Amino acid complementary compound nutritious assorted grain porridge and preparation method thereof

A complementary amino acid technology, applied in the functions of food ingredients, oligosaccharide-containing food ingredients, food science, etc., can solve the problems of insufficient absorption of protein in eight-treasure porridge, the reduction of nutritional value of eight-treasure porridge, and the reduction of the value of eight-treasure porridge, so as to reduce raw materials Effect of soaking process, shortening cooking and sterilization time, and improving nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing amino acid complementary compound miscellaneous grain nutritional eight-treasure porridge, the raw materials include main ingredients and auxiliary materials,

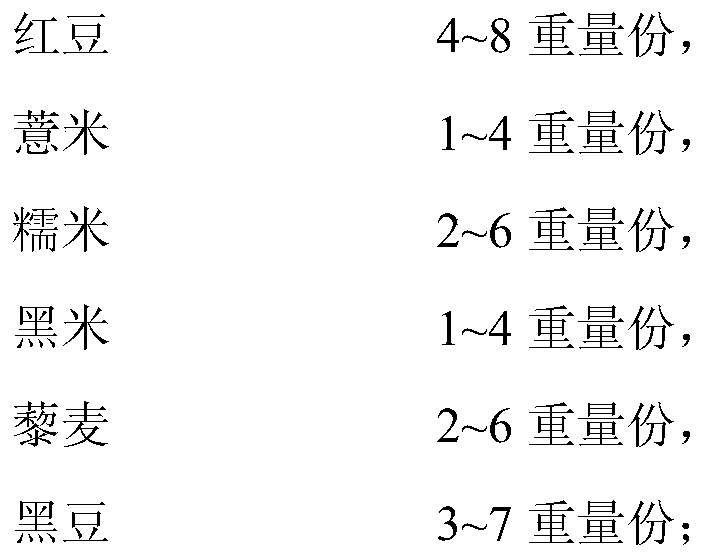

[0027] The main ingredient ratio includes 4-8 parts by weight of red beans, 1-4 parts by weight of barley, 2-6 parts by weight of glutinous rice, 1-4 parts by weight of black rice, 2-6 parts by weight of quinoa, 3 parts by weight of ~7 parts by weight of black beans;

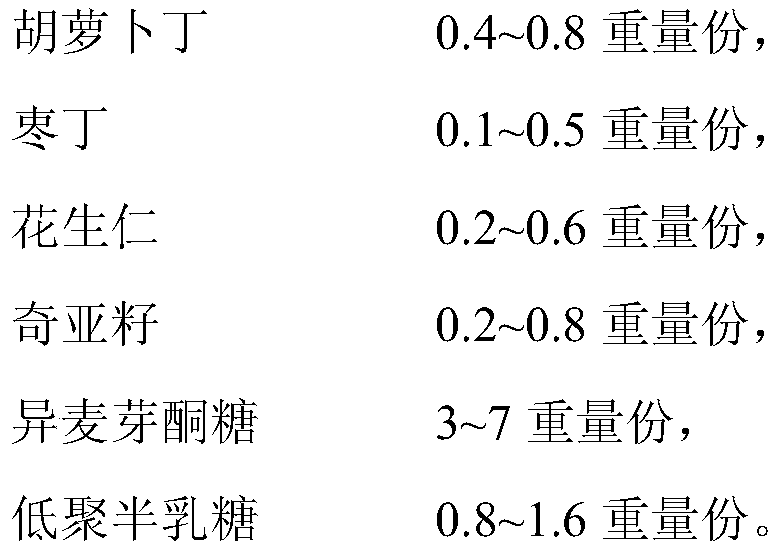

[0028] Described auxiliary material proportioning comprises following raw material by weight:

[0029] 0.4 to 0.8 parts by weight of diced carrots, 0.1 to 0.5 parts by weight of diced carrots, 0.2 to 0.6 parts by weight of peanut kernels, 0.2 to 0.8 parts by weight of chia seeds, 3 to 7 parts by weight of isomaltulose, 0.8 to 0.6 parts by weight of 1.6 parts by weight of galactooligosaccharides;

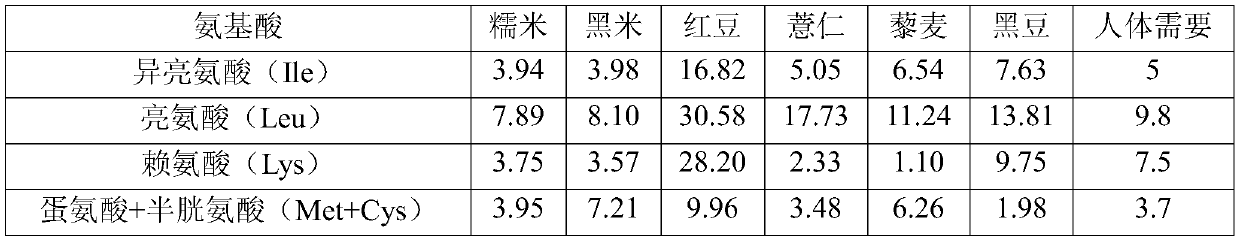

[0030] During the preparation process, the content of all essential amino acids in red beans, barley, glutinous rice, black ric...

Embodiment 2

[0039] A method for preparing amino acid complementary compound miscellaneous grain nutritional eight-treasure porridge. During the preparation process, the content of all essential amino acids in red beans, barley, glutinous rice, black rice, quinoa, and black beans in the main ingredients is firstly measured, and then based on the ratio of raw materials, weigh enough The raw materials of the FAO / WHO scoring model are specifically red beans of 8 parts by weight, barley of job's tears of 3 parts by weight, glutinous rice of 6 parts by weight, black rice of 3.6 parts by weight, quinoa of 5.2 parts by weight, black beans of 5.6 parts by weight; 0.4 parts by weight Part of carrot diced, 0.2 parts by weight of diced diced, 0.6 parts by weight of peanut kernels, 0.8 parts by weight of chia seeds, 5.6 parts by weight of isomaltulose, 1.4 parts by weight of galacto-oligosaccharides; Clean and filter water, then transport the raw materials to the packaging container, add solid raw mate...

Embodiment 3

[0041]A method for preparing amino acid complementary compound miscellaneous grain nutritional eight-treasure porridge. During the preparation process, the content of all essential amino acids in red beans, barley, glutinous rice, black rice, quinoa, and black beans in the main ingredients is firstly measured, and then based on the ratio of raw materials, weigh enough The raw materials of the FAO / WHO scoring model are specifically 4 parts by weight of red beans, 1 part by weight of barley, 2 parts by weight of glutinous rice, 1 part by weight of black rice, 2 parts by weight of quinoa, and 3 parts by weight of black beans; 0.4 parts by weight Part of carrot diced, 0.1 weight part of diced diced, 0.2 weight part of peanut kernels, 0.2 weight part of chia seeds, 3 weight parts of isomaltulose, 0.8 weight part of galacto-oligosaccharide; Clean and filter water, then transport the raw materials to the packaging container, add solid raw materials and drinking water into the packagin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com