High-power traction auxiliary converter

A technology for auxiliary converters and traction converters, applied in the field of converters, can solve the problems of large size, large installation space, inconvenient maintenance and other problems, and achieve simple and efficient assembly and production, high integration, and reduced The effect of small electrical disturbances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

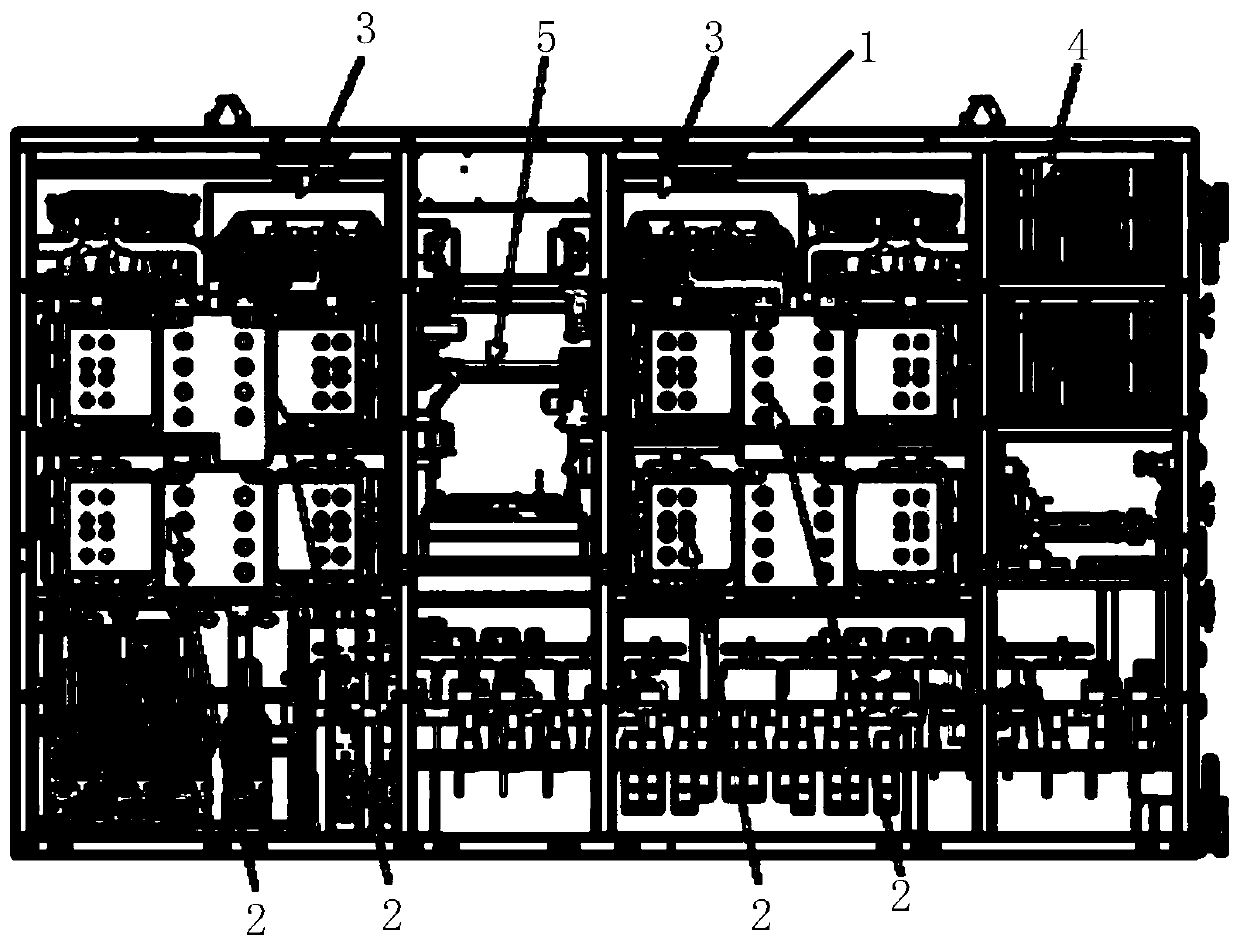

[0033] see figure 1 As shown, the high-power traction auxiliary converter provided by the present invention includes: a cabinet body 1, and four sets of traction converters 2, two sets of auxiliary converters 3, a control unit 4 and a cooling unit 5 are arranged in the cabinet body 1 Two sets of traction converters 2 and one set of auxiliary converters 3 are arranged on both sides of the cooling unit 5; the control unit 4 is located on the upper right of the cabinet body 1, and the cooling unit 5 controls the traction converters 2 and auxiliary converters at the same time. flow device 3 for cooling.

