Cerium-doped zinc phosphate material, preparation method thereof, anti-corrosion coating containing same

An anti-corrosion coating and cerium doping technology are applied in the field of cerium doped zinc phosphate materials and their preparation, which can solve the problems of step-by-step precipitation, high temperature required for preparation process, large amount of waste water discharge, etc. Wide, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of anticorrosion coating of present embodiment, its preparation method is as follows:

[0036] (1) Preparation of cerium-doped zinc phosphate material

[0037] Take 80mL of 0.15mol / L ZnSO 4 ·7H 2 O and 20mL of 0.15mol / L CeCl 3 After mixing evenly, add 48 mL of 0.25 mol / L Na 3 PO 4 12H 2 O, control the rate of addition to a constant rate of 0.5mL / min, keep stirring for 60min, and age the resulting precipitate for 24h. Wash 5 times with ethanol and distilled water, and centrifuge at a speed of 6000 rpm, dry the obtained precipitate at 96°C for 48 hours, take the dried precipitate and grind it into a powder in a mortar to obtain flake Ce 3+ Doped nano-zinc phosphate product, do A component.

[0038] 3ZnSO 4 ·7H 2 O+2Na 3 PO 4 12H 2 O=Zn 3 (PO 4 ) 2 +3Na 2 SO 4 +45H 2 o

[0039] (2) Preparation of resin matrix

[0040] Take 6g of ethylene glycol monobutyl ether and dissolve 15g of water-based epoxy resin (E51). After it is completely dissolved, ad...

Embodiment 2

[0045] A kind of anticorrosion coating of present embodiment, its preparation method is as follows:

[0046] (1) Preparation of cerium-doped zinc phosphate material

[0047] Take 85mL of 0.15mol / L ZnSO 4 ·7H 2 O and 15mL of 0.15mol / L CeCl 3 After mixing evenly, add 46 mL of 0.25 mol / L Na 3 PO 4 12H 2O, control the rate of addition to a constant rate of 0.5mL / min, keep stirring for 60min, and age the resulting precipitate for 24h. Wash 5 times with ethanol and distilled water, and centrifuge at a speed of 6000 rpm, dry the obtained precipitate at 96°C for 48 hours, take the dried precipitate and grind it into a powder in a mortar to obtain flake Ce 3+ Doped nano-zinc phosphate product, do A component.

