Processing method for improving tenderness of pork chops through microbial fermentation

A technology of microbial fermentation and processing method is applied in the processing field of improving the tenderness of pork ribs, and can solve the problems of difficult chewing, heavy fishy smell, poor taste and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

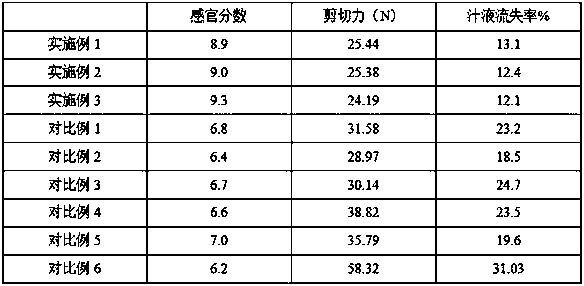

Examples

Embodiment 1

[0048] A processing method for improving the tenderness of pork ribs by microbial fermentation, comprising the following steps:

[0049] Step 1: Use a bone saw to cut the frozen pork ribs (1kg) into small pieces of pork ribs with a thickness of 1.5cm, a length of 6cm, and a width of 3cm, and then put them into ultrasonic cleaning with alkaline electrolytic water with a pH value of 8.0 (the mass ratio of small pork ribs to alkaline electrolyzed water is 1:3, and the temperature of alkaline electrolyzed water is 10°C during the whole treatment process), supplemented by ultrasonic treatment (the power of ultrasonic treatment is 200W, and intermittent Operation, each ultrasonic treatment time is 6 minutes, and the time interval between two ultrasonic treatments is 5 minutes), until the center temperature of the small pork ribs is 1~5°C, and the thawed pork ribs are obtained;

[0050] Step 2: Flatten the thawed pork ribs in step 1 at 1°C, and apply a vertical extrusion force of 50k...

Embodiment 2

[0055] A processing method for improving the tenderness of pork ribs by microbial fermentation, comprising the following steps:

[0056] Step 1: Use a bone saw to cut the frozen pork ribs (1kg) into small pieces of pork ribs with a thickness of 2.0cm, a length of 10cm, and a width of 5cm, and then put them into ultrasonic cleaning with alkaline electrolyzed water with a pH value of 9.5 (the mass ratio of small pork ribs to alkaline electrolyzed water is 1:4, and the temperature of alkaline electrolyzed water is 20°C during the whole treatment process), supplemented by ultrasonic treatment (the power of ultrasonic treatment is 300W, and intermittent Operation, each ultrasonic treatment time is 10min, and the time interval between two ultrasonic treatments is 5min), until the center temperature of the small pork ribs is 1~5°C, and the thawed pork ribs are obtained;

[0057] Step 2: Flatten the pork ribs thawed in step 1 at 5°C, and apply a vertical extrusion force of 60kg interm...

Embodiment 3

[0062] A processing method for improving the tenderness of pork ribs by microbial fermentation, comprising the following steps:

[0063]Step 1: Use a bone saw to cut the frozen pork ribs (1kg) into small pieces of pork ribs with a thickness of 1.75cm, a length of 8cm, and a width of 4cm, and then put them into ultrasonic cleaning with alkaline electrolyzed water with a pH value of 9.0 (the mass ratio of small pork ribs to alkaline electrolyzed water is 1:3.5, and the temperature of alkaline electrolyzed water is 15°C during the whole treatment process), supplemented by ultrasonic treatment (the power of ultrasonic treatment is 250W, and intermittent Operation, each ultrasonic treatment time is 8 minutes, and the time interval between two ultrasonic treatments is 5 minutes), until the center temperature of the small pork ribs is 1~5°C, and the thawed pork ribs are obtained;

[0064] Step 2: Flatten the thawed pork ribs in step 1 at 3°C, and apply a vertical extrusion force of 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com