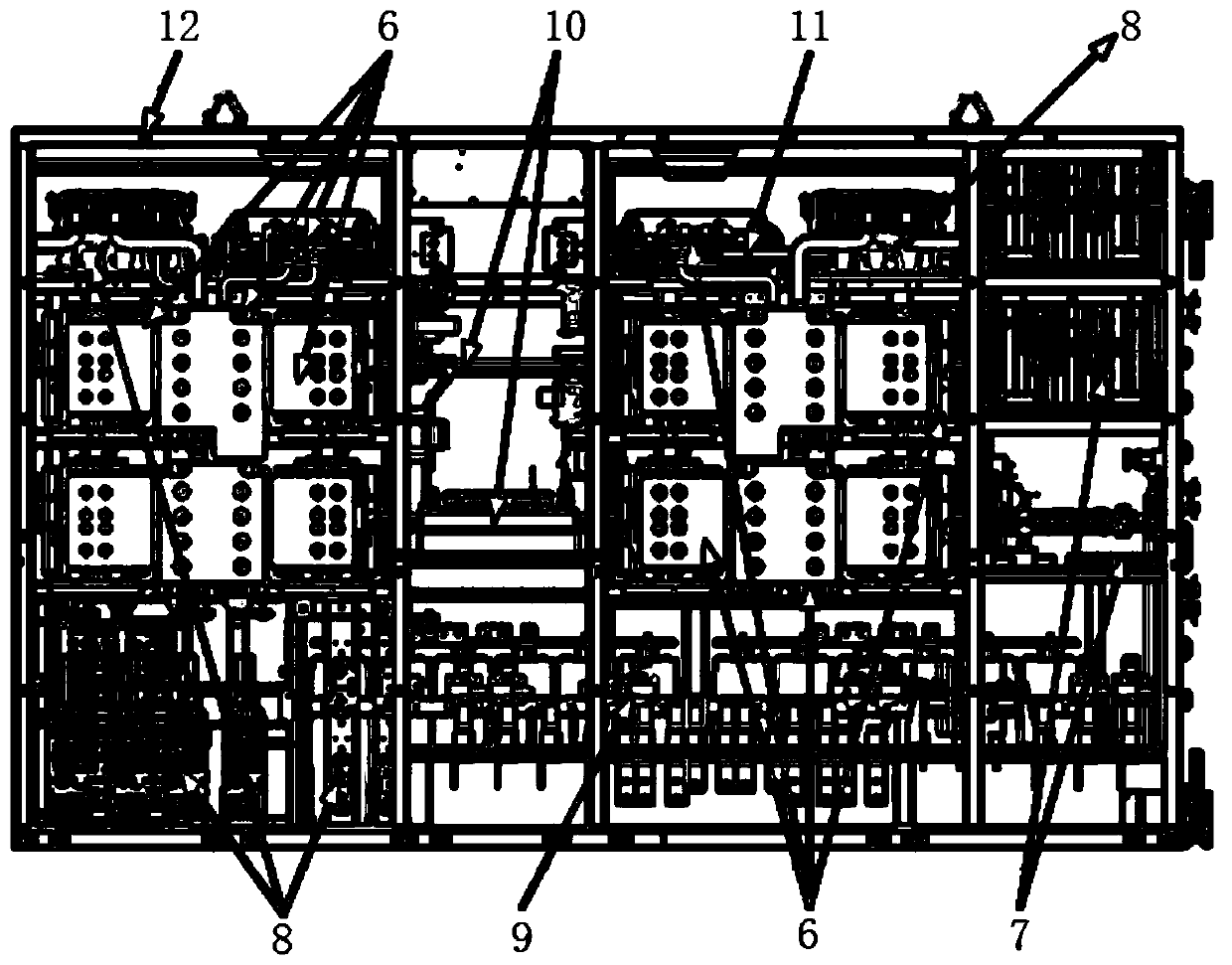

[0034] Further, the cabinet includes power modules and capacitor components 6, low-voltage electrical components 7, switch electrical components 8, sensor components 9, cooling components 10, copper bar components 11, box components 12, and low-voltage line components. High voltage auxiliary components and door components.

[0035] Further, the power module and capacitor assemb...