[0048] 3ZnSO 4 ·7H 2 O+2Na 3 PO 4 12H 2 O=Zn 3 (PO 4 ) 2 +3Na 2 SO 4 +45H 2 o

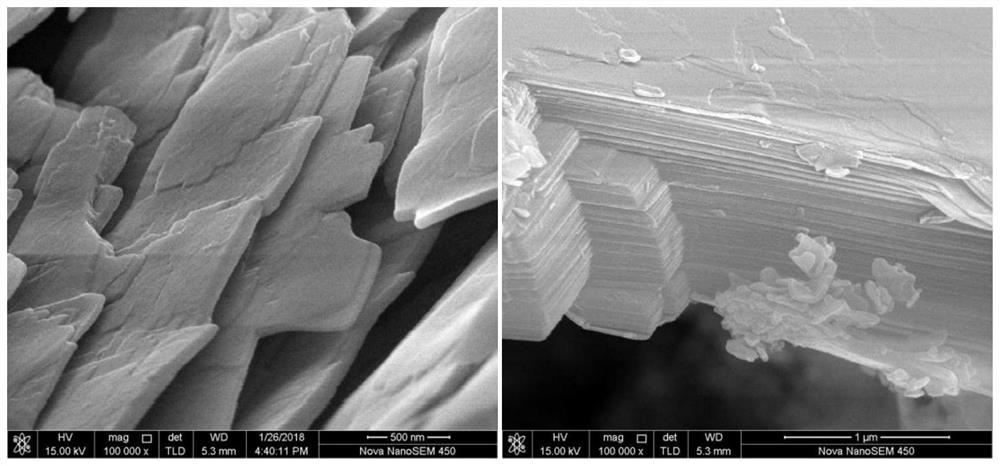

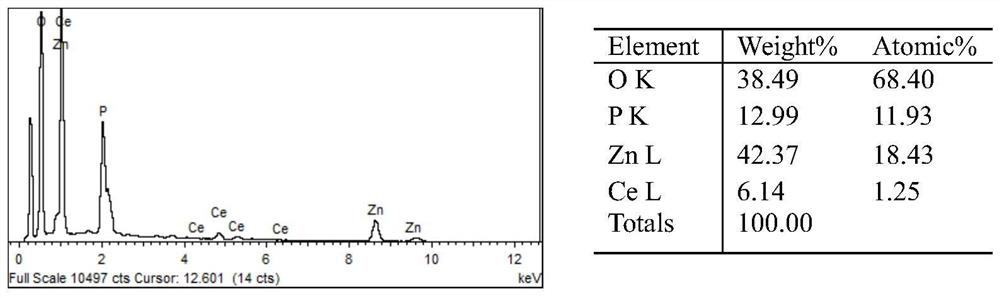

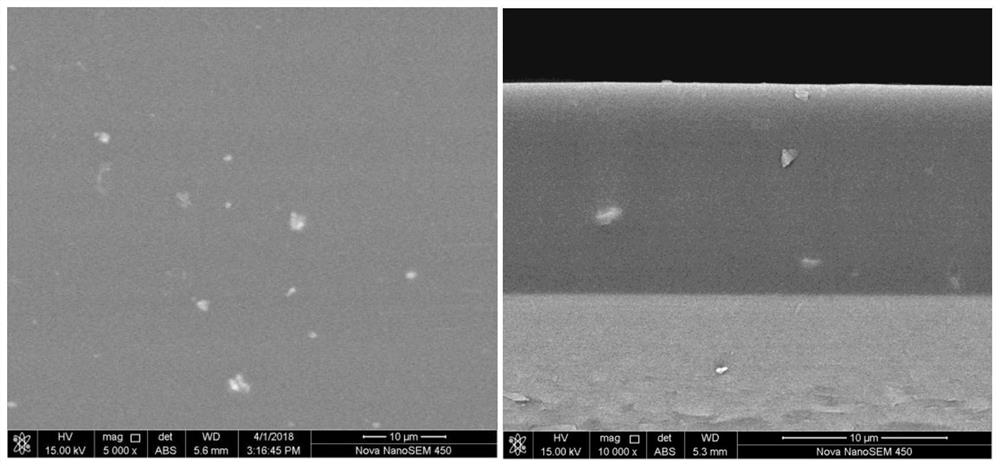

[0049] The field emission scanning electron microscope picture of the cerium-doped nano-zinc phosphate product prepared in embodiment 2 is as follows figure 1 As shown, it can be ...

Embodiment 3

[0057] A kind of anticorrosion coating of present embodiment, its preparation method is as follows:

[0058] (1) Preparation of cerium-doped zinc phosphate material

[0059] Take 85mL of 0.15mol / L ZnSO 4 ·7H 2 O and 15mL of 0.15mol / L CeCl 3 After mixing evenly, add 46 mL of 0.25 mol / L Na 3 PO 4 12H 2 O, control the rate of addition to a constant rate of 0.5mL / min, keep stirring for 60min, and age the resulting precipitate for 24h. Wash 5 times with ethanol and distilled water, and centrifuge at a speed of 6000 rpm, dry the obtained precipitate at 96°C for 48 hours, take the dried precipitate and grind it into a powder in a mortar to obtain flake Ce 3+ Doped nano-zinc phosphate product, do A component.

[0060] 3ZnSO 4 ·7H 2 O+2Na 3 PO 4 12H 2 O=Zn 3 (PO 4 ) 2 +3Na 2 SO 4 +45H 2 o

[0061] (2) Preparation of resin matrix

[0062] Take 6g of isopropanol and n-butanol blending agent (mass ratio of isopropanol and n-butanol=4:1) to dissolve 25g of water-based e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com