Polyethylene pipe bonding material and preparation method thereof

A technology of bonding materials and polyethylene pipes, applied in the direction of graft polymer adhesives, adhesives, adhesive types, etc., can solve the problem of poor infiltration coating effect, poor adhesive performance, and low bonding strength and other problems, to achieve the effects of good wetting and coating, good bonding performance and mechanical properties, and good film-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

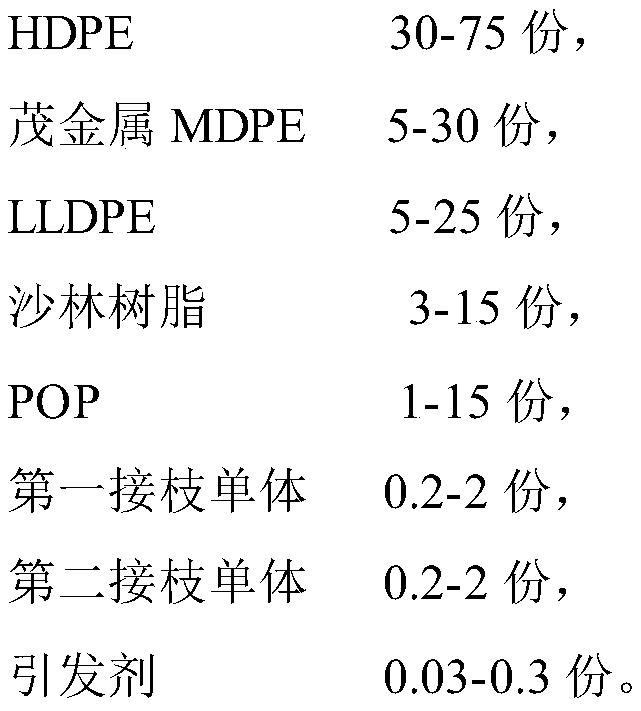

[0028] A polyethylene pipe bonding material, comprising the following components in parts by weight:

[0029]

[0030] A preparation method of the above-mentioned bonding material, comprising the steps of:

[0031] (1) Take each component according to parts by weight, place in a mixer and stir evenly to obtain a mixed material;

[0032] (2) Put the mixed material into the feed hopper of the extruder. The temperature of the extruder is: the temperature of the feeding section is 150°C, the temperature of the conveying and mixing section is 170°C, the temperature of the exhaust section is 180°C, and the temperature of the homogenization section is The temperature is 180°C, the temperature of the head is 200°C, and the polyethylene pipe bonding material is obtained by melting and extruding under the condition of 700 rpm, drawing, cooling, drying, granulating, and packaging.

Embodiment 2

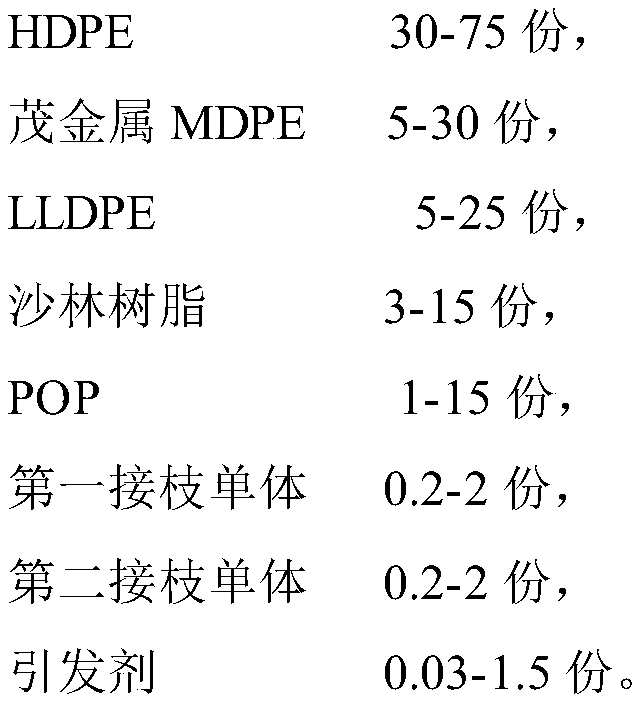

[0034] A polyethylene pipe bonding material, comprising the following components in parts by weight:

