An X-band metamaterial wave-absorbing sensor

A sensor and metamaterial technology, which is applied in the direction of material analysis using microwave means, material analysis through electromagnetic means, and material capacitance, can solve the problems of large size and low sensitivity of metamaterial wave-absorbing sensors, and achieve reduced size and improved Sensitivity, effect of increasing volume ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to clearly illustrate the present invention, the present invention will be further described below with reference to the accompanying drawings.

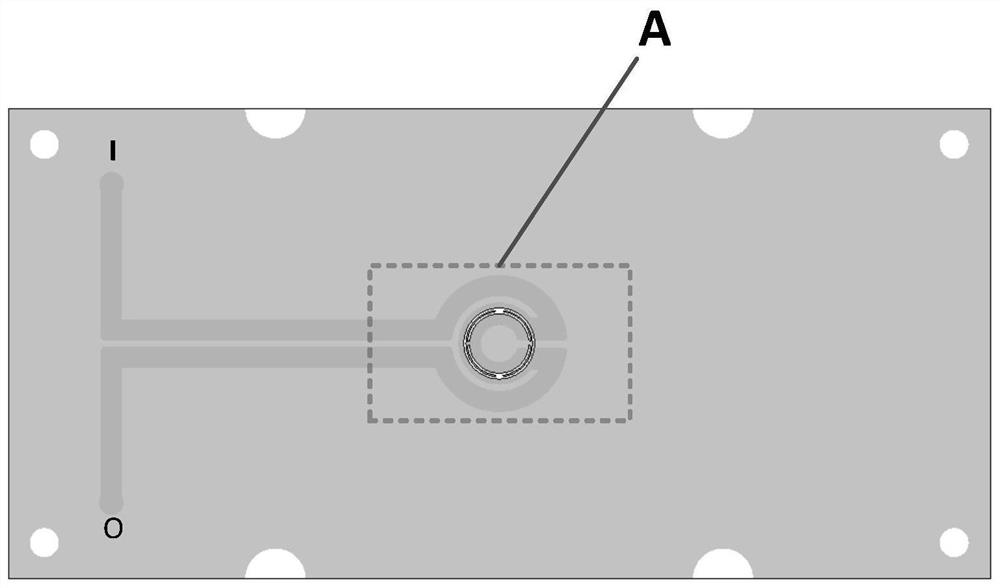

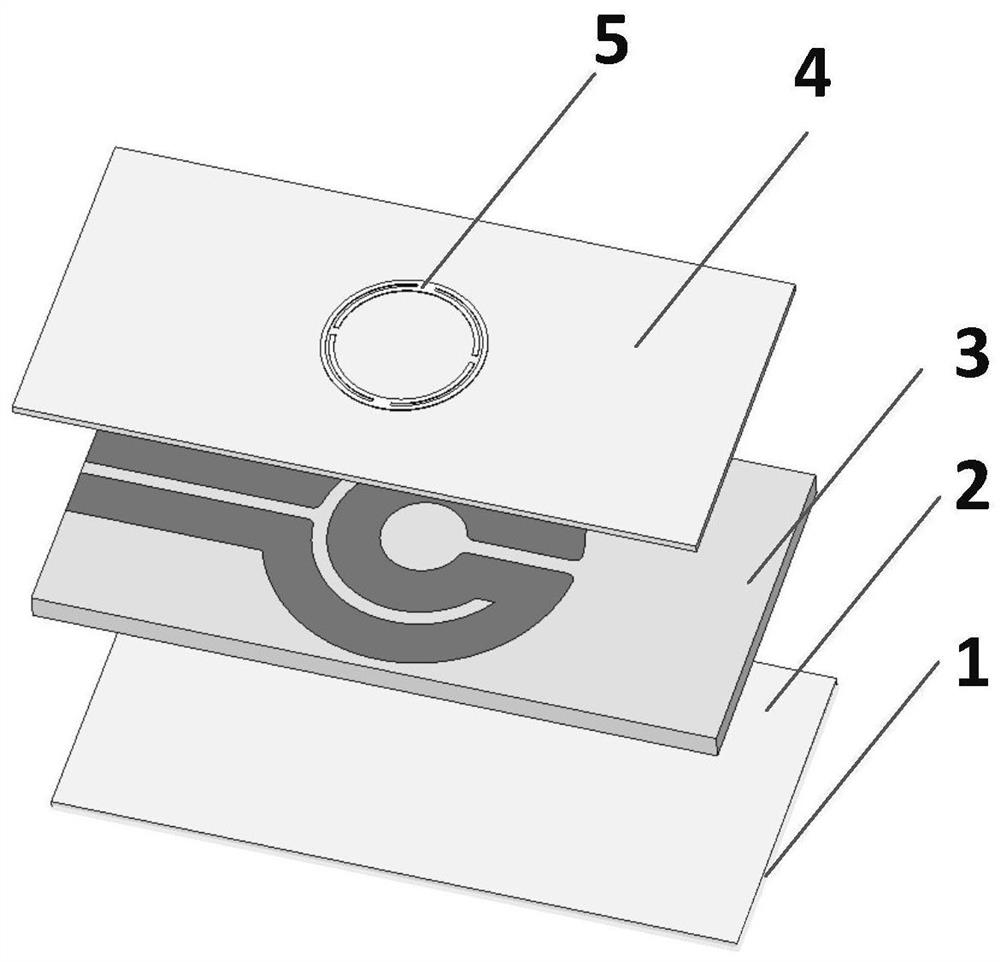

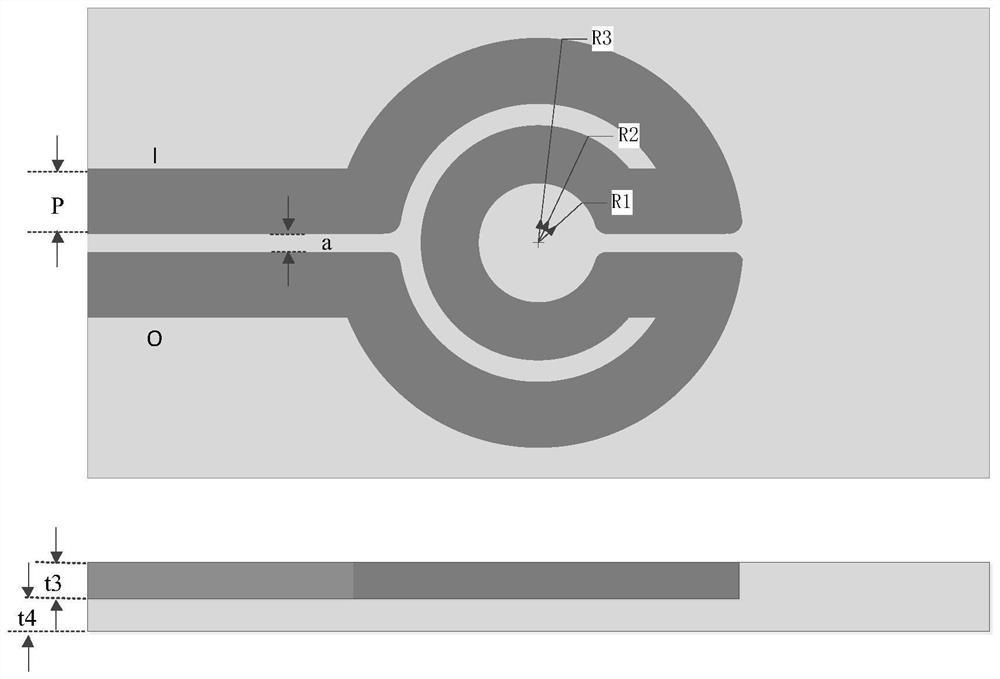

[0028] The wave absorbing sensor involved in the present invention is based on a single resonant unit A to achieve the wave absorbing performance described in the present invention, that is, the metamaterial wave absorbing sensor only includes one wave absorbing resonance unit, such as figure 1 As shown by the rectangular box, electromagnetic waves will be directed into the unit. The metal bottom plate, bottom substrate, microfluidic layer and top substrate in the resonance unit are properly extended in the x and y directions to achieve the purpose of adapting to the size of the test waveguide and form a complete metamaterial wave absorbing sensor. The four through holes at the top corners of the sensor are used to align each layer of the board, and the four upper and lower semicircular through holes are used to assem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com