Downhole electronically controlled water plugging and production increase switch

A switch and electronic control technology, which is applied in the production fluid, wellbore/well components, wellbore/well valve device, etc., can solve the problems of heavy weight, large diameter, adverse effects of operation progress, etc., and improve construction efficiency. , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

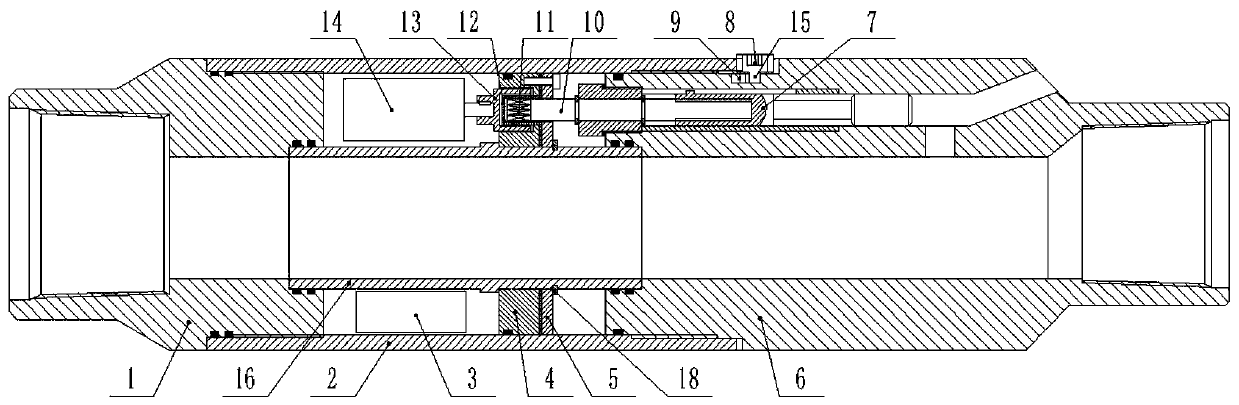

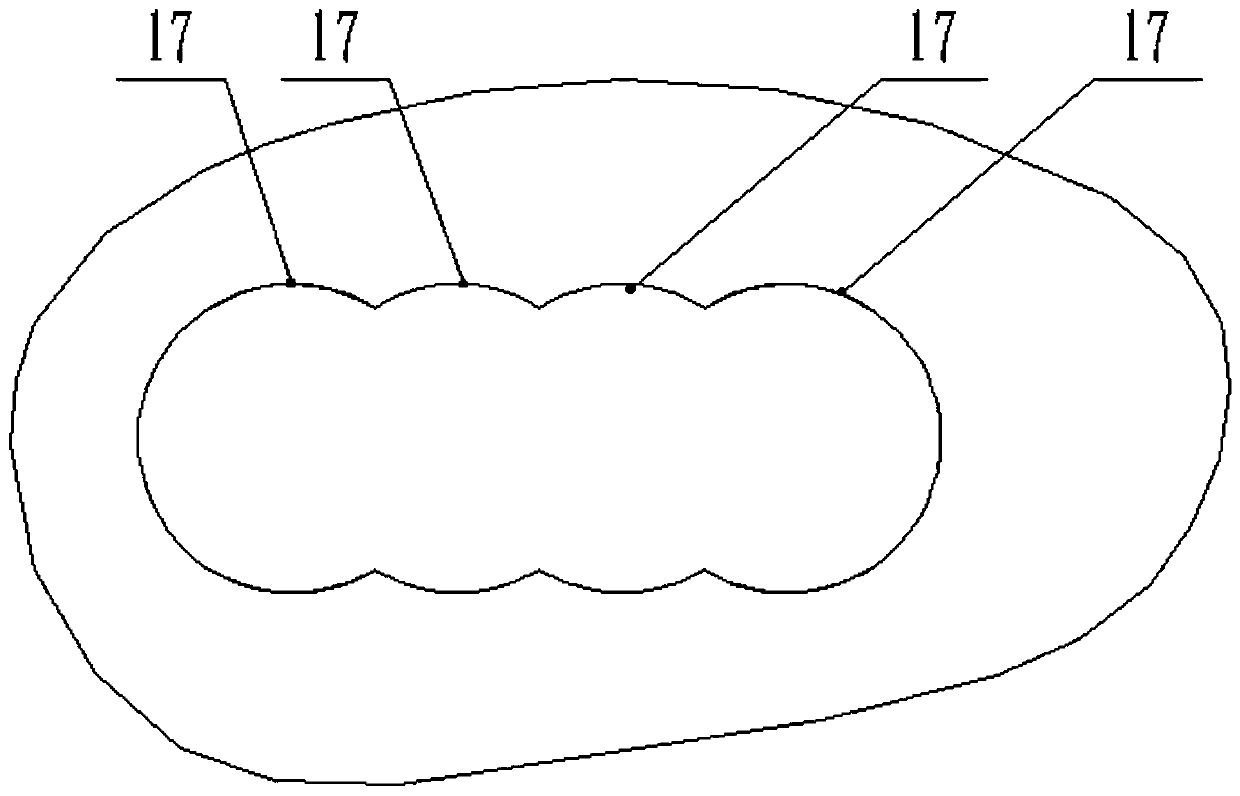

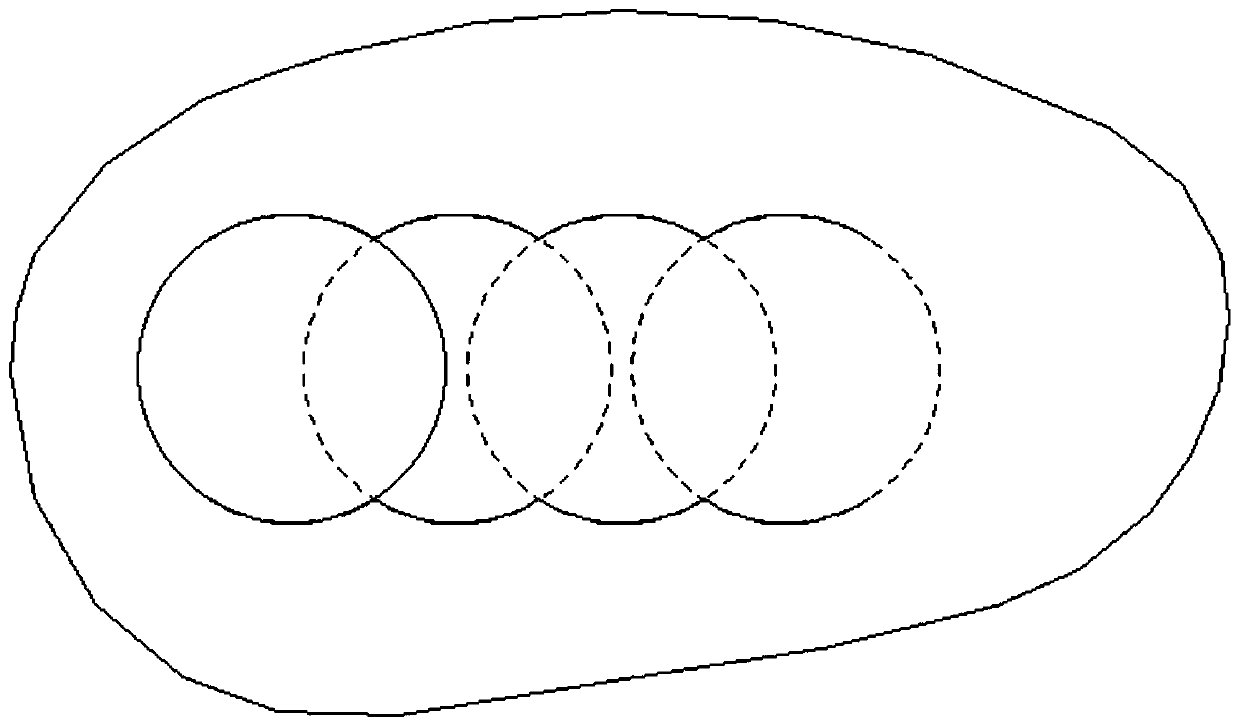

[0019] This embodiment includes an upper joint 1, an outer cylinder 2, a lower joint 6, a central pipe 16, a power module 3, a motor 14, and a valve mechanism. The upper joint 1 and the lower joint 6 are respectively threaded to the upper and lower ends of the outer cylinder 2 and connected The upper and lower ends of the central tube 16 are respectively inserted on the upper joint 1 and the lower joint 6 and the plug joints are sealed by the sealing ring. The valve mechanism is installed on the lower joint 6, and the power module 3 and the motor 14 are installed on the outer cylinder. 2 and the central tube 16 in the annular closed space, the valve mechanism includes a screw 10 and a valve stem 7, the screw 10 and the valve stem 7 are connected through a threaded pair, and the power module 3 supplies power to the motor 14, The lead screw 10 rotates under the drive of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com