Thermally insulated synthetic resin container and thermally insulated synthetic resin lid

A technology for synthetic resin and utensils, which is applied in the direction of heat-insulating utensils, containers, and heat-insulating containers, can solve the problems of high cost, long time to complete the process, complicated steps, etc., and achieves the effect of high air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

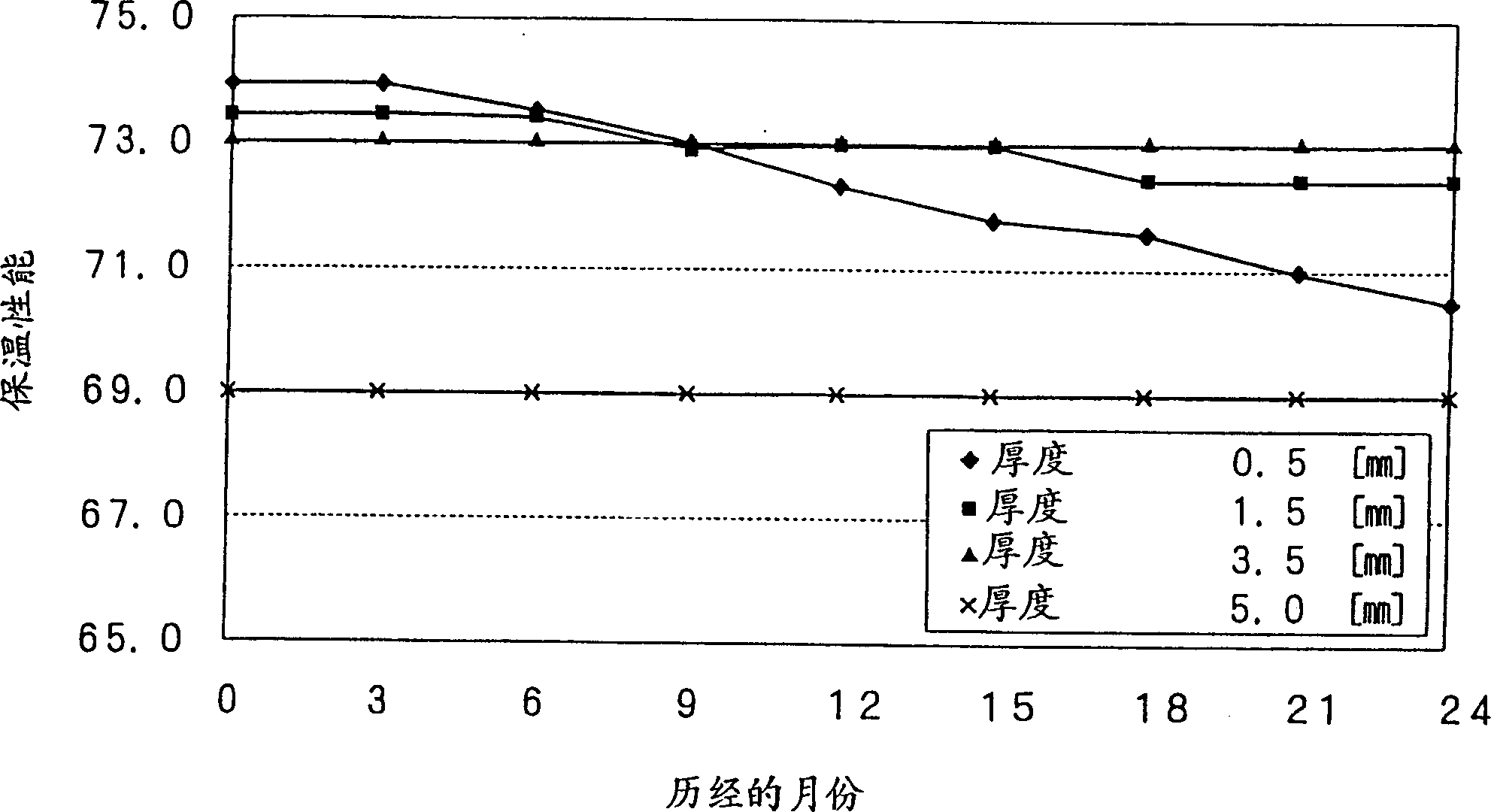

[0050] Polyethylene naphthalene-2,6-dicarboxylate (Mitsubishi Chemical, Inc.,: NC 900 Z), an aromatic polyester, was used to make the heat-insulating vessel 1 . The thickness of the inner vessel 3 and the outer vessel 2 is between 0.5-5.0 mm, and the heat-insulating vessel 1 made of polyethylene naphthalene-2,6-dicarboxylate has different thicknesses of the inner vessel and the outer vessel. Krypton is used as the sealing gas.

[0051] Use these insulated vessels for two years to study how insulation performance changes over time. figure 2 Results are shown. In order to determine the thermal insulation performance of heat-insulating containers, put them in a constant temperature room at 20°C for 1 hour, put hot water at 95°C±1°C in it, cover the heat-insulating lid, and place them in a constant temperature room for 1 hour Then measure the water temperature.

