Black plate light-colored fur leather product coating process

A wool leather and light-colored technology, which is applied in the field of finishing process of light-colored wool leather products on black boards, can solve the problems of high cost of dyeing wastewater treatment, affecting product qualification rate, and discoloration of the wool surface, and achieve blackness and migration resistance Optimum, saving water and chemicals, good whiteness of rough surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

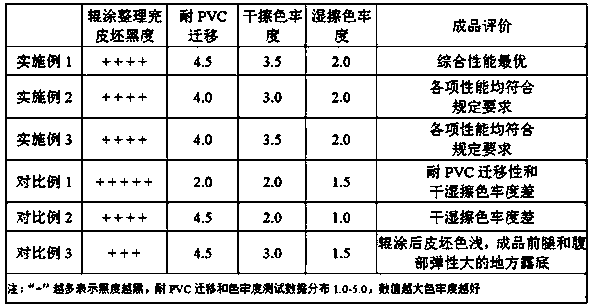

Examples

Embodiment 1

[0030] The finishing process of black board light-colored wool leather products includes the following specific operations:

[0031] 1) Horizontal stretcher: 25°C, 4 expansions;

[0032] 2) Roller coating:

[0033] Penetrant Metoxi: 400 parts by weight, penetrating leveling agent 0240: 600 parts by weight, dye water 5915: 150 parts by weight, ultrafine pigment paste 5450: 100 parts by weight, BASF black dye water: 150 parts by weight;

[0034] Prepare the above chemical materials into a solution, roll the 24L roll of the roller coater, roll once, and roll the 32L roll, roll 3 times;

[0035] 3) Drying: Each roll needs to be dried once, the drying temperature is 50-70°C, and the board is placed on the board;

[0036] 4) Water spray: spray water from the water spray machine, drain water 2 times, and let it stand for 30 minutes;

[0037] 5) Rotating cage: 20min;

Embodiment 2

[0057] The difference with Example 1 is: the chemical material that roll coating adopts comprises the following components by weight: 300 parts of penetrating agent Metoxi, 700 parts of penetrating and leveling agent 0240, 100 parts of dye water 5915, superfine particle pigment 80 parts of paste 5450, 200 parts of BASF black dye water.

Embodiment 3

[0059] The difference with Example 1 is: the chemical material that roll coating adopts comprises the following components by weight: 500 parts of penetrating agent Metoxi, 500 parts of penetrating and leveling agent 0240, 200 parts of dye water 5915, superfine particle pigment 120 parts of ointment 5450, 100 parts of BASF black dye water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com