Overhead line parallel gap protection device for power distribution network

A technology for protection devices and overhead lines, applied in circuit devices, emergency protection circuit devices, emergency protection circuit devices for limiting overcurrent/overvoltage, etc., can solve the problem of rising to the limit value, cost and lack of stability, etc. problems, to achieve the effect of easy disassembly, effective and safer protection, and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The invention will be described in detail below in conjunction with specific embodiments.

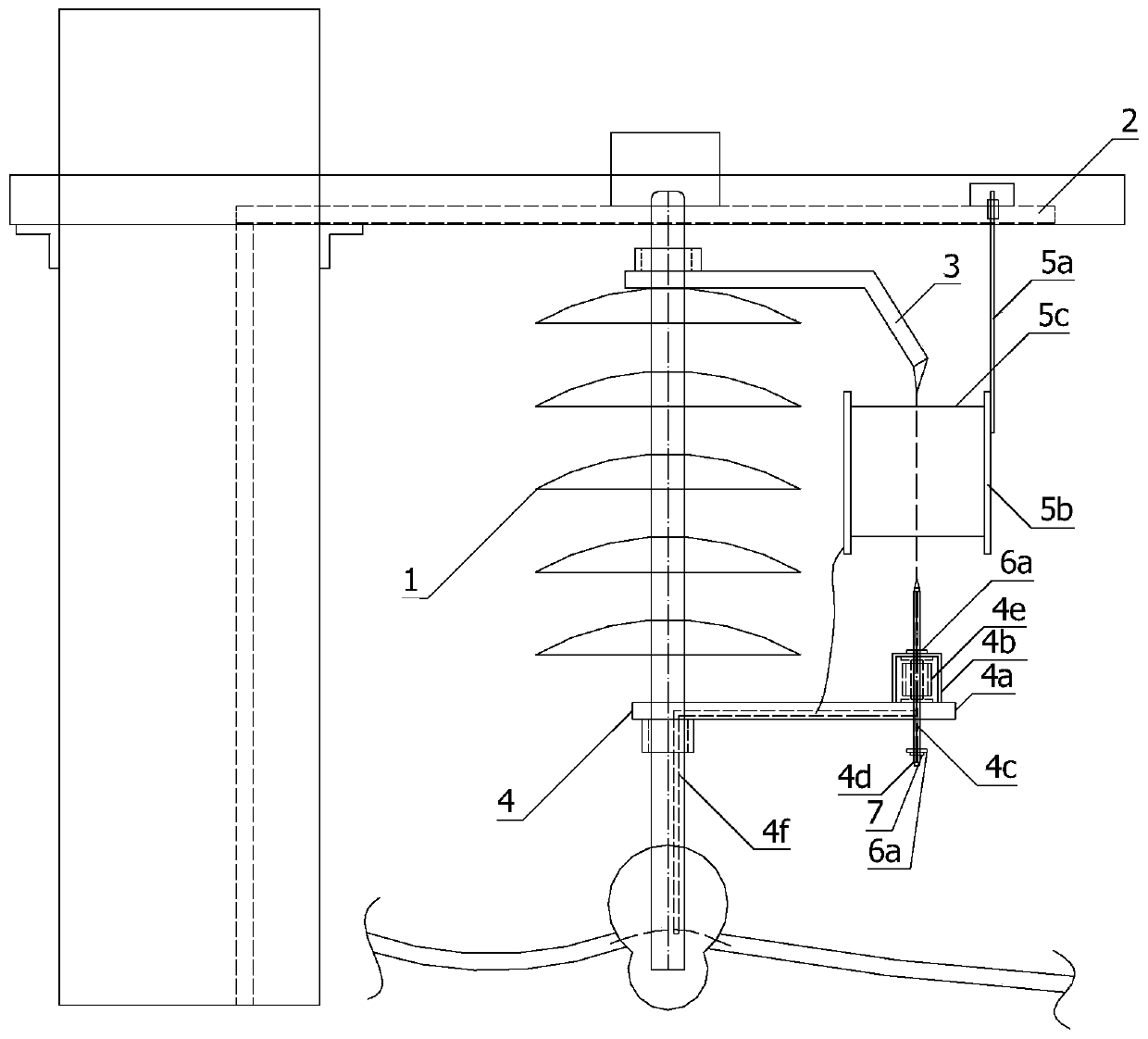

[0023] A parallel gap protection device for overhead lines in a power grid, comprising a pendent insulator 1 arranged between a tower pole and an overhead line, a parallel gap protection device arranged on one side of the insulator, and a grounding wire 2 extending from the tower pole to the ground surface The parallel gap protection device includes a lead-out electrode 3 that is connected to the conductive structure at the upper end of the insulator and is electrically connected to the ground wire at the same time, and also includes a mounting platform 4 located under the insulator and facing the lead-out electrode. The mounting platform 4 is fixed on the lower end of the insulator or the tower On the pole, the installation platform 4 includes a horizontal support plate 4a, and a control cylinder 4b arranged on the support plate 4a. The control cylinder 4b is a hollow structure, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com