[0052] from figure 2 It can be clearly seen that when the wall is very thin, its thermal insulation performance w...

example 2

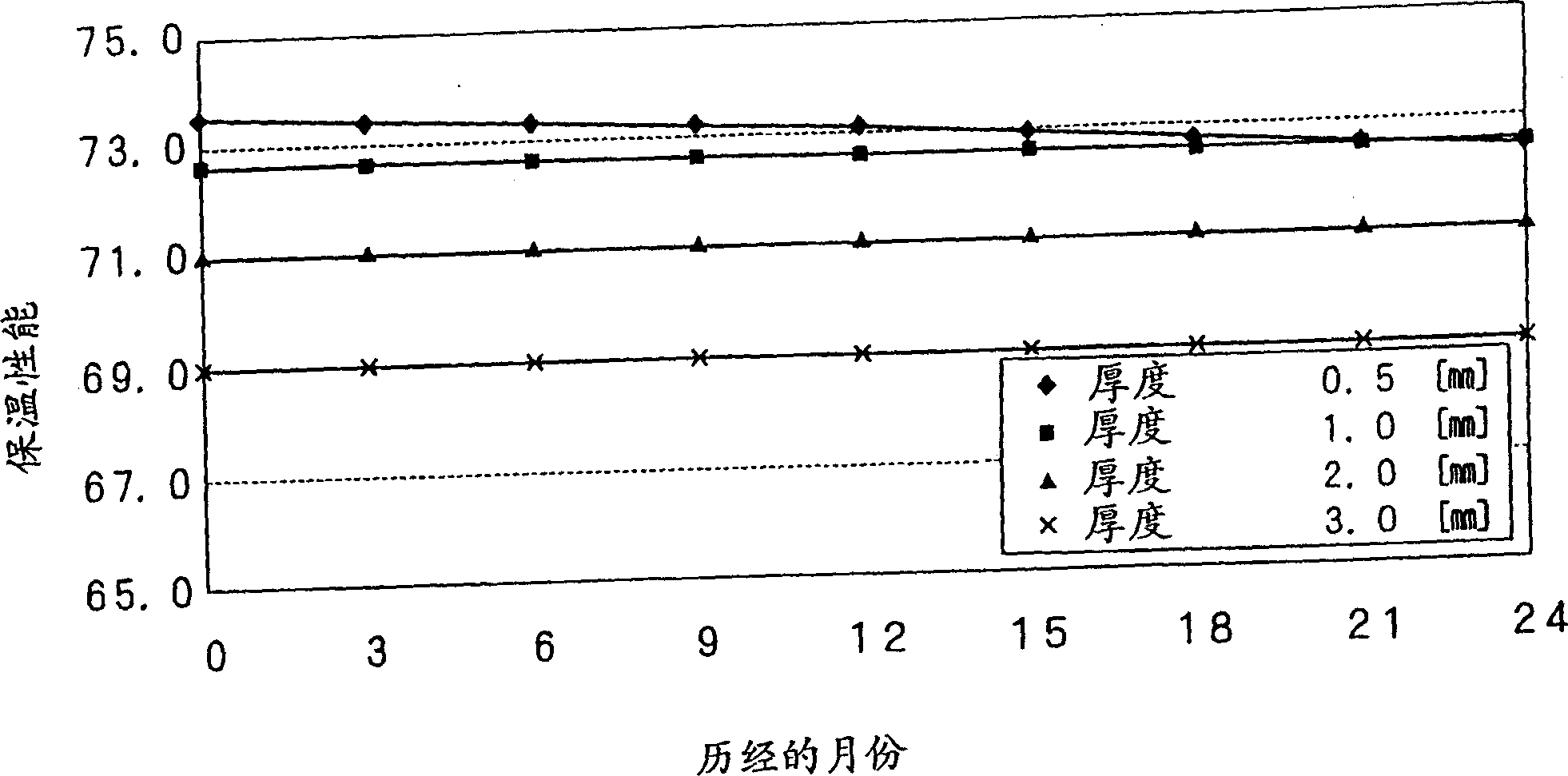

[0056] The heat insulating vessel 1 was made of LCP (Sumitomo Chemical, Inc.,: Sumika Super E6806-WO2), which is a liquid crystal polyester. The thickness of the inner container 3 and the outer container 2 is between 0.5-3.0 mm, and the distance between them is 0.5 mm. The thickness of the inner and outer containers of the heat-insulating container 1 made of LCP is different. Krypton is used as the sealing gas.

[0057] Use these insulated vessels for two years to study how their insulating properties change over time. image 3 Results are shown. In order to determine the thermal insulation performance of heat-insulating containers, as in Example 1, put them in a constant temperature room at 20 ° C for 1 hour, put hot water at 95 ° C ± 1 ° C in it, cover the heat-insulating cover, and place them in the The water temperature was measured after 1 hour in the constant temperature chamber.

[0058] from image 3 It can be clearly seen in the figure 2 Similarly, in order to i...

example 3

[0062] The heat insulating vessel 1 was made of aliphatic polyketone (Shell Japan, Inc.,: Carilon), which is an aliphatic polyketone. The thickness of the inner container 3 and the outer container 2 is between 1.0-2.5 mm, and the thickness of the inner and outer containers of the heat-insulating container 1 made of aliphatic polyketone is different. Krypton is used as the sealing gas.

[0063] Use these insulated vessels for two years to study how their insulating properties change over time. Figure 4 Results are shown. In order to determine the thermal insulation performance of the heat-insulating container, as in Example 1 and 2, put it in a constant temperature room at 20°C for 1 hour, put hot water at 95°C±1°C in it, cover the heat-insulating cover, and place them The water temperature was measured after leaving in the constant temperature chamber for 1 hour.

[0064] from Figure 4 It can be clearly seen in the figure 2 with 3 Similarly, in order to insulate a syn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com