Method for preparing sample observing orientation of crystal grains in Al metallization layer of IGBT chip

A sample preparation and metallization technology, which is applied in the preparation of test samples, material analysis by wave/particle radiation, sampling, etc., can solve the problem that the Al metallization layer cannot be observed, the Al metallization layer becomes rough, and cannot be obtained. Problems such as poor crystal orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

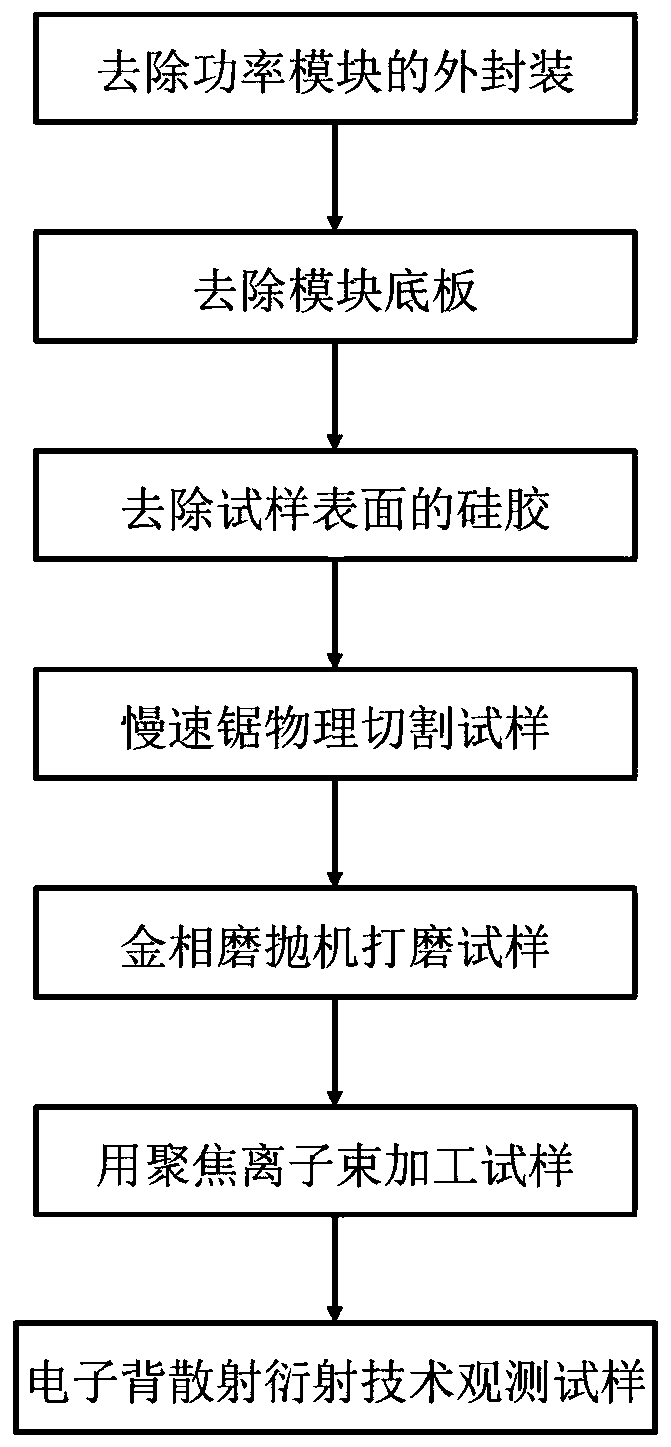

[0034] A method for preparing a sample for observing the grain direction in the Al metallization of an IGBT chip, characterized in that it comprises the following steps:

[0035] A) Remove the outer package of the high-power IGBT module by machining;

[0036] B) Set the temperature of the constant-temperature heating platform to 250°C, place the high-power IGBT module on the constant-temperature heating platform, and keep the bottom plate of the power module in contact with the constant-temperature heating platform for about 30 seconds, until the solder layer between the copper-clad ceramic substrate and the bottom plate is melted, Remove the bottom plate of the module, and the module structure at this time only leaves the high-power IGBT chip layer and the copper-clad ceramic substrate;

[0037] C) soaking the remaining structure of the high-power IGBT module in step B) in a silica gel remover for 12 hours to remove the silica gel on the surface of the IGBT chip;

[0038] D)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com