[0035]

[0036]

[0037] A preparation method of the above-mentioned bonding material, comprising the steps of:

[0038] (1) Take each component according to parts by weight, place in a mixer and stir evenly to obtain a mixed material;

[0039](2) Put the mixed material into the feed hopper of the extruder. The temperature of the extruder is: the temperature of the feeding section is 160°C, the temperature of the conveying and mixing section is 160°C, the temperature of the exhaust section is 190°C, and the temperature of the homogenization section is The temperature is 190°C, the head temperature is 190°C, melted and extruded under the condition of 900 rpm, and the polyethylene pipe bonding material is obtained after drawing, cooling, drying, granulating, and packaging.

Embodiment 3

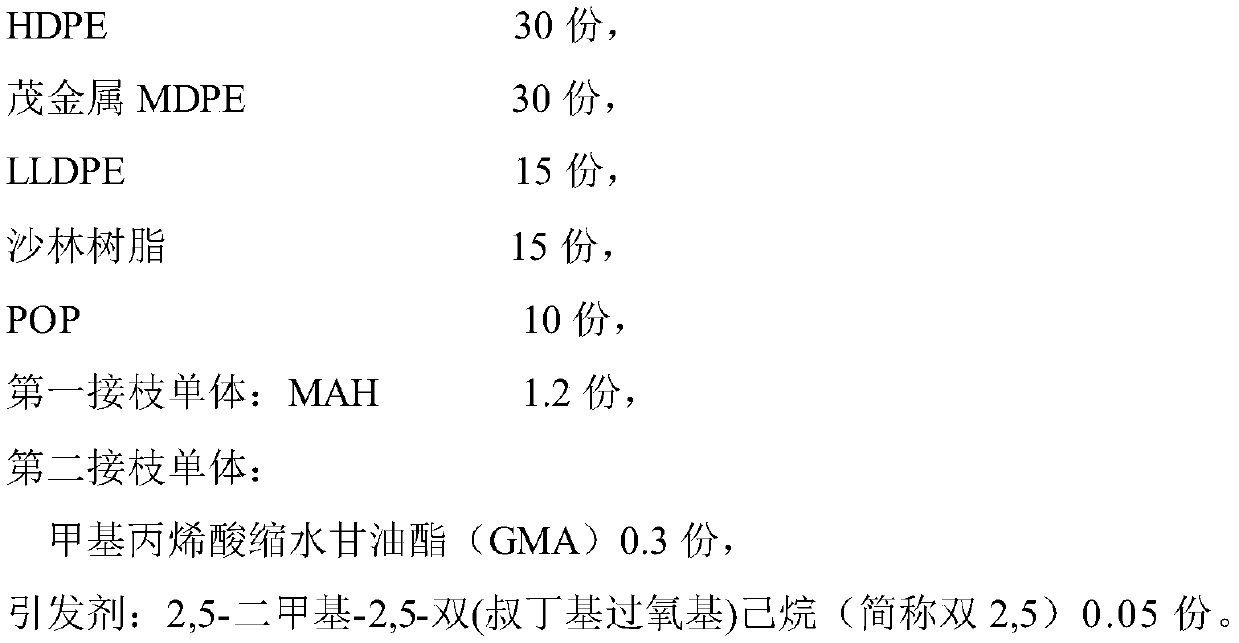

[0041] A polyethylene pipe bonding material, comprising the following components in parts by weight:

[0042]

[0043] A preparation method of the above-mentioned bonding material, comprising the steps of:

[0044] (1) Take each component according to parts by weight, place in a mixer and stir evenly to obtain a mixed material;

[0045] (2) Put the mixed material into the feed hopper of the extruder. The temperature of the extruder is: the temperature of the feeding section is 170°C, the temperature of the conveying and mixing section is 180°C, the temperature of the exhaust section is 190°C, and the temperature of the homogenization section is The temperature is 190°C, the temperature of the head is 200°C, and the polyethylene pipe bonding material is obtained by melting and extruding under the condition of 600 revolutions / min, drawing, cooling, drying, granulating, and packaging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com