Automatic layout method of Simulink

An automatic layout and layout technology, applied in the fields of instrumentation, calculation, electrical and digital data processing, etc., can solve the problems of unreliable simulation results, difficulty in ensuring the execution sequence of modules, cumbersome and other problems, so as to minimize the number, optimize the layout, and avoid logic errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

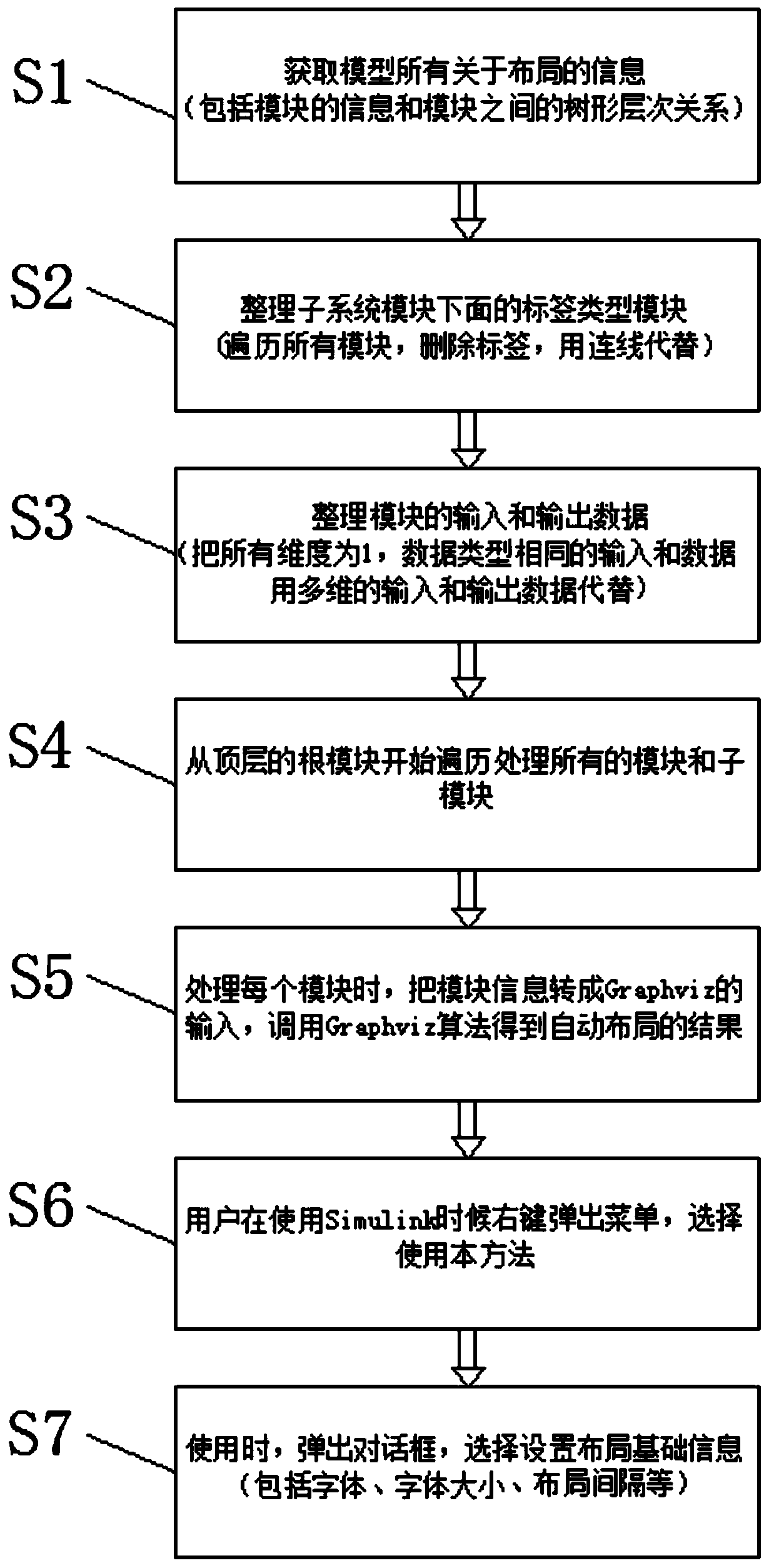

[0036] see Figure 1-4 , an automatic layout method of Simulink, including the following steps:

[0037] S1: Obtain all information about the layout of the model, including module information and tree-like hierarchical relationships between modules. Module information includes position, height, width, module display text, input data type, input number, output data type, output number, etc.

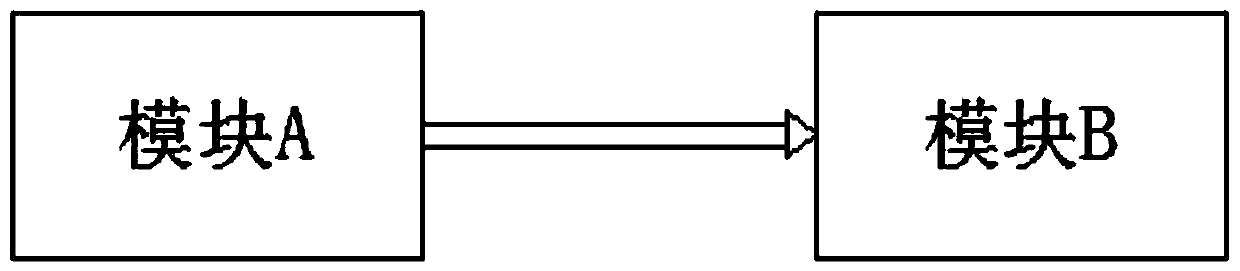

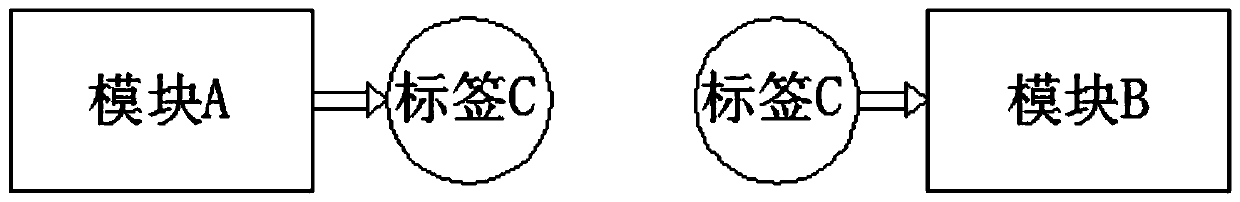

[0038] S2: Organize the label type modules under the subsystem module. If there is a local label module, delete the local label module and connect it with a line. If there is a non-local label module, first traverse the module tree of the entire model to find all non-local label modules (Scoped or Global type) with the same name, and then divide them into two groups according to the read-write type. There must be only one write type, and there can be multip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com