Oil and gas well workover working fluid

A technology for working fluids and oil and gas wells, applied in the direction of drilling compositions, chemical instruments and methods, etc., which can solve problems such as low bottom hole pressure, reduced production, reservoir damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

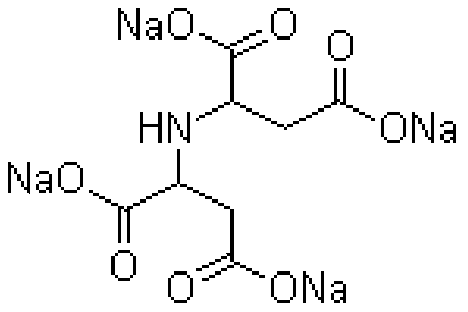

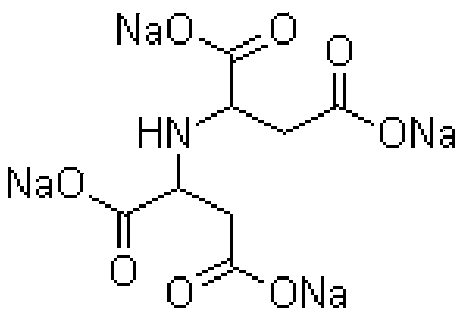

[0022] The oil and gas well workover working fluid has the following mass content of each component: 0.5% of polymer, 0.5% of oil-soluble resin, 0.4% of sodium iminodisuccinic acid, and the balance of brine base fluid.

[0023] The brine base liquid is a mixture of calcium bromide and zinc bromide (1:1.2). The concentration of the brine base liquid is 70-80%. The polymer is hydroxyethyl cellulose. Described oil-soluble resin is sodium abietate, melamine formaldehyde resin. The sodium iminodisuccinate is tetrasodium iminodisuccinate.

Embodiment 2

[0025] The mass content of each component of the workover fluid for oil and gas wells is: 1% of polymer, 1% of oil-soluble resin, 0.8% of iminodisuccinic acid sodium salt, and the balance of brine base fluid.

[0026] The brine base liquid is a mixture of calcium bromide and zinc bromide (1:1.2). The concentration of the brine base liquid is 70-80%. The polymer is hydroxyethyl cellulose. Described oil-soluble resin is sodium abietate, melamine formaldehyde resin. The sodium iminodisuccinate is tetrasodium iminodisuccinate.

Embodiment 3

[0028] The oil and gas well workover working fluid has the following mass content of each component: 0.5% of polymer, 0.5% of oil-soluble resin, 0.8% of iminodisuccinic acid sodium salt, and the balance of brine base fluid.

[0029] The brine base liquid is a mixture of calcium bromide and zinc bromide (1:1.2). The concentration of the brine base liquid is 70-80%. The polymer is hydroxyethyl cellulose. Described oil-soluble resin is sodium abietate, melamine formaldehyde resin. The sodium iminodisuccinate is tetrasodium iminodisuccinate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com