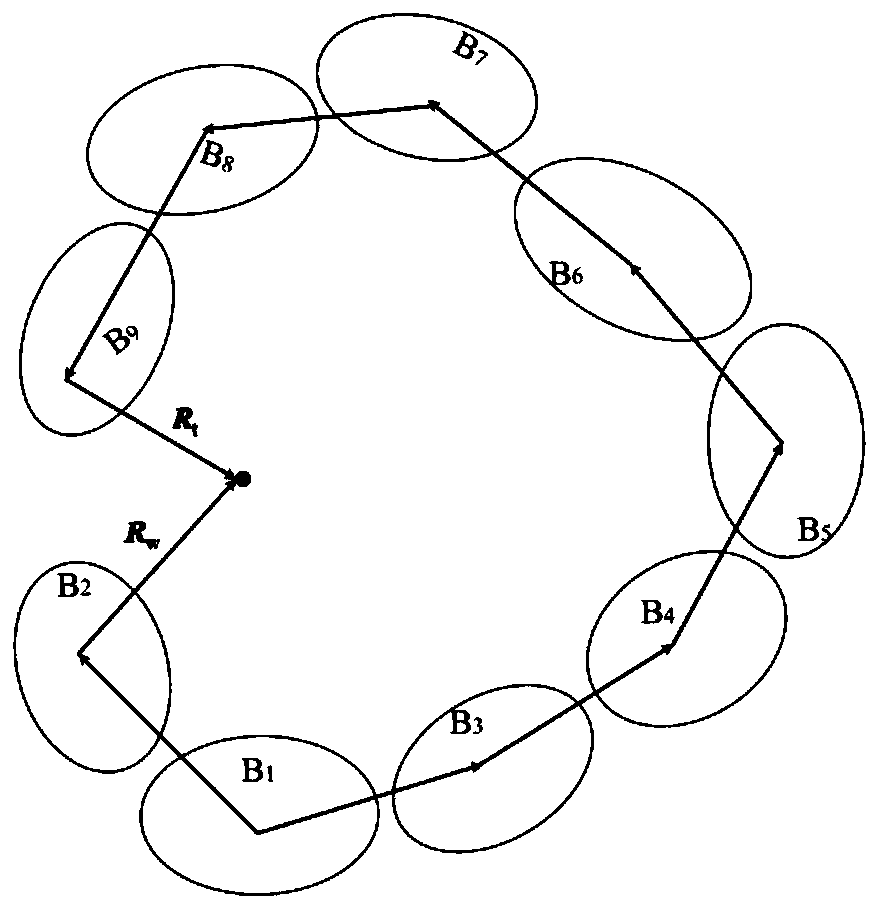

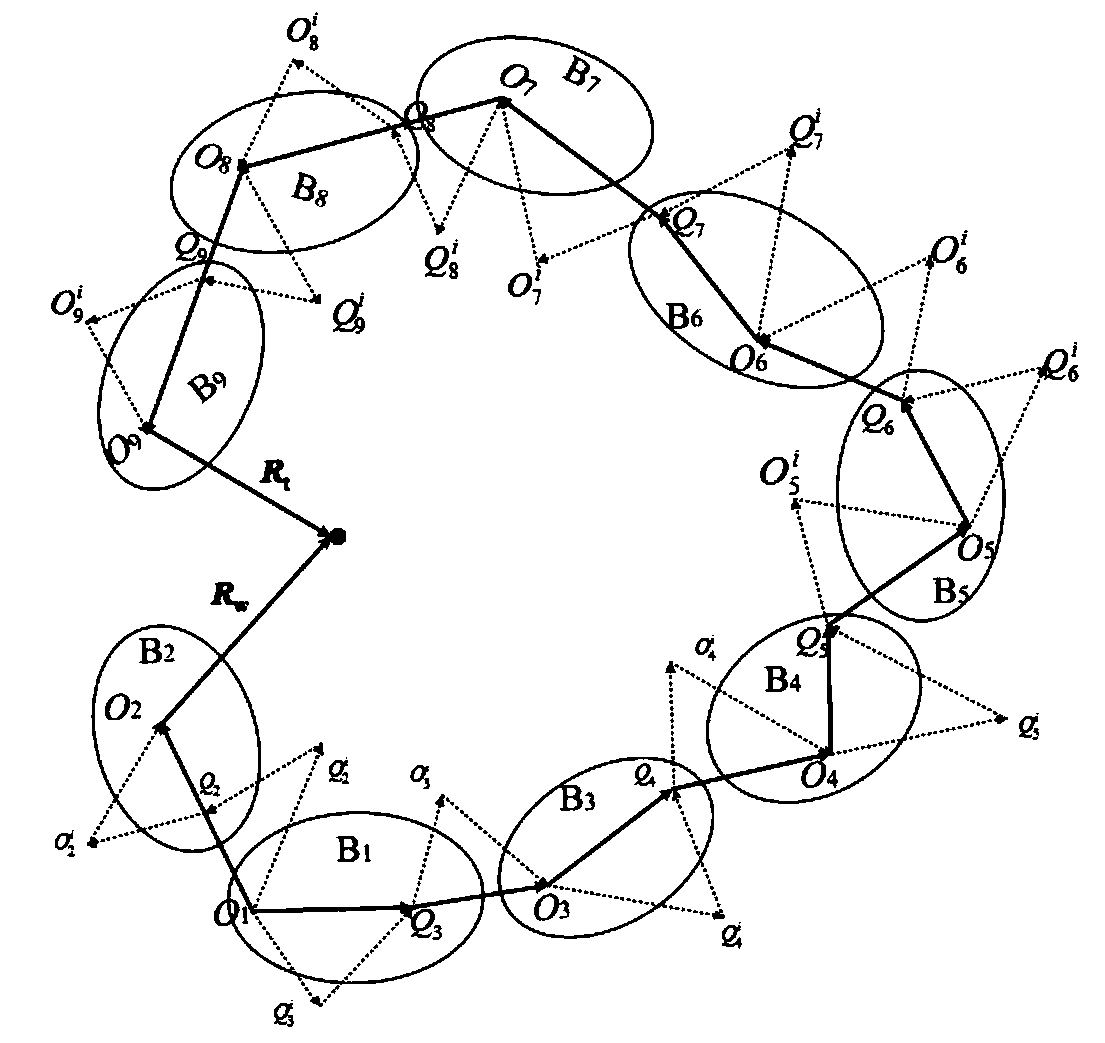

[0141] Based on the theory of multi-body system kinematics, the structure of the machine tool and the relationship between each body are described by topological structure diagram and low-order body array table, such as image 3 and shown in Table 1. Analyze the geometric error of CNC machine tools, establish a generalized coordinate system, use the characteristic matrix between adjacent bodies to express the positional relationship, and use the homogeneous transformation matrix to express the relationship between multi-body systems;

[0142] Step 1.1 establishes the topology of the five-axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com