Method for detecting tin element in ore

An element and ore technology, applied in the field of fast and accurate detection, can solve the problems of salt accumulation in ICP atomizer and rectangular tube, affecting the accuracy and stability of test results, and inability to accurately detect other elements, so as to ensure the fog Improve the efficiency and sensitivity of the method, improve the accuracy of the method, and eliminate the effect of matrix interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

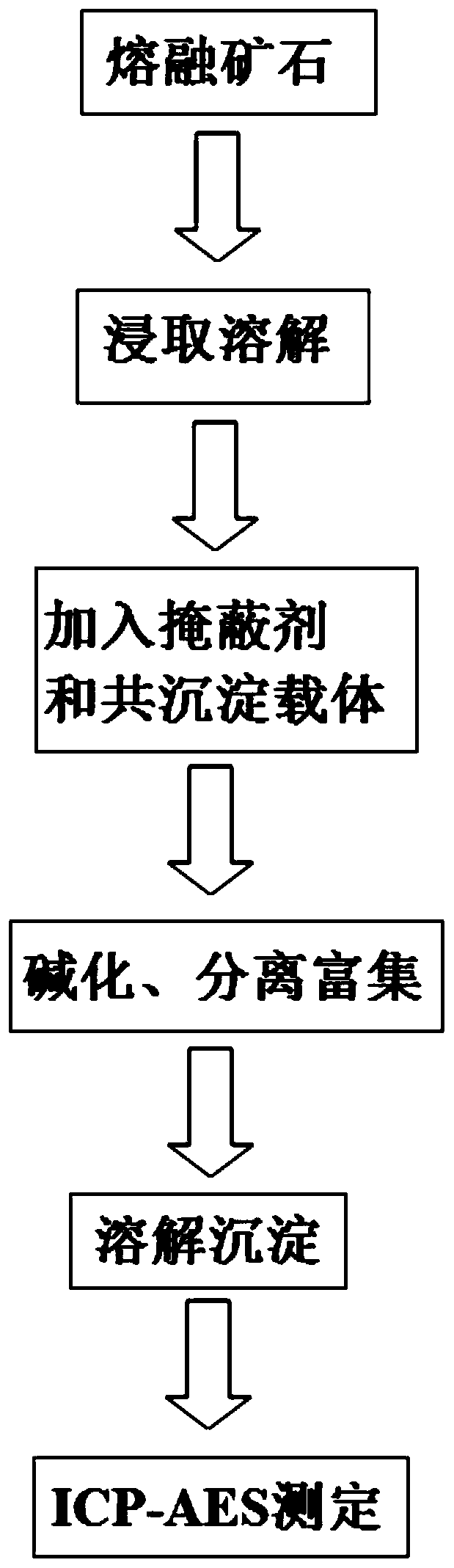

[0030] A kind of method of detecting tin element in ore of the present invention, flow process is as figure 1 As shown, the steps are as follows:

[0031] (1) Molten ore:

[0032] Accurately weigh 0.1g (accurate to 0.0001g) ore standard samples GBW07281, GBW07241, GBW07238, put them into 3 parts of high-alumina crucibles with 3g of sodium peroxide added respectively, stir well and then cover with 1g of sodium peroxide, then place at 700 ℃ for 10 minutes in a muffle furnace.

[0033] (2) Leaching and dissolving:

[0034] Take out the crucible and put it into a 300mL beaker filled with 100mL water to let it cool slightly. After cooling, quickly add 25mL hydrochloric acid to wash out the crucible. First leaching with water and then adding acid can prevent the alkali-dissolved sample from directly reacting too violently with the acid and causing splashing.

[0035] (3) Add masking agent and co-precipitation carrier:

[0036] Add 30mL of 10% EDTA solution as a masking agent, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com