Embodiment 2

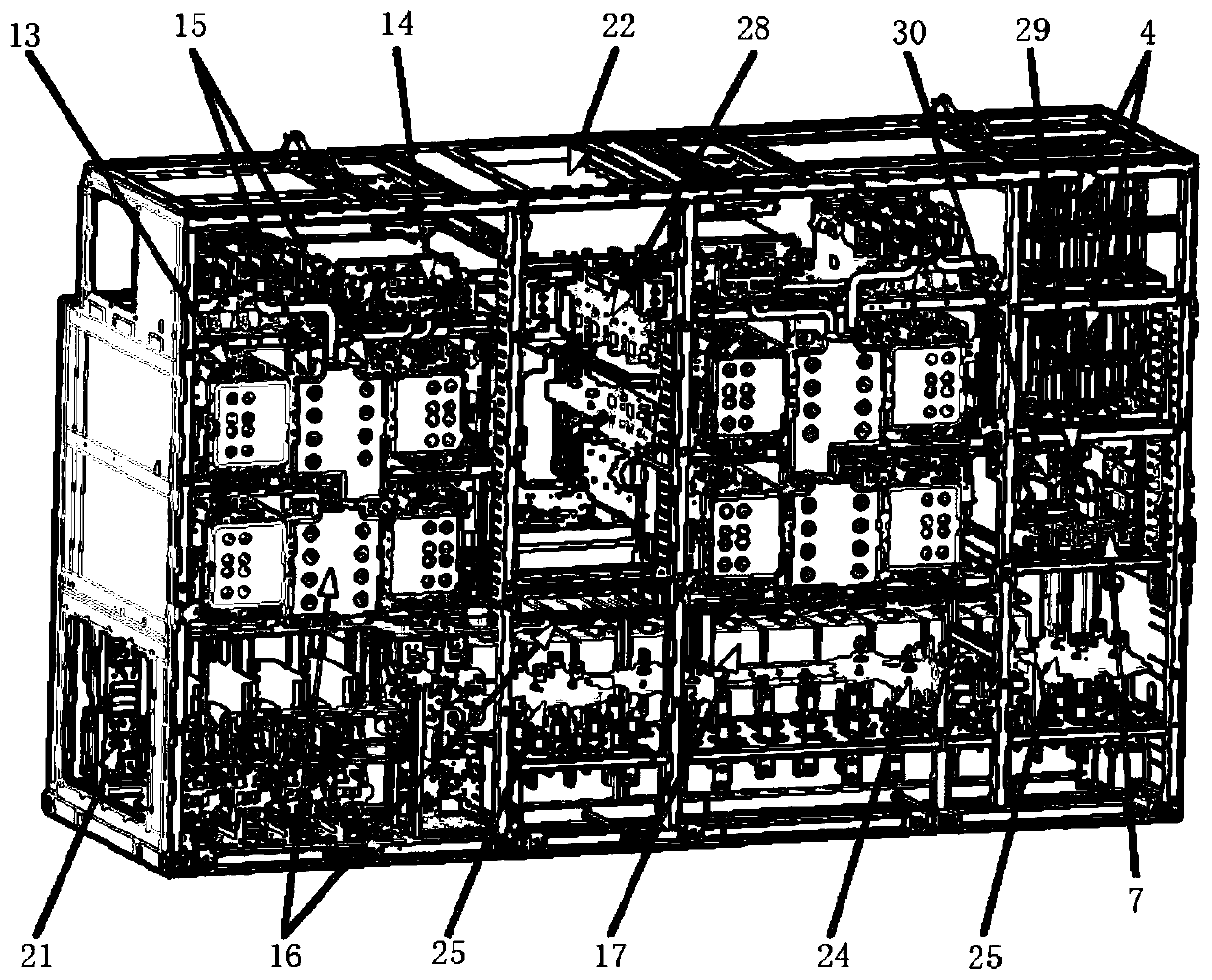

[0054] The present invention also provides a high-power traction auxiliary converter, see figure 1 As shown, it mainly includes ten kinds of components, see Figure 2-3 As shown, the power module and capacitor assembly 6 (including traction power module 13, auxiliary inverter power module 14, intermediate support capacitor 15, secondary filter capacitor 17, composite busbar 16 and other main components), low-voltage Control unit, relay, voltage transformer, current transformer, filter and other main components), switching electrical components 8 (mainly including main contactor 18, pre-charging contactor 20, isolating switch 19, pre-charging resistor 21, chronic discharge resistor , chopper resistance 22 and other main components), sensor assembly 9 (including current sensor and voltage sensor 28, pressure sensor 29, temperature sensor 30, etc. of input and output ground loops and intermediate loops), cooling assembly 10 (including temperature control device 33 , resistance w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com