Jet aeration arm and integrated jet aerator containing jet aeration arms

A jet aeration and aeration technology, applied in the field of water treatment, can solve the problems of low mass transfer efficiency and power efficiency, limited gas-liquid two-phase contact area, and low oxygen mass transfer efficiency, so as to improve the efficiency of sewage treatment, Improve mass transfer efficiency and power efficiency, and enhance the effect of turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

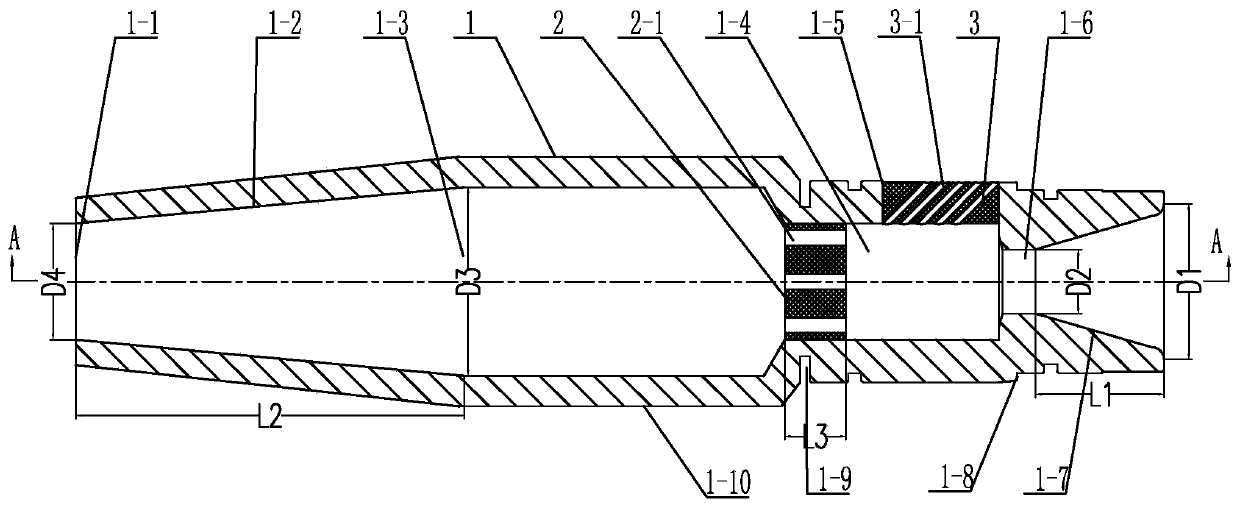

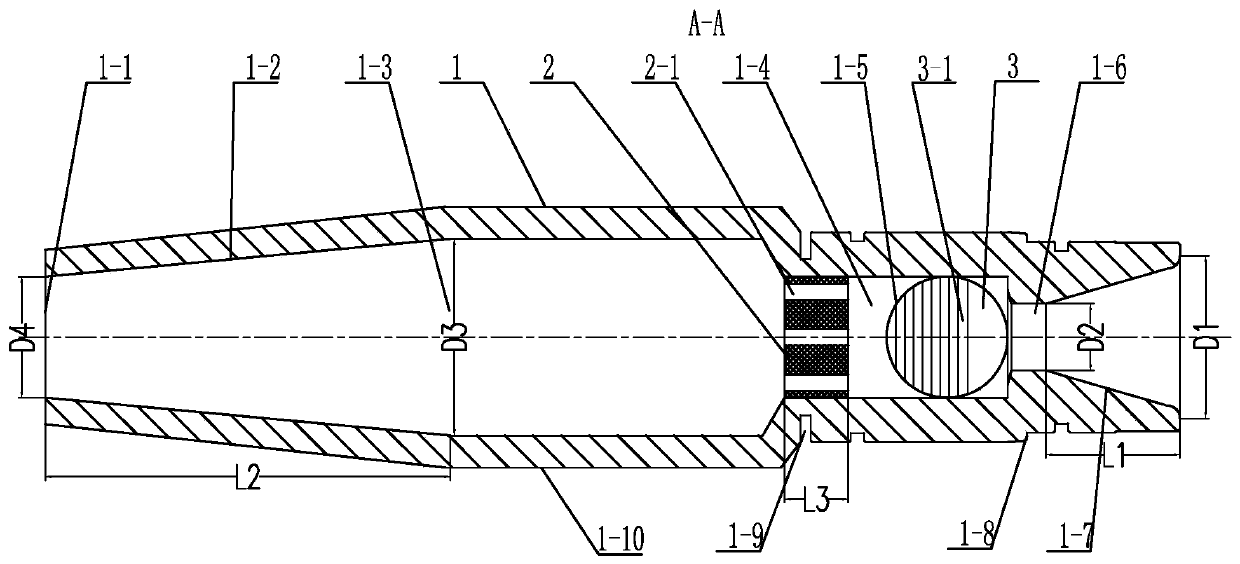

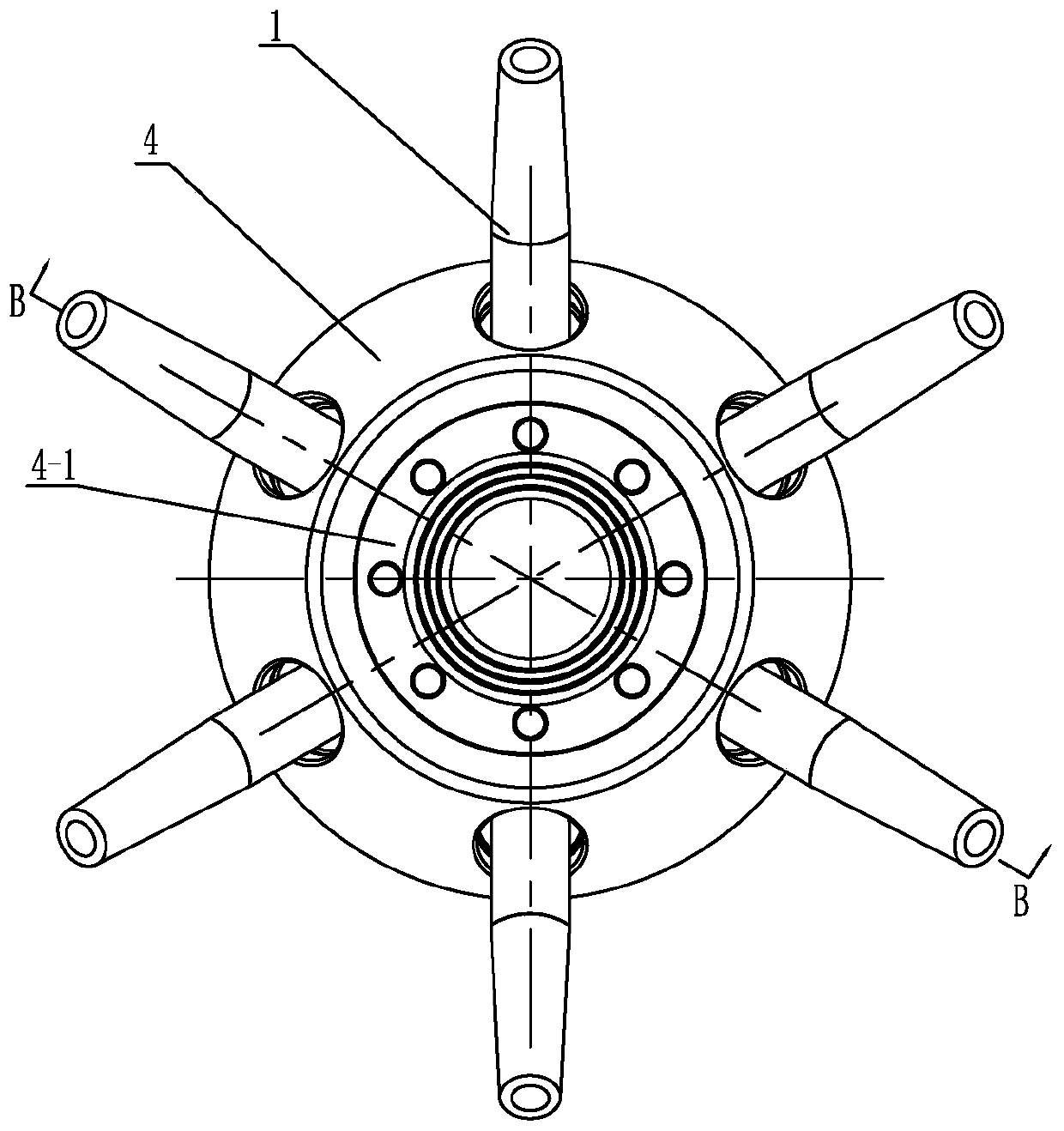

[0015] See figure 1 , 2 As shown, the jet aeration arm of the present invention includes an arm body 1-10 with a cavity inside, and the rear portion of the arm body 1-10 has a water inlet hole 1-7 and an arm body 1-10 for passing into the liquid phase. The 10 sides are used to pass into the air inlet 1-5 of the gas phase, and the arm body 1-10 cavity is provided with a primary nozzle 1-6 between the water inlet 1-7 and the air inlet 1-5, and the water inlet 1-7 has a first tapering part and transitions to a first-stage nozzle 1-6, and the ratio of the axial length to the diameter difference of the first tapering part of the water inlet hole 1-7 is 0.8 to 1.6, that is, the water inlet hole 1-7 The axial length L1 / major diameter D1-minor diameter D2, the axial length and diameter difference ratio of the first tapering part can also be 1.0-1.4, because the liquid phase can make the aperture of the water inlet hole 1-7 gradually along the flow direction Decrease, so that the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com