CdS/ZnO composite piezoelectric photocatalyst and preparation method and application thereof

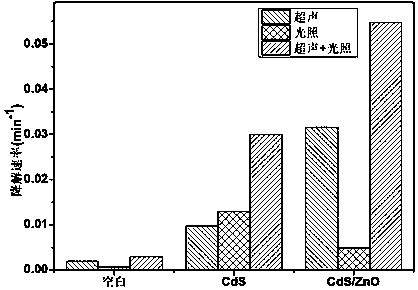

A catalyst and electro-optic technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as small piezoelectric coefficient, low energy utilization rate in nature, and serious recombination of photogenerated carriers. Achieve convenient operation, excellent piezoelectric photocatalytic activity, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

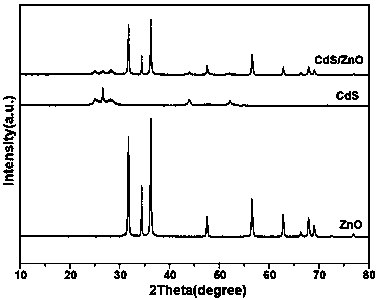

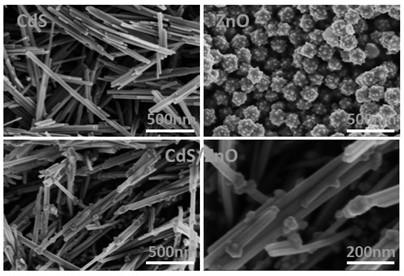

[0019] Add 20mL of 0.5M KOH alcohol solution dropwise to 10mL of 0.1M Zn(CH 3 CH 2 COO) 2 2H 2 O solution, after magnetic stirring for 30 min, the reaction solution was transferred to a 50ml polytetrafluoroethylene reactor, and reacted at 150°C for 24h. Cool to room temperature, centrifuge the sample, wash the sample with deionized water and ethanol, and dry it at 60 ° C for 12 hours to obtain ZnO nanorods.

Embodiment 2

[0021] Disperse 100 mg of ZnO nanorods in 40 mL of deionized water, add 96.5 mg of C 10 h 12 CdN 2 Na 2 o 8 ·XH 2 O, stirred magnetically for 30 min, and added 82.8 mg of C to the above solution at 80 °C 3 h 6 N 2 S, react at 80°C for 30min. Naturally cooled to room temperature, centrifuged, washed with deionized water and ethanol for several times, and vacuum-dried at 60° C. for 12 hours to obtain the CdS / ZnO composite.

Embodiment 3

[0023] Disperse 100 mg of ZnO nanorods in 40 mL of deionized aqueous solution, add 289.5 mg of C 10 h12 CdN 2 Na 2 o 8 ·XH 2 O, stirred magnetically for 30 min, and added 248.4 mg of C to the above solution at 80 °C 3 h 6 N 2 S, react at 80°C for 30min. Naturally cooled to room temperature, centrifuged, washed with deionized water and ethanol for several times, and vacuum-dried at 60° C. for 12 hours to obtain the CdS / ZnO composite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com